Phase 4 Checklist

advertisement

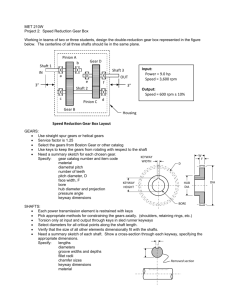

Phase 4 Instruction MECH 323 Machine Design Appendix: Phase 4 Checklist * This document (in .doc) must be downloaded from the course website, completed, and included in the Phase 4 submission package. Dimensional Rules Check Dimension A: Distance from the base of the gearbox to the center of both the input and the output shafts should be exactly 41.27 mm (1.625") Dimension B: Input and output shafts must have a hexagonal length of at minimum 10 mm while the protruding part of the shaft is greater than or equal to 15 mm. Hex couplers have a standard size: 4, 4.5, 5, 5.5, 6, 7, 8, 9, 10, 11, 13 mm Dimension C: The end-to-end distance between the ends of the input and output shaft must be exactly 66 mm Dimension D: The center-to-center distance between the input and output shafts must be no greater than 65 mm Dimension E: No part of the gearbox (this includes housing, gears, shafts, tabs etc) may extend beyond 132 mm along the length of the wooden base 1 Phase 4 Instruction MECH 323 Machine Design Shafts and Bushings Check Shafts have been sized to fit inside bushings Bushing part numbers have been provided in the McMaster-Carr Order From (below) and the appropriate bushings present in the CAD model Shafts provide adequate room for, and a method of transmitting torque to, gears Shaft design allows for assembly Input and output shafts are placed on correct sides of housing Housing Check Housing looks robust enough to not break. CAD model is well made and includes no broken features Housing provides some method of alignment between the two or more components No protrusions from the housing are smaller than 2-3mm (too small features will not be printed properly.) Housing includes spots for screws to mount to the wooden base and access room for tools (if using supplied screws then holes are sized for M6 screws of ½” length) Housing can be assembled/disassembled Housing includes bearing (i.e. bushings in Phase 4) bores, and shoulders to keep bearings (i.e. bushings in Phase 4) from coming out Printing Time Check Catalyst print time is under 8 hours Catalyst print time is clearly and explicitly indicated in “Group X Phase 4 Report.PDF” document. 2 Phase 4 Instruction MECH 323 Machine Design Printing Orientation Carefully read Phase 4 instructions, and choose one of the two following options. Option Check (1) Standard orientation as specified in Table 1 in Phase 4 Instructions Do NOT include “Group X Printing Instructions.PDF” document (2) Custom orientation that is different from the standard in Table 1 in Phase 4 Instructions You must include “Group X Printing Instructions.PDF” document in your submission package McMaster-Carr Order Form ID (shaft diameter) OD (outer diameter) Length McMaster-Carr Part Number Price/Unit Quantity Total Price: Assembly and Testing of Your 3D Prototype Carefully read Phase 4 instructions, and choose one of the two following options. Option Check (1) Student Testing You must sign up for a testing session by sending an email to bradley.taylor@queensu.ca. (First come, first served.) (2) TA testing Further manufacturing processes (e.g. drilling) are not allowed. 3