SolidWorks 2004/11 Interface Documentation

advertisement

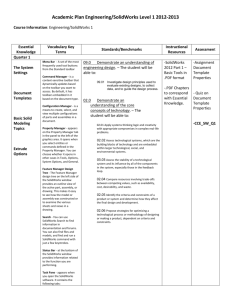

PDM9000 v8.7 – SolidWorks Interface User guide This description covers PDM9000v8.7 extension regarding cooperation with SolidWorks. Interface requires minimum SolidWorks 2004. This guide covers basic installation; implementations at customer side may vary. Because this guide is an extension to standard PDM9000 User Guide, some trivial subjects are covered very shortly. 1. STANDARD OPERATIONS ........................................................................................... 2 2. WORKING WITH PARTS ............................................................................................... 5 3. PART’S CONFIGURATIONS ......................................................................................... 7 4. WORKING WITH ASSEMBLIES .................................................................................... 8 5. WORKING WITH DRAFTS .......................................................................................... 18 6. WORKING WITH PARTSLIST ..................................................................................... 18 7. TOOLS MENU .............................................................................................................. 20 8. PICTOGRAMS.............................................................................................................. 21 9. VIEWING DRAWINGS ................................................................................................. 22 10. PLOTTING/CONVERTING DRAWINGS ...................................................................... 23 11. TECH - INTERFACE OVERVIEW ................................................................................ 24 12. TECH - PARTSLIST ANALYZE ................................................................................... 26 13. TECH - XREF OPERATIONS ....................................................................................... 27 14. PLOT DEVICES CONFIGURATION ............................................................................ 28 PDM9000 v8.7 – SolidWorks interface description 1 1. Standard operations SolidWorks drawings are registered in PDM with different file format codes: Parts and Assemblies should be registered like 3D Models and without paper format. System will preset these values when user sets proper file format. Opening is realized by standard PDM functions like for any other drawings. To open a drawing, user should use a function “Check out + Open”. This function first checks user rights for actual drawing. If all is ok, drawing is downloaded from central server into local station. After successful download, drawing is loaded into SolidWorks environment. PDM9000 v8.7 – SolidWorks interface description 2 After opening, PDM sets drawing’s properties, which are filled with info from database. SolidWorks standard properties. PDM9000 v8.7 – SolidWorks interface description 3 SolidWorks custom properties. Standard properties are fixed, custom properties are configurable in PDM configuration tables. Custom properties are later used for composing Partslist definition template. User is free now to design a drawing. When drawing is ready and need to be saved, user should switch to PDM and use function “Close + Check in”. Closing drawing performs drawing structure analyze and save a local copy of the file. Check In operation, transfers local drawing to the server. It is recommended to perform “Save” operation in SolidWorks first. This will discover or prevent any geometry conflict situation which may occurs in SolidWorks. Opening in ReadOnly mode. Read-Only mode do not belongs to Open operation but to RENT operation. Drawing rented in Read-Only mode is stored on local drive with RO file attribute so after opening in SolidWorks, this attribute is labeled on caption line. PDM9000 v8.7 – SolidWorks interface description 4 2. Working with Parts Parts are most simply models in SolidWorks. Because of file properties, every part registered in PDM should be open and save by PDM minimum once. During opening, part object becomes his number and description which is later used in Assemblies and Drafts. During saving Part or Assembly, PDM asks for Configuration, material and physical mass of model. This information is stored in variants table. PDM9000 v8.7 – SolidWorks interface description 5 PDM9000 v8.7 – SolidWorks interface description 6 3. Part’s Configurations SolidWorks uses Configurations. PDM supports this feature on Variants level. Variant code must correspond to Configuration Name in SolidWorks. Master Variant ($) always corresponds to Default configuration. PDM supports Configurations in following operations: Open; during opening, configuration is set to actually selected variant. Custom properties set; variables with “VARIANT.” prefix will be created for specific Configuration only. Place; during placing part on assembly, PDM sets actually selected variant (if not selected, SW uses last active Configuration saved in Part) Save: during structure analyse, PDM scans physical properties and store it in Variant table. Because of speed, only actual variant/configuration is processed. To perform complete set of variants, dedicated function in Tools menu is available. PDM9000 v8.7 – SolidWorks interface description 7 4. Working with Assemblies During opening every assembly, system checks if there are some referenced drawings (in Autocad syntax called Xrefs). If they are, system displays additional panel with a list of all additional files which need to be downloaded locally before main drawing can be open. List contains some special information. Except drawing number, revision, name etc. there is information about user which actually rents drawing (this mean: blocking). If there are some important info, they is marked in Comments. User may choose to download a drawing in full mode or just take a read-only copy. This is defined by left checkbox. Like a default, all checkboxes are on or off, it depends of global system settings. Additionally, some drawings may be highlighted with different colors. Color red means so drawing is blocked by other user or his status. Such drawing can not be rented in full mode. Color green, mean so there is some additional remark for user. Example is a new revision of detail drawing used on assembly. Before main drawing can be open, system performs download of all used components. Components rented in full mode may be edited „in place“ in SolidWorks. Components rented for read-only, gets a read-only attribute on local drive and can not be modified nor check in to the server. Parts Placing/ Replacing module If you want to place a part on assembly or on draft, you have to call part placing function from Toolbar or Tools menu. System will present following panel: PDM9000 v8.7 – SolidWorks interface description 8 This panel has 6 sections. Section 1. You may choose which drawing you want to place. Like a default, system enables actual drawing option (it simulates old style working style). System remembers last placed drawing and presents it in second option. Last option is activated when we wants to place other drawing, selected from list below. Section 2. This is a filter and result window. When we want to place other drawing then actual we have to find it. In search box we may put drawing number or name. Remember about asterix characters. Search result window presents drawing number, revision, page, name and type. This, of course may be customized. Section 3. This section is just a more detailed information about drawing. Actual or selected from a list. Field Status is a clever field, when drawing is in status Approved, information is presented in GREEN color, status Cancelled is RED, all other statuses are DARK GREY. This is not only information. Status has impact on option Rent Mode from section 4. Only GRAY statuses may be rented in RW mode. For colored statuses, this option is disabled and set to RO mode. Section 4. Revision status tells if drawing revision from section 3 is the last one. If not, system presents RED information. Next field presents file status reported by the server. Drawing from section 3 may be free (not rented by any user), may be rented by actual or other user. Depends of situation, Rent Mode option may be blocked. Rent Mode option allows to choose in which mode drawing will be rented from server. Default option is RO. This option may be blocked by other fields like Status, Revision and Server File state. Local file state informs us about local copy of drawing file. System checks if such copy exists and if is actual. System compares timestamp with server copy. If we posses valid copy of a file, download operation will be skipped and system will use our local copy. At any other situation, system will try to download fresh copy of a file. Section 5. PDM9000 v8.7 – SolidWorks interface description 9 This section allows us to choose work mode. We may just place a part on assembly or replace existing reference (old link for replacement should be selected in CAD system in the background). For Inventor exists specific placement mode for Derived parts. Work Mode switch accelerates separate function from old version into one, powerful panel. Section 6. This section presents Pictogram miniature if such one exists. Creating InPlace Components During Top-Down designing, user creates new components via SolidWorks “New Part/Assembly” function. For PDM it is important to create such elements in PDM Local Directory. All components created out of this directory will be ignored during structure analyze. It is also important to use unique filenames. If file name has a conflict with already registered drawing, system will block such registration. During saving Assembly, PDM performs structure scan. All known drawings are registered like XRef links. New created drawings, which are unknown to PDM need to be registered. For every such model, PDM exposes registration dialog. PDM9000 v8.7 – SolidWorks interface description 10 To prevent future problems, temporary used filename (Part1.SLDPRT) should be exchanged by standard PDM file naming convention. “Rename Local File” button allows to make such operation. PDM will generated proper filename corresponding to drawing number and then physically rename file on disk and also replace link in assembly. After InPlace registration, every drawing should be open and save once. That was mentioned in previous chapter. This operation sets drawing properties which are important in later drawing and partlist management. If user will not do this operation, SolidWorks will use model filename. Opening and save operation is specially important for SubAssemblies. PDM always scan only one level structure (for unknown elements). If user creates multilevel structures in InPlace technik, every subassembly must be load and save separately. During closing, drawing is analyzed and all known XRef links are transferred into central database. Such elements are accessed via standard drawing items (master variant $), with code „XRef“. PDM9000 v8.7 – SolidWorks interface description 11 Refreshing expired links During constructing assembles some parts may become new revisions, other may be duplicated. It may be necessary to exchange expired parts with new versions or completely replace old parts by new one. User has two possibilities to realize this operation. First way is to replace parts manually. After loading assembly, user must select one or more parts in SolidWorks, switch to PDM, find part to replace and use “Replace component” function. This operation will replace all selected (in SolidWorks) components by actual, PDM drawing. This function may be used for new revision or for quite different parts. Second way is a function “Actualize links”. This function may/should be called any time from Tools menu or during opening Assembly. System reminds to use it after running functions: “New revision”, “Copy drawing” and “Replace drawing” if this is 3D drawing with Draft or any 3D drawing with master links. Below is described scenario with new revision. Let say, we have project with some Parts and Assembly. One of the parts (Logo) has Draft like a second page. PDM9000 v8.7 – SolidWorks interface description 12 We will make new revision of our Z2005-00247. After generating new revision of Logo drawing, PDM recognize so there are some Master drawings which points to old model. In this situation it will be Draft from Page2 and Assembly Z2005-00118. PDM displays info message: Similar information is display during open of every Master drawing (assembly sample): All links corrections should be made on local station using original CAD system, main drawing should be rented in RW mode. We have now two operations to do: 1. Move assembly Z2005-00118#0 link from Z2005-00118#0#1 to Z2005-00118#1#1 2. Move Draft Z2005-00118#1#1 link from Z2005-00118#0#1 to Z2005-00118#1#1 PDM9000 v8.7 – SolidWorks interface description 13 First operation: we step on assembly and call Actualize Links from Tools menu: System performs data scan and prompts necessary corrections. User has also option to correct existing data by choosing other drawings, just click on links arrows: After selecting proper drawings and mark selected links, PDM will download all necessary components and physically change links in assembly. Links are also corrected in database. Assembly should be returned to the server. The same procedure should be made for second page Draft. Working in “Lightweight” mode SolidWorks has special feature to load assembly’s subcomponents in lightweight mode (simplified) which speedups working with large assemblies (This is not a default set after standard installation). PDM9000 v8.7 – SolidWorks interface description 14 Unfortunately we discover internal error by structure reporting in this mode. Officially, SolidWorks accepts 2 types of file extensions: 3 letters (PRT, DRW, ASM) and 6 letters (SLDPRT, SLDDRW, SLDASM). In theory and documentation, both extensions works equal. In practice, lightweight mode produces errors working with 3 letters file extension. Because of this, PDM need to be configured for 6 letters. This should be made in WWW_PROGRAMS table. In PDM9000 versions >8.50, this is a standard. PDM9000 v8.7 – SolidWorks interface description 15 Assembly browser – display name modification When working with assembly we would like to see PDM drawing number instead of physical filenames. There is a trick to do that. At first we have to define a variable/property in PDM configuration, which has to be display later in SW. Now, every model loaded into SW from PDM will become this custom property. Now we have to set up SW configuration. Goto Tools/Options/General and change description for tree display. Last step is to change Tree display mode for assembly browser. Open any assembly, step on the root node, right-mouse-button and set all options like below: PDM9000 v8.7 – SolidWorks interface description 16 Now, whenever possible, SW will display our CAPTION property in structure browser. PDM9000 v8.7 – SolidWorks interface description 17 5. Working with Drafts SolidWorks use titleblock technik. All custom specific borders and titleblocks are defined like Resources inside draft template. They are recognized by names. PDM set proper border and titleblock follow configuration definition. Titleblocks are filled by drawing properties which are set during drawing opening. Drafts may be registered in PDM like independent drawings or like Assemblies/Parts views. Independent drafts are registered with new drawing number. On such drafts, user may place many models. Drafts which are views for one model are registered like a second page. This operation is realized by function “Create factory drawing” available from Tools menu. It will generate second page of actual drawing. This drawing will become “Draft” type. It should be loaded into SolidWorks. After loading, user should place first page View by SolidWorks function “Model View”. After saving second page, system will register link between first and second page. Operation “Change Status” will change status for both pages at once. More work is necessary during generating new revision from Part which have second page with Draft view. Because system can not automatically correct physical link in the draft, user must load second page and use function “Actualize Links”. This function will discover new revision of the model and replace link for a new one. 6. Working with Partslist SolidWorks partslist is analyzed during saving draft drawing. At first, partlist must be created on draft drawing. If partslist exist, PDM transfers contents into database. PDM9000 v8.7 – SolidWorks interface description 18 All partslist positions are stored in a central database and can be accessed via object manager. If partslist object is unwanted on Draft drawing, user should shift it outside paper space. This will keep partslist object but will not be printed. After transferring partslist to main server, system exposes different kinds of partslist. They are accessed via REPORTS system menu. PDM9000 v8.7 – SolidWorks interface description 19 7. Tools menu Tools menu is a special panel for controlling functions designed for actual drawing type (or application). For Solid Works files, following functions are available: Part list analysis + Save – perform partslist/XRef analyze and saves drawing. Final, drawing stays in SW for future corrections. Structured Return – performs structure analyse and allows to return all rented subcomponents. Configuration + Save – perform configurations analyse and stores result in variants table. Actualize links – function search for subdrawings with newer versions and then updates all links to actual ones. Place as Model – places/replaces actual PDM drawing on active Assembly or Draft. Placing on Assembly may be done in derived mode. This option is active for Parts and Assemblies only. Create Factory Drawing – creates second page of actual drawing. Filename is created from actual drawing with suffix “_WZ”. This option is active for Parts and Assemblies only. Copy structure with template – function duplicates full 3D structure with new drawing numbers. Copy Norms Localy – copy all registered XSTD elements on local drive. Important for offline working. . PDM9000 v8.7 – SolidWorks interface description 20 8. Pictograms Pictogram Server, part of PDM installation, can produce proper bitmaps for all SolidWorks types of files. Detailed description is covered by separate guide. Later, pictogram’s gallery may be presented. PDM9000 v8.7 – SolidWorks interface description 21 9. Viewing drawings View of a drawing is possible in two ways. First one is to use standard SSV generator. SSV will transform SolidWorks native format into GIF file and display it in new window. This view is used for initial perspective. It is fast and independent of user configuration. It works always under Internet Explorer even if user has no SolidWorks installed. SSV expose additional filters like TIF, PDF, VRML, SAT, IGES, STEP and eDrawings (EPRT, EASM, EDRW). Result of using these filters may vary. SSV always translate SolidWorks drawings into desired format but local station MUST have installed Internet Explorer Plug In to properly view such file format. PlugIns are not a part PDM9000 installation, they must be purchased by independent vendors. TIF format may be viewed by standard Windows Imaging. eDrawings format is supported by SolidWorks eDrawings Viewer. SAT format may be view by Spatial SAT viewer. Second way to view the drawing is a classic download and view in dedicated viewer defined in system configuration. In this mode, native SolidWorks file is viewed, system do not perform any transformation for the file. PDM9000 v8.7 – SolidWorks interface description 22 10. Plotting/Converting drawings Plotting is realized by PDM9000 plot station. Plotstation sends request to SSV server which physically perform plot operation. At first, plot operation is activated by PLOT button placed on variants list. Now, drawing is placed on a Plotstation list. User should choose desired plotter device, format etc. Some drawings may be in status different then „APPROVED“, such drawings are by default not marked for plotting, user should mark them manually. Function PLOT, plots all marked drawings. Plotstation panel also supports two additional operations: Convert & Export. Export operation just exports original files into WWWEXPORT directory. Convert operation may convert bunch of drawings into desired format (supported by SSV). PDM9000 v8.7 – SolidWorks interface description 23 PDM9000 – SolidWorks Interface Technical description 11. TECH - Interface Overview PDM9000 SolidWorks interface bases on OLE Automation technology. Interface consists from two parts. First, CAD common part resides on the server and delivers data via standard ASP/HTML pages. Second part is coded inside local component installed on every user station. Drawing properties and titleblocks During opening every drawing, PDM set some standard drawing properties follow the information from a form. These properties are: swSumInfoSubject swSumInfoTitle swSumInfoAuthor swSumInfoKeywords - Project, Drawing, Revision and Page number - Benennung1 - User Full name - PDM9000, Project, Drawing and Benennung1 Additional, Custom properties are set follow current configuration defined in WWW_PROGRAMS_TEMP table. Properties with prefix “VARIANT.” are send to Configuration specific pool. [Variable Conversions] VARIANT.IDNR=”%F VAR_IDNR%%” ZEICHNR="%F ZEICHNR%%" ANDR="%F ANDR%%" FRG="%F FRG_DICT%%" ; PDM sets a proper border and titleblock and fill it with values from a form. SolidWorks borders and titleblocks are defined in table WWW_LOGO_FORMAT. Description of used columns: swPaperSize - predefined, physical paper sizes used by SolidWorks swTemplateIn - predefined, physical background templates used by SolidWorks swTemplateName - name of the user template swPaperSizeCustomX - Paper width if swPaperSize = swDwgPapersUserDefined (12) or swTemplateIn = swDwgTemplateNone (13) swPaperSizeCustomY - Paper height if swPaperSize = swDwgPapersUserDefined (12) or swTemplateIn = swDwgTemplateNone (13) Values for fields swPaperSize and swTeplateIn are taken from SolidWorks API description. Such description is delivered with standard SolidWorks installation. For field swTeplateIn PDM9000 v8.7 – SolidWorks interface description 24 PDM interface typically uses value 12, which means: UserDefinedTemplate. You can see it in the template definition on the Draft drawing. Fields swPaperSizeCustomX/Y should be used in two situations: when non-standard paper size is used (swPaperSize =12) or when no titleblock is used (swTeplateIn =13). Values should be set in millimeters. PDM9000 v8.7 – SolidWorks interface description 25 Materials PDM9000 operates with table ARCHIV_MATERIALS where all materials and their CAD codes are stored. For SolidWorks there are fields SW_MATERIAL & SW_DENSITY. Both values are set during opening drawing or by Reloading Variants. Like a default, PDM set SW material name stored in standard “Solidworks materials” table. IF you want to use other SolidWorks material table (private materials) then, name of this SolidWorks material table should be specified in field SW_MATTABNAME. 12. TECH - Partslist analyze Local configuration file LTE9000.INI may contain following variables which controls SolidWorks interface. [LTEICSettings] SW_3DANALYSE=1 SW_STCLANALYSE=1 SW_MASSANALYSE=1 SW_STLVAR=ITEM ITEM:POSNR;QTY.:QUANTITY;PART NUMBER:ZEICHNR1;REV:ANDR1; SW_FASTENERSLIBDIR=F:\DATA\NORMS SW_FASTENERIDNR=IDNR SW_ADDIN_1=C:\Program Files\Bluebeam Software\Pushbutton PDF\SolidworksLt\BbSldWksPdfLt.dll SW_ADDIN_2=C:\Program Files\Common Files\eDrawings2006\SWPublisher\EModelSolidWorksu.dll SW_3DANALYSE (0/1) switch on or off 3D structure analyze for assemblies, derived parts and drafts SW_MASSANALYSE (0/1) switch on or off physical properties for parts and assemblies. Following model properties are retrieved: MASS, VOLUME, AREA, MATT SW_STLANALYSE set to 0, switch off completely every structure or partlist scan. SW_STLVAR is responsible for translating partlist columns into PDM database fields. Syntax is as follow: SW_COLUMNLABEL:PDMFIELD; SW_DEFAULTCONFIGNAME – optional value. Default Configuration in SW is called “Default”. IF in any reason, your SW will name it differently (national version?) you may redefine it here. SW_DEFAULTSHEETNAME – optional value. Default sheet name in Drafts is called “Sheet”. IF in any reason, your SW will name it differently (national version, Blatt?) you may redefine it here. SW_FASTENERSLIBDIR, directory which should be treated like a StandardParts pool and not registered in PDM. SW_FASTENERIDNR, custom property name which holds article number (IDNR) in StandardParts. SW_ADDIN_x – list off AddIn files which should be loaded after SW starts in OLE mode. When SW is started from desctop icon, they are loaded automaticaly. Important for PDF or TrackBall drivers. PDM9000 v8.7 – SolidWorks interface description 26 13. TECH - XRef Operations Default download mode is controlled by system variable XREFSRENTMODE. It may be set to IW = Read-Write/IR = Read-Only. This variable may be also defined for specific file type controlled by file extension. For example, default switch for SolidWorks Assembles should be defined in variable : XREFSRENTMODE.IAM System variable LOCALFILESNEEDSRW, for default is set to “.SLDPRT;.SLDASM;”, this means so all SW Assemblies and Parts are locally with RW dos attribute even if they are rented in RO mode. It is necessary because Configuration technology used by SW need to write data into local files. Of course, files rented in RO mode (Approved) can not be check-in back to the server. Using SolidWorks on SSV and/or Pictogram Server machines do not forget to install LTE SolidWorks Event’s Monitor Tool. This small program will solve problems with links pointing to C:\Program Files\LTE9700\WWWOPEN. Such links will be resolved via database. PDM9000 v8.7 – SolidWorks interface description 27 14. Plot devices configuration Plot devices are configured in table ARCHIV_PLOT_DEVICELIST stored in main database. Except standard settings described in PDM Plot documentation, there are some special settings for SolidWorks: Field ADDITIONALCOORDINATES may store additional keywords: * SWSCALETOFIT 0 – SW PageSetup.ScaleToFit parameter is OFF 1 – (default value) SW PageSetup.ScaleToFit parameter is ON Sample: |SWSCALETOFIT=1| Keyword is OPTIONAL. * SWPAPERSIZE PaperSize number specific for actual printing device. Sample |SWPAPERSIZE=66| Custome paper size defined by exact values. Sample: |SWPAPERSIZE=Custom; X=2500;Y=2000| Remark: Length is in 0.1mm units. To define a paper that is 250mm long, set X to 2500. Keyword is OPTIONAL. * SWPAPERSOURCE Paper source number specific for actual printing device. Sample: |SWPAPERSOURCE=45| Keyword is OPTIONAL. When these keywords are missing, system uses standard papersize codes defined by SolidWorks API. They works quite ok for typical formats alike A4 or A3. With some specific devices (like large format plotters) it may be necessary to define exact values corresponding to device driver. Please, use our testing tool from CD, which detects actual paper formats. Device names in fields SSVDEVICENAME & SSVDEVICESHARE are case sensitive. Field PLOTRESIZE should contains rotation parameter for models (they have no format). So there should be definition …! FF 0 L ! … (for Landscape printing) Field PLOTFORMAT accepts only following codes which has corresponding values in SW API: A0, A1, A2, A3 A4, A4V, A4H, A, AV, AH. If other values are used, please define SWPAPERSIZE parameter. PDM9000 v8.7 – SolidWorks interface description 28 Mysłowice 25.10.2004 Last correction: 07.09.2007 Adam Wieczorek LOGOTEC Engineering S.A. PDM Research Department PDM9000 v8.7 – SolidWorks interface description 29