Team X 1 Index Card Project Team X: Sarah Brothers, Margretta

advertisement

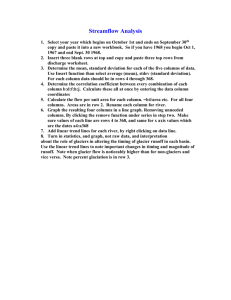

Team X 1 Index Card Project Team X: Sarah Brothers, Margretta Karousis, Mike Kovach, Dominic Rosace, William Urban Team X 2 Introduction Purpose The purpose of this report is to document the design process and testing of an index card structure conducted by Team X. Problem The assignment was to build a structure that held an optimum amount of weight in comparison to cost. The materials and costs consisted of ·3x5 inch Index Cards=$1.00 each ·Folds=$0.50 each ·Staples=$0.75 each Cost could be calculated by the equation: Where: ·c=total cost ·i=quantity of index cards ·f=quantity of folds ·s=quantity of staples Scope The requirements imposed on this project were: ·the structure had to be at least 1½ inches tall ·all components had to be in contact with each other ·index cards had to be placed on an edge ·all folds had to be a full crease, no curves ·the structure had to hold at least 2 bricks ·index cards could not be torn or cut Background Initial research indicated to Team X that triangles are one of the strongest geometric figures and that columns efficiently carry a heavy load to a foundation. Based on Euler’s formula for a pinned column, it was noted by the group that maximum weight would be supported by a column with the shortest unsupported length. The smaller the sides of the column are the closer it resembles a cylindrical column, which would be the strongest. Center of gravity also plays a part in the stability of a structure. The lower the center of gravity, the more stable the design will be. Therefore, the project should be the minimum allowed height. Finally, to ensure the maximum load, the columns should have the weight evenly distributed. This will help prevent premature failure of a single column which would lead to a total failure of the structure. Test and Evaluation Apparatus The primary basis of the structure consisted of 4 triangular pillars. These components were made by folding an index card hot dog style, then proceeding to fold it hamburger style twice, the remaining was then folded into thirds to create a triangular pillar. These pillars were connected by an X shape, created by stapling two index cards folded hot dog style at a fold in the Team X 3 center of each. (Figure 1 & 2) This device consisted of 6 index cards, 5 staples, and 24 folds; the final cost was $21.75. Procedure Team X met four times to develop their index card structure: September 11th, 12th, 18th, and 19th, 2007. The first meeting was spent brainstorming ideas on paper. During the second meeting they tested several structures, focusing primarily on small shapes. Among the shapes tested were triangles, hexagons, diamonds, and rectangles. The triangle proved to be the most efficient and versatile. They discovered a feasible design during their third meeting, and they perfected this structure during their final meeting. They performed many tests of each idea, most buckled due to imbalance. They tested their structures by placing a square board over the apparatus and stacking bricks on the board in layers of eight. (Figure 3 & 4) The structure held 28 bricks before it finally collapsed due to imbalance. (Figure 5) Findings In developing their structure Group X tested small components of structures rather than large designs, they did this because they found the summation of several weak components to be equally as weak as the individual parts. They also found the more balanced a structure is the less likely it is to fail; for this reason they placed the strongest parts of their structure, the pillars, on the outermost edges. Conclusion Assessment Group X completed the index card project by creating a structure that cost $21.75 and reached 129% efficiency. They believe their structure to be more than a success. This opinion is based on the equation: Where: P=Total Competition Points b=number of bricks supported c=cost of structure According to this equation Group X earned 129 competition points and thus achieved 129% efficiency. Recommendation Group X recommends additional modification to their design to further improve performance. This can be achieved by developing larger columns in a similar format, and placing these columns further apart. References “Columns: Inelastic Buckling.” Efunda. 20 September 2007 < http://www.efunda.com/ formulae/solid_mechanics/columns/inelastic.cfm>. Dieter, George. Engineering Design. New York: McGraw-Hill Inc., 1991. Team X 4 “Ideal Pinned Column Buckling Equation and Calculation, Euler’s Formula.” Engineers Edge. 20 September 2007 <http://www.engineersedge.com/column_buckling/ column_ideal.htm>. Team X 5 Appendix Figure 2: The Structure Figure 3: Strategic Stacking Figure 4: The Stack Team X 6 Figure 5: Failure!!