Gears and Spline Shafts Francesca Ferzoco 20196585

advertisement

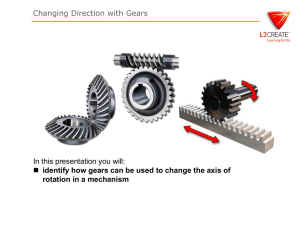

Gears and Spline Shafts Francesca Ferzoco 20196585 Objectives • To introduce the main types of gears and spline shafts that might be seen on work terms • To explain the functions of gears and spline shafts Gears: Functions • They provide a gear reduction in motorized equipment 1.To reverse the direction of rotation 2.To increase or decrease the speed of rotation 3.To move rotational motion to a different axis 4.To keep the rotation of two axes synchronized Gears • The gear ratio is determined by the distances from the center of the gear to the point of contact • Many modern gears use a special tooth profile called an involute • The pitch diameter is the effective contact diameter • An involute profile gear tooth produces a constant ratio of rotational speed Gears: Main Types • Spur Gears • Helical Gears Crossed Helical Gears Gears: Main Types • Bevel Gears • Hypoid Gears Spiral Bevel Gears Gears: Main Types • Worm Gears • Rack and Pinion Gears Spline Shafts • Have either grooves or tongues machined along its length • The mating bearings run along either the groove or tongue, providing high rigidity Spline Shafts: Main Types • • Ball Spline Bearing Spline Bushing Bearing Summary • Gears: Functions 1. 2. To reverse the direction of rotation To increase or decrease the speed of rotation 3. To move rotational motion to a different axis 4. To keep the rotation of two axes synchronized • Gears: Main Types Spur Gears Helical Gears Bevel Gears Hypoid Gears Worm Gears Rack and Pinion Gears • Spline Shafts: Main Types Spline Bushing Bearing Ball Spline Bearing References • http://science.howstuffworks.co m/gear.htm • http://bearings.globalspec.com/ Specifications/Mechanical_Co mponents/Bearings_Bushings/L inear_Guides_Rails