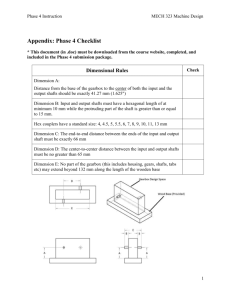

doc - King Fahd University of Petroleum and Minerals

advertisement

King Fahd University of Petroleum and Minerals Mechanical Engineering Department Machine Design I (ME 307) – Second Semester 2006-2007 (062) Course Syllabus 1. ME Mission The department is committed to providing highest quality education in mechanical engineering, conducting world-class basic and applied research, addressing the evolving needs of industry and society, and supporting the development of more competitive and new industry in Saudi Arabia. 2. General Credit 3 hrs Prerequisites CE 203 : Structural Mechanics I; ME 206 : Manufacturing Processes I; ME 210 : Mechanical Engineering Drawing & Graphics Instructors Section 1 (SMW 10-10:50 AM) - Mehmet SUNAR (Room: 22-208, Tel: 4976, E-mail: mehmets@kfupm.edu.sa) Sections 5 (SMW 11-11:50 AM) - Dr. Iyad AL-ZAHARNAH 111, Tel: 4946, E-mail: iyadtz@kfupm.edu.sa) (Room: 22- Section 3 (SMW 9-9:50 AM) - Dr. Khalid AL-DHEYLAN (Room: 22-209, Tel: 1474, E-mail: dheylan@kfupm.edu.sa) Section 2 (SMW 8-8:50 AM) – Mohammad Anis (Room: 23-072, Tel: 4947, E-mail: anisqasm@kfupm.edu.sa) 3. Catalogue Description (2001-2003 Undergraduate Bulletin) Design process, review of stress, strain and deformation analysis as applied to mechanical design; properties of materials; review of static failure theories; designing against fatigue failures; element design; shafts, keys, couplings, power screws; bolted, riveted and welded joints. 4. Prerequisite Knowledge and/or Skills Freebody diagram. Force and moment equilibrium. Stressstrain response and Hooke's law. Force, moment and torque diagrams. Normal and shear stresses in beams and shafts. Mohr s circle & transformation eqs. Stress concentrations. Concept of work and power. Computer graphics. Spreadsheets. 5. Course Objectives 1. To incorporate knowledge learned in the mechanics, structures, materials, and manufacturing courses. 2. To reinforce competence in multi-axis stress analysis and understand the importance of using and interpreting Mohr’s circle to determine principal stresses and maximum shear stresses. 3. To obtain a working knowledge in the use of the proper failure theories under steady and variable loadings. 4. To master the design of mechanical elements, such as shafts, power screws, detachable, permanent and welded connections. 6. Textbook and References Textbook Shigley, J.E., Mischke, C.R. and Budynas, R.G., Mechanical Engineering Design, McGraw Hill, 7th Edition, 2004. References Avallone, E.A. and Maumeister III, T.B., Mark’s Standard Handbook for Mechanical Engineers, McGraw Hill, 10th Edition, 1997. Juvinall, R.C. and Marshek, K. M., Fundamentals of Machine Component Design, John Wiley and Sons, 2000. Mott, R.L., Machine Elements in Mechanical Design, Prentice Hall, 1999. Hamrock, B.J., Jacobson, B. and Schmid, S.R., Fundamentals of Machine Elements, McGraw Hill, 1999. Norton, R.L., Machine Design: An Integrated Approach, Prentice Hall, 1996. Spotts, M.F. and Shoup, T.E., Design of Machine Elements, Prentice Hall, 7th Edition,1998. 7. Course Outline Topic Chapter in Textbook # of Lectures 1. Introduction 1 1 2. Stress Analysis 4 9 3. Deflection and Stiffness Analysis 5 4 4. Failure Theories: Steady Loading 6 4 7 + (3.4) 10 6. Design of Shafts 18 4 7. Design of Screws, Fasteners and Connections 8 9 8. Design of Welded, Brazed and Bonded Joints 9 3 9. Review - 1 5. Failure Theories: Variable Loading Omitted Sections (Not Included) 1.10, Chapter 2 and 3 4.3, 4.11, 4.16, 4.18-21 5.6, 5.9, 5.14-17 6.13, 6.14 7.5, 7.6, 7.15-17 9.8-10, 18.7 8. Assignments Homeworks: Problem sets will be assigned from the textbook and elsewhere. You are expected to work on the homework individually. Homeworks should be submitted in the class on the due time. 9. Computer Usage Students will need to use computers to solve homework problems, since open-ended and iterative problems may be assigned. You may use any software package you are most familiar with. SolidWorks, SolidEdge and MS Excel are possible ones. In due time, you may also be provided with some commercial or inhouse programs to help you with the design process. 10. Attendance Attendance will be checked at the beginning of each lecture. Late coming is not encouraged as this disturbs students and instructor. Excuses for absence should be approved by the Deanship of Student Affairs and submitted to the instructor within one week following the last day of absence. Any student who has more than 9 unexcused absences will get a grade of DN (Denial). Any student who has more than 15 unexcused + excused absences will get a grade of W (Withdrawn) for this course, provided that his unexcused absences are less than 9. 11. Exams The Major and Final Exams will be open book. You will be allowed to prepare one single sheet listing all important formulas that you need. Both sides of the sheet can be used. Major Exam 1: Date & Place: Sat March 24, 2007, at 8:00 pm. Major Exam 2: Date & Place: Sun April 29, 2007, at 8:00 pm. Final Exam: Date, Time and Location: As will be announced by the Registrar. 12. Grading Attendance+Homeworks 9% Quizzes 6% Major Exams Final Exam 13. 50% (2x25) 35% Student Learning Outcomes Course Objective 1 1. Students will demonstrate ability to use free-body diagrams, equilibrium equations, force, moment and torque diagrams, and calculate resulting stresses. 2. Students will demonstrate how to find relevant properties of materials from various sources. Course Objective 2 1. Students will demonstrate ability to compute principal stresses in different machine members subjected to combined loadings. Course Objective 3 1. Students will demonstrate ability to calculate principal stresses and extreme deflections for various cases of loading, and check criteria for failure due to yield or due to unacceptable deflections. 2. Students will demonstrate ability to design thin- and thick-walled cylinders, shrink fitted assemblies, and shafts. Course Objective 4 1. Students will demonstrate ability to apply stress and deflection analyses, failure criteria under steady and variable loadings, in applications involving the design of simple machine elements, such as shafts, power screws, and various connections.