doc

advertisement

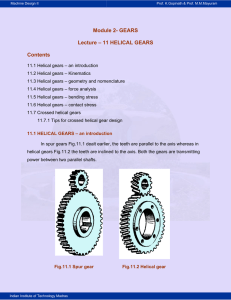

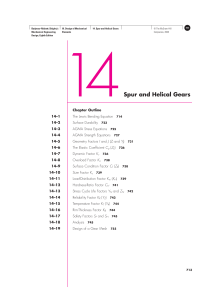

KING FAHD UNIVERSITY OF PETROLEUM & MINERALS Department of Mechanical Engineering ME 308 Machine Design II 2006-2007 (061) ME Mission The department is committed to providing highest quality education in mechanical engineering, conducting world-class basic and applied research, addressing the evolving needs of industry and society, and supporting the development of more competitive and new industry in the Kingdom of Saudi Arabia. Catalog Description Design of Elements: bearings (journal and anti-friction); spur, helical, bevel and worm gears; flexible drives (belts and chains); clutches and brakes; Springs; design optimization. Laboratory sessions to supplement and to apply the material covered in the lectures. Consideration of manufacturing aspects of the design (limits and fits); projects in stages leading to an assembly. Instructor Dr. Abdel-Salam M. Eleiche Bldg. 22-237 Phone: 860-3765 E-mail: eleichea@kfupm.edu.sa Office Hours SUMTW: 1-2 pm Text Mechanical Engineering Design by J.E. Shigley, C.R. Mischke and R. G. Budynas, 7th ed. References 1. Standard Handbook of Machine Design by J.E. Shigley and C.R. Mischke, McGraw Hill Book Company. 2. Mark’s Standard Handbook For Mechanical Engineers, by Avalone Baumeister, 10th Ed. McGraw Hill Book Company. 3. Machine Elements in Mechanical Design, by R. L. Mott, 2nd Ed. Prentice Hall 4. Fundamentals of Machine Components Design, by R. C. Juvinall and K. M. Marshek, 2nd Ed. John Wiley. 5. Fundamentals of Machine Elements, by B. J. Hamrock, Bo Jacobson and S. R. Schmid, 1st Ed., McGraw Hill Book Company. 6. ME-308 Laboratory Manual, (General Design Procedures and Guidelines) Course Objectives 1. To analyze mechanical systems and select proper machine elements (bearings, gears, springs, belts and pulleys, chains and sprockets). 2. To design machine elements by specifying their type, geometry, material and heat treatment and how to integrate these elements to build a mechanical system. 3. To learn how to work in a design team and to understand group dynamics 4. To perform a complete project and present his work in an engineering design report. Prerequisites This is the second course of machine design. In the first course (ME 307), the student is expected to have learned: Stress and deflection analysis Buckling Static and fatigue failure criteria Analysis and design of bolted and welded joints Shaft design and analysis The student is also expected to be able to use SOLIDWORKS (or AutoCAD) to perform drawings of machine elements and systems (ME 210). Course Outline 1. Rolling contact bearings 2. Spur gears 3. Helical worm and bevel gears 4. Strength of Spur and Helical gears 5. Lubrication and journal bearings 6. Clutches, brakes, couplings and flywheels 7. Belts and chain drives Reading Assignments: Chapter Chapter 11 Chapter 13 Chapter 13 Chapter 14 Chapter 12 Chapter 16 Chapter 17 (# lectures) (6-7) (5-6) (3-4) (5-6) (8-9) (8-9) (4-5) Sections: 11.7; 13.8; 16.6; 17.6 and 17.7. Omitted Material : Measurement of viscosity (p. 610); cross helical gears (689); sections 14.1, 14.2; 16.11 and 16.12. Evaluation: All Exams (including the Final) and Quizzes will be OPEN book 1. MAJOR and FINAL EXAMS: There will be two open book major exams containing open-ended problems. Major Exam 1: Tuesday 31-10-06, 7-9 pm, Location: TBA. Major Exam 2: Tuesday 5-12-06, 7-9 pm, Location: TBA. Final Exam: Sunday 21 Jan. 2007, 7 pm, Location: TBA. 2. ATTENDANCE: Attendance will be closely monitored, according to University regulations. 3. HOMEWORKS: Homework will be assigned, collected and graded. Late submissions will NOT be accepted. 4. LAB ASSIGNMENTS: Laboratory sessions will be conducted in parallel with lectures and will include long projects. Your achievement and progress during class time will be graded by the end of each Lab. A final report for every project is also required and will be graded as well. When a new project is assigned the former one will be collected for grading. Late submissions will NOT be accepted. 5. RELATIVE WEIGHTS AND GRADING: * Homework & attendance 7% * Quizzes (4-6) 8% * Lab Projects 15% * Lab. participation 10% * Major Exams (2) * Final Exam 30% (15% each) 30% Student Learning Outcomes Objective 1 1. The student is expected to analyze mechanical systems and select the proper machine elements (bearings, gears, pulleys, belts, …) from commercial catalogs for a required application. Objective 2 2. The student is expected to be able to analyze proposed design solutions and suggest modifications and improvements. 3. The student should be able to execute original designs of machine elements. 4. The student should be able to produce design sketches and integrate the designed or selected elements into a working mechanical system. Objective 3 5. The student will be able to hold and lead efficient design team meetings 6. He is expected to write minutes Objective 4 7. The student will be able to implement design procedures to perform complete design projects individually or in a team. 8. The student is expected to communicate the implemented design ideas by performing production CAD drawings, writing technical reports and making oral presentations.