caSe Study: reSponding to

cuStomer reQueStS for a recycling

Solution for vaccine containerS

challenge

Each year, Merck uses more than 1 million white Styrofoam™

shipping containers to fill vaccine orders placed by doctors,

pharmacies and hospitals across the United States. But until

Merck initiated a new environmental program in 2010, recipients

had no easy way to recycle these containers — and that’s just

what many wanted to do. Merck set out to find a customerfriendly and cost-effective way for its customers to recycle the

company’s vaccine shipping containers that would not compromise the containers’ ability to maintain required low temperatures

during storage and delivery. As one Merck team member

explained: “Our products need to get where they are supposed

to go at the temperature they need to be — all the time.”

BacKground

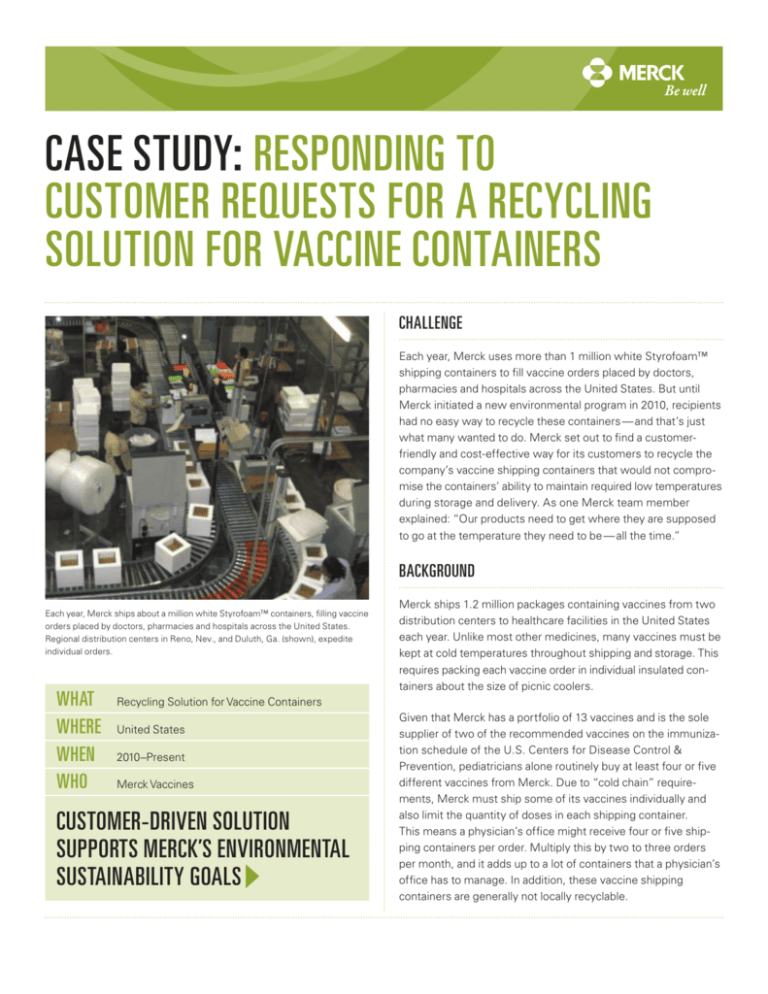

Each year, Merck ships about a million white Styrofoam™ containers, filling vaccine

orders placed by doctors, pharmacies and hospitals across the United States.

Regional distribution centers in Reno, Nev., and Duluth, Ga. (shown), expedite

individual orders.

what

where

when

who

Merck ships 1.2 million packages containing vaccines from two

distribution centers to healthcare facilities in the United States

each year. Unlike most other medicines, many vaccines must be

kept at cold temperatures throughout shipping and storage. This

requires packing each vaccine order in individual insulated containers about the size of picnic coolers.

Recycling Solution for Vaccine Containers

United States

2010–Present

Merck Vaccines

cuStomer-driven Solution

SupportS mercK’S environmental

SuStainaBility goalS

Given that Merck has a portfolio of 13 vaccines and is the sole

supplier of two of the recommended vaccines on the immunization schedule of the U.S. Centers for Disease Control &

Prevention, pediatricians alone routinely buy at least four or five

different vaccines from Merck. Due to “cold chain” requirements, Merck must ship some of its vaccines individually and

also limit the quantity of doses in each shipping container.

This means a physician’s office might receive four or five shipping containers per order. Multiply this by two to three orders

per month, and it adds up to a lot of containers that a physician’s

office has to manage. In addition, these vaccine shipping

containers are generally not locally recyclable.

“We definitely heard the strong voice

of customers telling us that it was

important to them to find a way to

recycle these containers.”

Lois Burkey, Merck Vaccines team, West Point, Pennsylvania

Solution: facilitating customerfriendly, cost-effective recycling

of empty shipping containers

In 2008, Merck launched its new Commercial Model, an initiative that places customers at the center of our work. Customers

had been demanding more from companies and new types of

relationships, requiring Merck to change how it marketed and

sold its medicines and vaccines. As part of this new approach,

Merck’s Vaccine Division (MVD) created a Customer Feedback &

Response team tasked with speaking with customers to understand their needs, challenges and desires related to how we

conducted business with them, and integrating their findings

throughout Merck decision-making.

One resounding customer comment was that receiving and then

having to discard so many vaccine containers was a nuisance.

Some healthcare facilities, particularly in the Northwest, actually

went to the trouble of seeking out local recycling centers and

taking them there themselves. It was clear that today’s customers expected Merck to be environmentally responsible and to

help its customers be so as well.

Joined by colleagues from Merck’s Global Procurement group,

the MVD Feedback & Response team faced many questions:

• How many customers would use a recycling program?

• How much would it cost?

• C

ould Merck sustain the cost of the program, especially

if participation continued to grow?

• W

ould the containers be returned contaminated with

used needles, empty vaccine vials, or other waste?

The team knew it wanted to create a process similar to that of

recycling printer cartridges. And, of course, the process had to

be very easy for customers.

In 2009, the team began a five-state pilot program. Here’s how

it worked: A physician’s office, pharmacy or hospital ordered

vaccines directly from Merck. Merck shipped the vaccines in

their special containers. Each container included instructions on

how to recycle the container (e.g., empty the container before

shipping) printed on an adhesive material that served as packing

tape to seal the container upon returning it. Also included was a

prepaid UPS shipping label. The containers were picked up by

UPS and sent to one of two Merck-identified recycling facilities.

The recycling facilities then turned the Styrofoam containers into

other materials such as insulation and building materials.

About 30 percent of the customers included in the pilot program

participated, with nearly no instances of needles or other refuse

being left inside the returned containers. The MVD team presented its results to management, estimating an annual program

cost of $2 million based on an uptake of 30 to 40 percent.

The team delivered its findings to MVD management. The

response from then-MVD President Margie McGlynn: If this is

what our customers want, then we will figure out how to

develop a national recycling program and what it would cost.

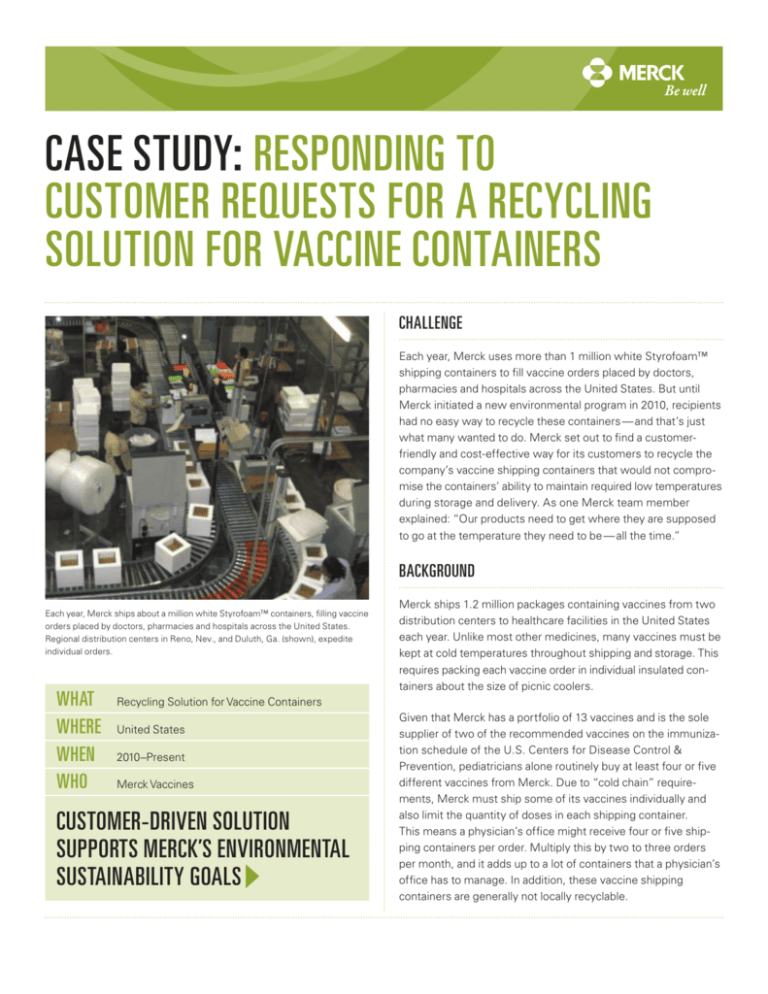

Individual orders — and proper coolants — are packed into insulated containers.

Unlike many other medicines, vaccines must be kept at cold temperatures

throughout shipping and storage.

The initiative was approved. “There wasn’t a lot of discussion or

challenge,” remembered Craig Kemp, Senior Director, Customer

Value, Merck Vaccines. “Senior management knew this was the

right thing to do, and they did it. It made me really proud to work

for the Company.”

In February 2010, Merck rolled out the container recycling program to its entire western U.S. territory. In late May 2010, the

eastern half of the country was added. By June, fully 20 percent

of the insulated Merck containers were being returned to

recycling facilities in Michigan and California. Today that number

stands at 40 percent (~20,000 containers), which prevents

40,000 lbs. of Styrofoam from being added to landfills or burned

in incinerators each year — an admirable result for a voluntary

recycling program in little more than one year’s time.

“We did this not only because it was

the right thing to do, but [also because]

it’s what our customers wanted. People

want to do business with a company

that is socially responsible.”

Craig Kemp, Senior Director, Customer Feedback & Response,

Merck Vaccines

“This program is responding to a customer demand. And it’s

helping to build trust and value with our customers,” says Kemp.

“We are doing more than selling a product; this program tells

our customers that Merck is part of their community and takes

its responsibility to the environment seriously.”

During a field visit to Arkansas just after the national launch

of the program, a Merck Field Sales Customer Team Leader

heard positive feedback from healthcare providers and staff.

“Customers stated multiple times that they are very happy

about Merck deciding to recycle.”

The recycling program is also important to many Merck

employees, who believe that companies have a responsibility

for environmental sustainability and want to work for a company

that demonstrates its commitment through action.

Such customer and employee satisfaction benefits, while

difficult to quantify, are critical to the program’s sustainability,

particularly given that the recycling program accounts for almost

10 percent of Merck’s annual vaccine shipping budget.

Another important factor is that the program supports Merck’s

corporate packaging goal, announced in 2011, which aims for

50 percent of Merck’s revenue to be derived by 2020 from the

sale of products that have at least one sustainable-packaging

attribute, such as attachment to a packaging take-back program.

what’s next?

Kemp and his team are now working with the Merck Packaging

Technology team and Merck’s vaccine shipping-container

manufacturer to create a vaccine shipping container using

recycled polystyrene. The containers, which need to be tested

to ensure that they perform to the same standard as the existing

containers and meet all regulatory requirements without a

significant increase in price, would, if successful, increase the

environmental benefits of Merck’s vaccine shipping-container

recycling program.

Another option Merck is exploring is making its containers

reusable. In this model, customers would send the shipping

containers back to a third party, who would then clean, test,

and return the containers to Merck to reuse in shipping vaccines

to other customers. Currently, the cost of making containers

reusable is significantly higher than that of recycling Styrofoam

containers, but Kemp believes it would pay for itself in time.

The challenge is setting up an innovative logistics system to

make it work, he says.

Merck is also looking at expanding the current recycling

program into other countries and to other products with cold

chain requirements.

“There has been very little — if any — innovation in medical

logistics; we’ve been shipping products the same way for

decades,” says Kemp. “Other industries have innovated and

created more efficiency in the process — we can now get fresh

fruit from South America in the winter, for example. This was

innovation. Now it’s our turn. This makes sense for our business

and for our customers.”

To learn more about Merck’s environmental

sustainability journey, click here.

Copyright © 2011 Merck Sharp & Dohme Corp., a subsidiary of Merck & Co., Inc. All rights reserved.