2010 bio301 exam

advertisement

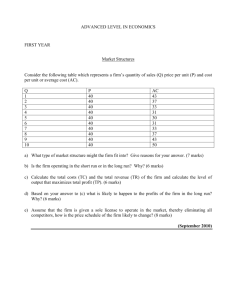

2010 Bio 301 Final Exam Student No………………………Name………………………. 40 Total Marks in 3 Sections (5 + 6.5 + 12.5 + 6) Generate a new plot figure to replace question Section 1: (5 marks) Answer all of the 5 questions on Algal Biotechnology below: 1.1 (0.1 marks): In heterotrophic growth, what is the energy source(s) for algal growth? 1.2 (0.1 marks): What effect does photosynthetic CO2 uptake have on the pH of the culture? 1.3 (0.1 marks): Why is phosphate an important nutrient for algae? 1.4 (0.4 marks): What are the main factors which would give a type II response in algal cultures? 1.5 (0.1 marks): If you add nitrate, ammonia and urea to a culture which of these would the algae take up first? 2009 Bio301 final test 1/14 1.6 (0.2 marks): Define the specific growth rate μ in terms of the doubling time, t2. What is the unit for μ ? 1.5 Algal Growth (4 marks) The growth curve below is for a culture of Dunaliella salina grown in a 25 L airated carboy-type photobioreactor in the laboratory. The growth conditions were: Temperature : 25 ± 2) oC Light: 165 μmol photons.m-2.sec-1 (supplied by cool-white fluorescent lights) on a 12h light: 12h dark cycle. Initial pH: pH 8.1 Composition of the medium (all concentrations are in g.L-1) NaCl 150.0 MgCl2.2H2O 1.5 MgSO4.7H2O 0.5 CaCl2.2H2O 0.2 KCl 0.2 NH4Cl 0.1 H3BO3 0.061 MoO3 0.015 CuSO4.5H2O 0.006 MnCl2.4H2O 0.004 ZnCl2 0.004 Write brief answers to each of the following questions (all are of equal value): (a) How would you change the culture conditions to increase the growth rate; (b) How would you change the culture conditions to achieve a higher final cell yield; (c) What could be done to maximise the content of β-carotene per cell; 2009 Bio301 final test 2/14 Section 2: (6.5 marks) Answer all of the 2 questions below: 2.1 Laboratory chemostat operation (2 marks) In the laboratory class chemostats were operated for the production of…………….. In terms of process control it was particularly important for this chemostat to control the ………………. to a value of about………….. .. This was important for the product production because without this control the likely consequences would have been that…………. ……………. ……………….. ……………… …………….. …………. ………………. ……………. The energy source (electron donor and acceptor to the bacteria) was ………… ………… …………. ……….. A computer was connected to the chemostat which allowed the following to be carried out automatically ………………………. ……………………… and to record continuously………. The product was quantified by measuring ……….. …………. ………….. This measurement is based on the conversion of …………. …………… to ………….. …………….. ……………….. …………….. An example of a particular technical problem encountered by some groups was…………. ………….. 2009 Bio301 final test 3/14 2.1 Bioprocess analysis (4.5 marks) An aerobic chemostat was operated at room temperature to degrade the pollutant propanol (CH3-CH2-CH2OH) to CO2. The chart below shows the dissolved oxygen concentration plotted against time. At 100 seconds the air supply was stopped. 1. What is the current propanol degradation rate? 2. Is the chemostat limited by the oxygen supply capacity or by the bacterial activity? Explain your answer. 3. What is the maximum possible propanol degradation rate of this particular chemostat based on its oxygen supply capacity? 4. What is the kLa value of the chemostat? 5. Estimate the critical dissolved oxygen concentration of the bacteria OR their oxygen half saturation concentration (kS) 2009 Bio301 final test 4/14 Section 3: (12.5 marks) Answer 5 out of the following 6 questions. Each question carries 2.5 marks 3.1 Microbial Growth and Cultivation (10 min) (a) List the four growth constants of microbes (with units) that allow the prediction of their growth. (b) Demonstrate with a plot of specific growth rate against substrate concentration , an example of high and low values of the growth constants. (use a dotted line for a low value and a solid line for a high value of each growth constant). Point out on this plot where the specific substrate concentration is and what explain what it means. 2009 Bio301 final test 5/14 3.2 Control of bioprocesses (10 min) Microbial processes need to be controlled very strictly in many cases. High cell density cultures of E. coli, SND and anaerobic digestion were examples requiring control Explain for two of the processes: a) what needs to be controlled b) what needs to be measured c) why the control is needed (e.g. what happens if the to be controlled variable is too high or too low d) the industrial significance of the process High cell density cultures require high level of oxygen and feed supply. Towards the end of the culture feed supply is given “on demand” as both, over supply and under supply will mean the process does not run optimally. 1. Explain how such an “on demand” feed supply can be done by using feedback control loops based on oxygen measurements. Give instruction detailed enough to allow a technician to operate the process under optimum conditions 2. Give an example where this feeding technology is used and what the problems are when too much feed is added. 2009 Bio301 final test 6/14 3.3 Fermentation pathways (10 min) Homolactic and ethanolic fermentations both use glucose as the carbon source in the absence of oxygen. a) Explain the principle of electron flow of a fermentation pathway such as ethanolic or homolactic fermentation. b) What is the electron donor, what is the acceptor ? c) Why would we expect a lot less growth by fermentation than by aerobic metabolism of glucose ? d) Estimate much less growth would we expect ? Under anaerobic conditions bacteria can use different pathways of sugar fermentation. Explain either the butyric acid fermentation, homoacetogenic fermentation or the acetone butanol fermentation in terms of characteristic electron flow. Explain what the electron acceptors are that will be reduced by NADH formed from glycolysis. 2009 Bio301 final test 7/14 3.4 Advanced Nitrogen Removal (10 min) Explain the principle microbial reactions involved in of nitrogen (as ammonia) removal from wastewater. Sketch the relative effect oxygen concentration (on the x-axis) on the rate of nitrification and denitrification (on the y-axis). And explain from the sketch how simultaneous nitrification and denitrification can be accomplished. How could the process of simultaneous nitrification and denitrification be controlled on-line? Explain the principle and benefits of simultaneous nitrification and denitrification via nitrite. Refer to the oxidation states of the nitrogen species involved to quantify your explanation. 2009 Bio301 final test 8/14 3.5 Anaerobic Digestion Failure (10 min) Anaerobic digestion is a process than can convert organic material into a renewable fuel (CH4). However it is a process that can go wrong resulting in digester failure due to overloading. The overloading is typically caused by electron donors for methanogenesis becoming available 1. Explain the principle of electron flow during anaerobic digestion during successful operation and during failure. 2. Explain in detail the reasons for digester failure by referring to the energetics (Gibbs Free Energy Change) of the key reactions. 3. Describe a possible on-line control strategy that could help controlling the anaerobic digestion process to avoid failure due to overloading. a. What will be measured? b. What will be controlled? c. What type of algorithm (use words or flow diagram) could be used? 2009 Bio301 final test 9/14 3.6 Process monitoring and control (10 min) A proportional- integral- differential controller (PID) can be used in bioprocesses to control process parameters such as dissolved oxygen concentration or pH to a desired set-point. 1. Explain how the three different elements (P, I, D) work and give at least one advantage and one disadvantage of each element. 2. Give an example of a process, parameter to be controlled and the need for its control. 2009 Bio301 final test 10/14 Section 4: Short answer questions (6 marks) Answer 6 out of the following 8 questions. Each question carries 1 mark 4.1 Floc formation (5 min) Bacteria do not always grow as a suspended culture. They can “stick together” to form either biofilms or aggregates (flocs). 1. Give two examples where the floc formation is desired in industrial bioprocesses. 2. Give an example of how floc formation can be encouraged. 3. How can the fact that microbes flocculate be used to improve process conditions in a continuous flow or sequencing batch reactor 4.2 Reactor types (5 min) A number of different bioreactor types have been covered in this unit. Explain the key differences and potential uses and disadvantages of these processing types, giving at least one example for each 1. Batch culture 2. Chemostat culture 3. Sequencing batch reactor 4. Fed batch culture 5. Fixed film reactor 2009 Bio301 final test 11/14 4.3 Biofuel (5 min) Both, algae and bacteria can be used to generate biofuels. Point out key differences between the two approaches (“pros and cons”). Point out what the electron donor and acceptors are both phototrophic and heterotrophic energy metabolism. 4.4 Product Yield Prediction (5 min) The aerobic oxidation of a brewery wastewater consisting essentially of 20 mM ethanol (CH3-CH2OH) solution as the organic pollutant will require how much oxygen per L of wastewater? Refine your answer by a) neglecting and b) including the likely growth of microbial cells. 2009 Bio301 final test 12/14 4.5 Electron Balance (2 min) The anaerobic digestion of an organic substance produced 50 L of methane gas. How much oxygen would have been necessary to degrade the same compound? 4.6 Process monitoring and control (10 min) A proportional- integral- differential controller (PID) can be used in bioprocesses to control process parameters such as dissolved oxygen concentration or pH to a desired setpoint. Explain how the three different elements (P, I, D) work. Why is an on-off controller normally not adequate? Why is a purely proportional controller or a purely differential controller alone not adequate? Give an example of a process that needs tight process control 2009 Bio301 final test 13/14 4.7 Bioenergetics (5 min) Under which conditions are reducing equivalents (e.g. reduced electron carriers such as NADH) an energetic advantage or disadvantage for bacterial cells? Give examples. 4.8 Bio-geo-chemical cycles (5 min) Sketch with a simple scheme how the microbial oxidation and reduction of sulphur species can establish a local sulphur cycle, such as on the surface of marine or freshwater sediments. What are the electron donors and acceptors for the reactions? Why can it be said that the sulphur metabolism “mediates” and electron flow from organic compounds to oxygen? ---------- End of paper ----------- 2009 Bio301 final test 14/14