Course Description

advertisement

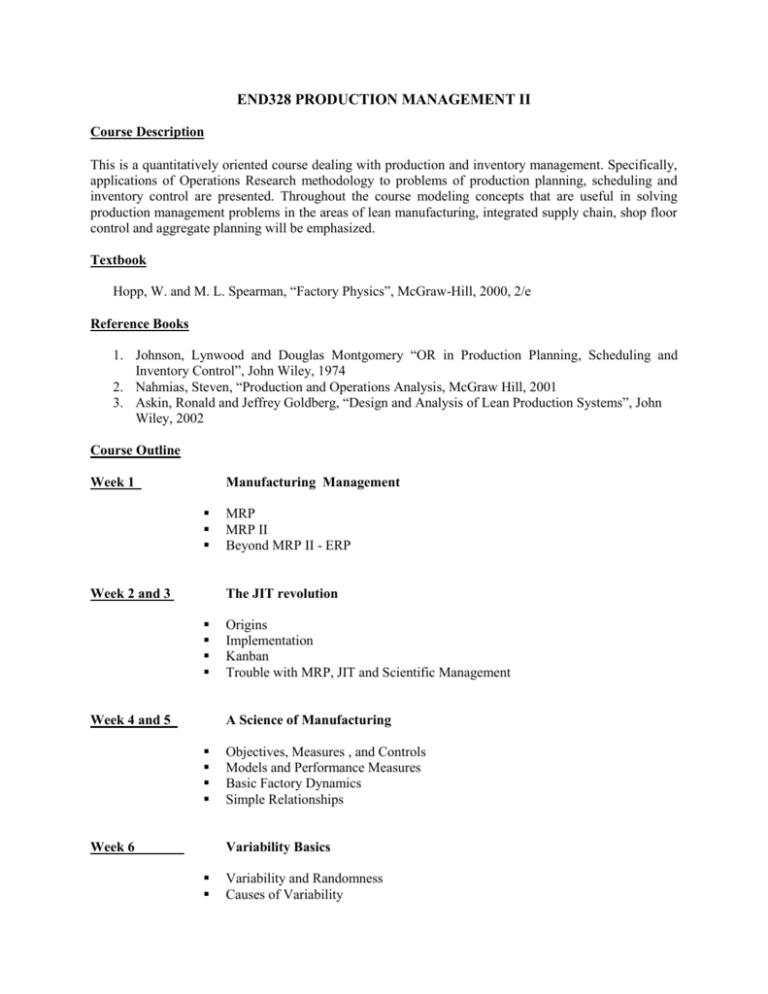

END328 PRODUCTION MANAGEMENT II Course Description This is a quantitatively oriented course dealing with production and inventory management. Specifically, applications of Operations Research methodology to problems of production planning, scheduling and inventory control are presented. Throughout the course modeling concepts that are useful in solving production management problems in the areas of lean manufacturing, integrated supply chain, shop floor control and aggregate planning will be emphasized. Textbook Hopp, W. and M. L. Spearman, “Factory Physics”, McGraw-Hill, 2000, 2/e Reference Books 1. Johnson, Lynwood and Douglas Montgomery “OR in Production Planning, Scheduling and Inventory Control”, John Wiley, 1974 2. Nahmias, Steven, “Production and Operations Analysis, McGraw Hill, 2001 3. Askin, Ronald and Jeffrey Goldberg, “Design and Analysis of Lean Production Systems”, John Wiley, 2002 Course Outline Week 1 Manufacturing Management Week 2 and 3 MRP MRP II Beyond MRP II - ERP The JIT revolution Week 4 and 5 Origins Implementation Kanban Trouble with MRP, JIT and Scientific Management A Science of Manufacturing Week 6 Objectives, Measures , and Controls Models and Performance Measures Basic Factory Dynamics Simple Relationships Variability Basics Variability and Randomness Causes of Variability Variability Interactions-Queueing Effects of Blocking Week 7 Midterm I Week 8 The Corrupting Influence of Variability Week 10 and 11 Performance and Variability Flow Laws Batching Laws Cycle Time Push and Pull Production Systems The Pull CONWIP Comparisons of CONWIP with MRP and Kanban A Pull Planning Framework Week 12 Midterm II Week 13 Shop Floor Control Week 14 CONWIP Configurations Other Pull Mechanisms Production Tracking Production Scheduling Operations Scheduling Scheduling System Requirements Order Release Strategies Single Machine Scheduling Flow Shop Scheduling Job Shop Scheduling Shop Floor Control Grading: 2 midterms, each 25%, assignments 10%, and final 40%