Non-chlorine Sanitizer Options for the Wineries

advertisement

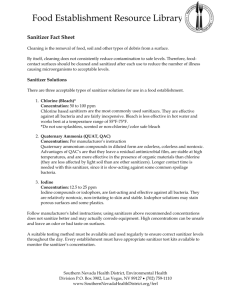

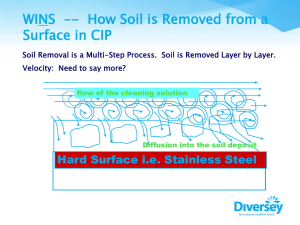

Non-chlorine Sanitizer Options for the Wineries Dr. Randy W. Worobo Department of Food Science & Technology New York State Agricultural Experiment Station Cornell University Geneva, NY 14456 Dr. Worobo joined the Department of Food Science and Technology at Cornell University in August 1997 as an assistant professor of food microbiology. He obtained his Ph.D. in Food Microbiology at the University of Alberta in Edmonton, Alberta, Canada in 1995. Dr. Worobo was awarded a French Foreign Ministry Scholarship and carried out his postdoctoral work on antimicrobial peptide resistance mechanisms of Listeria monocytogenes at the Pasteur Institute and the Institute for Molecular Biology and Genetic Engineering in France. In 1997 he joined the Department of Food Science & Technology at Cornell University. Research areas of interest include non-thermal processing alternatives for beverages; pathogen survival in manure and manure amended soil and decontamination treatments for fruits and vegetables. Dr. Worobo has extensive knowledge in plant sanitation and has worked with various industries on sanitation programs. Other research interests include bacterial antimicrobial proteins and peptides, termed bacteriocins that are capable of inhibiting foodborne pathogens and spoilage organisms. With the recent discovery that chlorinated compounds contribute to the development of TCA in wine, the industry has avoided the use of any chlorinated sanitizers in the winery. Chlorinated sanitizers are commonly used in other sectors of the food and beverage industry as well as in hospitals, institutional settings and in consumer’s homes. The wide usage of chlorine is because of it’s broad germicidal spectrum, short killing time, low concentration required for killing, and is very inexpensive. The selection of alternative non-chlorinated sanitizers in wineries must be carefully evaluated for the intended application and desired end result. Non-chlorinated sanitizer options include: Quaternary Ammonium Compounds (QUATS) Iodine based sanitizers Acid anionic sanitizers (Peracetic Acid) Hydrogen Peroxide Heat Each of the listed sanitizers have benefits as well as limitations. Proper cleaning of equipment and surfaces with detergents prior to application of the selected sanitizer is extremely important. In addition, the correct preparation, concentration and application of the sanitizer, increases the efficacy of the sanitizer. 33rd Annual New York Wine Industry Workshop 147 Quaternary ammonium compounds are excellent for sanitizing walls, floors and furnishings. The have good penetration ability so are one of the most effective sanitizers for porous surfaces such as wood. QUATS are stable at higher temperatures and have long acting germicidal effects. Unfortunately, QUATS are not broad spectrum and are ineffective against spores and Gram negative bacteria. They also require long contact times to exert its germicidal action. Iodine based sanitizers are faster acting than QUATS and are also broader spectrum against Gram positive and Gram negative bacteria but are minimally against bacterial spores. Iodine based sanitizers have poor efficacy at low temperatures and ideal usage temperatures are 50-65°C. Iodine are generally non-reactive with equipment but can discolor plastic over periods of continued use. Organic matter inactivates iodine so it is important that proper cleaning prior to application of the iodine sanitizer is performed. Peracetic acid based sanitizers are increasing in popularity in the dairy, beverage, food processing industry and wine industry. Challenge studies have shown that peracetic acid is a rapid, broad spectrum sanitizer that is effective against yeast, mold and bacteria. Because of its particular effectiveness against yeast and molds, it has gained acceptance in the soft drink and brewing industry. Disadvantages of peracetic acid include high cost, odor irritancy, corrosive nature and inactivation by organic matter. Recently, hydrogen peroxide has been approved by the EPA as a sanitizer. A maximum concentration of 1,100 ppm is permitted and has been shown to be effective at higher concentrations against biofilms that develop in food processing plants. In combination with peracetic acid, this combination provides a broad spectrum of activity against bacteria, yeast and mold. Hydrogen peroxide breaks down to water and oxygen without the generation of any undesireable by-products. However, hydrogen peroxide degrades quickly, especially when exposed to ultraviolet light. Sanitizer solutions containing hydrogen peroxide must be made fresh and used within a short period of time. Thermal sanitizing by steam or hot water are two of the simplest and most effective means to kill yeast. Reaching a temperature of 80°C is sufficient to inactivate contaminating yeast as well as the majority of vegetative bacteria. Careful attention must be paid to the end-point temperature to ensure adequate inactivation of contaminating microorganisms. The major drawback of thermal 33rd Annual New York Wine Industry Workshop 148 sanitation is the energy demands required to produce the steam or for heating the large volumes of water. To ensure an effective sanitation program, a proper cleaning and sanitation regime must be followed. The five step process includes 1. rinsing of excess organic material off of the equipment surface 2. application of detergent and scrubbing to lift off organic material 3. rinsing with water to remove detergent and organic material 4. application of desired sanitizer at recommended concentration for the specified time 5. rinsing with potable water Regardless of what sanitizer you choose, it is a good practice to identify what your problematic microorganism is and select the appropriate sanitizer. It is also beneficial to rotate sanitizers (at least two different classes) on a weekly base. Sanitizer rotation prevents build-up of a microbial flora that is not sensitive to the selected sanitizer. This presentation will cover in depth the sanitizer options available for wineries and considerations that must be taken for each regime. 33rd Annual New York Wine Industry Workshop 149