Structural Analysis of Stresses Transferred to a Basketball

Backboard from the Rim by Human Loads

by

Ryan Ansaldo

An Engineering Report Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING IN MECHANICAL ENGINEERING

Approved:

_________________________________________

Ernesto Gutierrez, Project Adviser

Rensselaer Polytechnic Institute

Hartford, Connecticut

August, 2012

i

© Copyright 2012

by

Ryan Ansaldo

All Rights Reserved

ii

CONTENTS

LIST OF TABLES ............................................................................................................ iv

LIST OF FIGURES ........................................................................................................... v

ACKNOWLEDGMENT .................................................................................................. vi

ABSTRACT .................................................................................................................... vii

1. Introduction.................................................................................................................. 1

1.1

Background ........................................................................................................ 1

1.2

Problem Description........................................................................................... 2

2. Methodology ................................................................................................................ 3

2.1

Abaqus Finite Element Analysis ........................................................................ 3

2.2

Finite Element Development Model .................................................................. 4

2.2.1

Two Part Backboard and Constraints..................................................... 4

2.2.2

Backboard and Rim Constraints ............................................................ 5

3. Results and Discussion ................................................................................................ 5

4. Conclusion ................................................................................................................... 8

5. References.................................................................................................................... 9

iii

LIST OF TABLES

Table 1: Material Properties .............................................................................................. 2

iv

LIST OF FIGURES

Figure 1: Geometry of backboard and rim modeled in Abaqus/CAE ............................... 3

Figure 2: Backboard sections and highlighted shell-to-solid coupling ............................. 4

Figure 3: Bolt pattern of rim and backboard with constraints highlighted (orange) ......... 5

Figure 4: Boundary Conditions and Load ......................................................................... 6

Figure 5: Von Mises Stresses on Tempered Glass Backboard .......................................... 7

Figure 6: Displacement in the z-direction of the Tempered Glass Backboard .................. 7

v

ACKNOWLEDGMENT

Type the text of your acknowledgment here.

vi

ABSTRACT

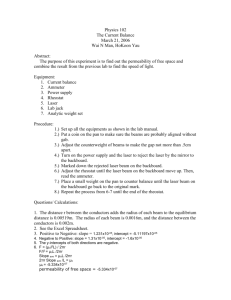

The purpose of this project is to perform a structural analysis of a basketball rim

assembly and investigate the type of stresses imparted on the backboard from the rim.

The structural analysis on the rim and backboard mount was performed using

Abaqus/CAE to compare the stresses applied to a backboard of common backboard

materials. The three backboard materials of interests are tempered glass, acrylic, and

steel.

vii

1. Introduction

1.1 Background

Basketball is a popular sport played all over the world. Since its invention, the sport has

gone through many evolutions. The original “basket” was in fact an actual peach basket

and was nailed to the wall. In modern times, the basket has been replaced by a rim and

net and has a more sophisticated means of being fastened to the backboard. The athletic

ability of basketball players has also changed over the years and since the invention of

the dunk shot, the basketball rim and backboard have been subjected to many changes

and redesigns.

Previously the only loads applied to the basketball rim were imparted by the ball which

has a weight of approximately 22 ounces (Reference 1). When a dunk is performed,

depending on whether or not a player decides to hang, the rim can experience loads in

the magnitude of the weight of an above average human weight (since many collegiate

and professional basketball players are above average height and weight). The force is

then transferred to the bracket which mounts the rim to the backboard.

The stress experienced by the backboard is something that still affects the design of

modern day rims as the consequences are not only catastrophic for its function but

potentially harmful. Professional basketball rims are made of glass and have shattered

when being overstressed. For this reason, the basketball rim and mount are constantly

redesigned to improve the function of the rim. Since basketball has also become a

recreational outdoor sport, the materials of backboards have also changed.

1

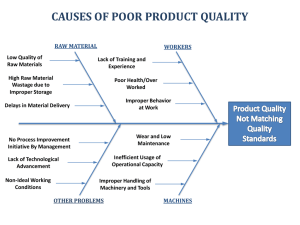

1.2 Problem Description

For this project, a structural analysis of a basketball rim and backboard were performed.

The load is assumed to be applied at the point on the rim furthest from the backboard to

simulate the greatest possible moment. The geometry of the assembly was modeled and

analyzed in Abaqus/CAE. The load is assumed to be 325 lbs, which is the weight of

retired NBA player Shaquille O’Neal (Reference 2). The three backboard materials of

interests are tempered glass, acrylic, and steel.

Table 1: Material Properties

Material

Modulus of Elasticity (psi)

Poisson’s ratio (ʋ)

Tempered Glass

10,000,000

0.22

Acrylic

290,075

0.37

Steel

27,557,170

0.27

2

2. Methodology

2.1 Abaqus Finite Element Analysis

The geometry of the basketball rim and backboard were modeled in Abaqus/CAE using

the dimensions of standard regulation sized rim and backboard. The design chosen is of

a rim with no breakaway feature and assumes the load is directly transferred from the

rim to the backboard. The mounting bracket will be modeled to be bolted to the

backboard using the appropriate constraints. Rigid body tie constraints will be used to

simulate the connection between the bolted connection and the backboard.

Step 1:

After the design was chosen, it was modeled in Abaqus/CAE using the regulation

dimensions of a basketball rim and backboard. A common bolt pattern was used for an

accurate simulation of the interaction between the rim and backboard. The figure below

shows the geometry in Abaqus.

Figure 1: Geometry of backboard and rim modeled in Abaqus/CAE

Dimensions:

Backboard:

72 in length x 42 in width x ½ in thick

Basketball rim:

18 in diameter, 5/8 in diameter rod (inside diameter is 6 inches away from backboard)

Mounting plate:

4 bolt pattern (5” x 5”)

3

Step 2:

Once the basketball rim and backboard assembly were finalized, the appropriate material

properties, boundary conditions, mesh and loads are applied to the model. A rough

model was used as a proof of concept using a coarse mesh while exploring the most

accurate and appropriate boundary conditions and constraints.

Step 3:

After the proof of concept study was completed, a suitable mesh was chosen for the

assembly. The material properties for the first model were of tempered glass (see Table

1 of Section 1.2). After appropriate boundary conditions and constraints were applied,

the load specified in Section 1.2 was applied on the rim. Once the load case is run, stress

and deflection data in the post processing menus are used to interpret how the backboard

reacts to the given load. After using the tempered glass material properties, the analysis

will be repeated two more times for the materials of interest shown in Section 1.2.

2.2 Finite Element Development Model

2.2.1

Two Part Backboard and Constraints

The finite element model of the basketball backboard and rim assembly was developed

consisting of 3 parts with 2 of the parts consisting of sections of the backboard. The

section that consists of a majority of the backboard was created as a 3D deformable

shell. The smaller section of the backboard was created as a 3D deformable solid. Each

section of the backboard had a thickness of 1/2 an inch thick with total dimensions as

specified in Section 2.1. A shell-to-solid coupling was used at the edges where the two

backboard sections meet (see Figure 2).

Figure 2: Backboard sections and highlighted shell-to-solid coupling

4

2.2.2

Backboard and Rim Constraints

The rim was created as a 3D deformable solid based on the geometry shown in Figure 1.

The part consists of a circular ring with a mounting bracket with a shape similar to an L

bracket. The mounting bracket has a 4 bolt pattern as described in Section 2.1. The bolt

pattern holes were created on both the mounting bracket of the rim and section 2 of the

backboard (see Figure 3).

Figure 3: Bolt pattern of rim and backboard with constraints highlighted (orange)

Reference points were created at the center of each hole diameter and depth. Rigid body

tie constraints were used to tie the surfaces (highlighted in Figure 3) to the reference

points to simulate where a nut and washer would fix the mounting bracket to the

backboard with a threaded pin.

A contact relationship was also created between the backboard and rim. This is to

ensure a more accurate simulation of the stresses transferred from the rim to the

backboard. The mounting bracket and section 2 of the backboard both consist of similar

meshes.

2.2.3

Boundary Conditions and Load

The boundary conditions for the backboard and rim assembly were created to simulate

previous backboard designs in which the backboard is fixed at its edges by an aluminum

frame that mounted to the structural frame and arms of the backboard stand. The

backboard was encastred at all four edges. The load was applied to a reference point

created at the point of the rim furthest from the backboard and a load of 325 lbf was

applied in the negative y-direction as shown in Figure 4.

5

Figure 4: Boundary Conditions and Load

6

3. Results and Discussion

Results of the finite element analysis of the tempered glass backboard are as follows.

The backboard experiences a maximum Von Mises stress of approximately 9000 psi

under the given load. The maximum deflection of the backboard in the z-direction was

approximately 0.0456 in.

Figure 5: Von Mises Stresses on Tempered Glass Backboard

Figure 6: Displacement in the z-direction of the Tempered Glass Backboard

7

4. Conclusion

8

5. References

1. "Basketball (ball)" Wikipedia: The Free Encyclopedia. Wikimedia Foundation, Inc. 2

July 2012. Web. 4 Jul. 2012. <http://en.wikipedia.org/wiki/Basketball_(ball)>

2. "Shaquille O’Neal." Wikipedia: The Free Encyclopedia. Wikimedia Foundation, Inc.

22 June 2012. Web. 4 Jul. 2012. < http://en.wikipedia.org/wiki/

Shaquille_O%27Neal>

3. Abaqus/CAE 6.10EF-1. “Abaqus User Manual.” Dassault Systèmes, Providence,

RI, 2010.

4. http://www.precisionglass.com/tech/gp.pdf

5. http://www.kaysons.in/acrylic/physicalproperties.pdf

6. http://www.efunda.com/materials/alloys/alloy_home/steels_properties.c

fm

9