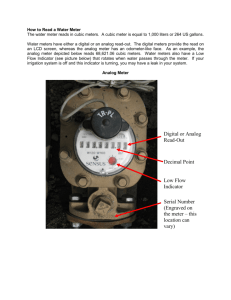

NMI M 10-1 Meters Intended for the Metering of Water in Full

advertisement