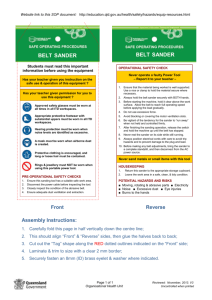

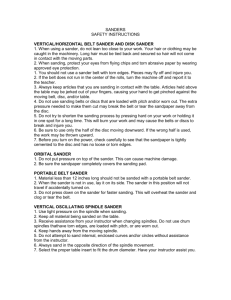

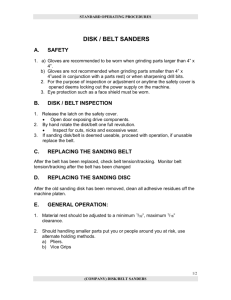

Stationary Sander Safety

advertisement

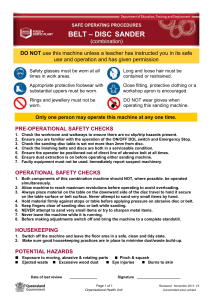

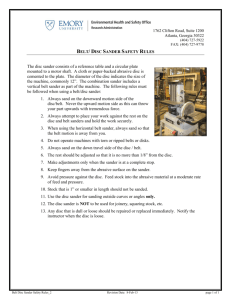

Stationary Sander Safety ( Disk / Belt / Edge / Oscillating) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Follow Shop Safety Rules. Sand on down side of the disc (the disk would rotate downwards) therefore forcing the stock down against the table and holding the wood in place. Keep material moving and sand lightly, a sanding disc or belt in good condition requires little pressure. Pushing too hard against the disk or belt may cause an operator’s hand to slip and press into the disk / belt which can lead to injury. ALWAYS use the table to support the material. Always use clamps or jigs to hold small pieces. Small pieces can be jerked out of an operator’s hand easily, which could lead to injury. Ensure the abrasive disc is secured and centred as closely as possible. Keep fingers / hands a minimum of 2 inches from the sanding surface. NEVER put a finger or hand between the disc or belt and the table. The sander can pull a finger in quickly and literally sand it off. NEVER sand the face of thin materials. Only the instructor will make adjustments or changes the abrasive discs / belts. ALWAYS sand to a line and stop when you get to it. Do not leave a sander until it has come to a COMPLETE STOP. Key Points ! Sand on down side of disk. The disk rotates downward forcing the stock down against the table. ! Pushing too hard against the disc or belt may cause an operator’s hand to slip ! Use clamps or jigs to hold small pieces ! NEVER put a finger or hand between the disc or belt and the table ! NEVER use your hand to remove dust from the table, use a brush