INFLUENCE OF THE MOLAR MASS OF UREA

advertisement

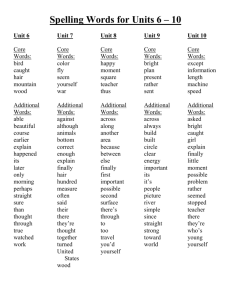

INFLUENCE OF THE MOLAR MASS OF UREA-FORMALDEHYDE ADHESIVES ON THE SHEAR STRENGTH OF ADHESIVE JOINTS Ivana Gavrilović-Grmuša1*, Manfred Dunky2, Jovan Miljković1 and Milanka DjiporovićMomčilović1 ivana.grmusa@sfb.rs 1 Faculty of Forestry, University of Belgrade, Kneza Višeslava 1, 11030 Belgrade, Serbia 2 Kronospan GmbH Lampertswalde, D-01561 Lampertswalde, Germany Abstract: The objectives of this study was the evaluation of the influence of the molar mass (degree of condensation) of urea-formaldehyde (UF) adhesives on the shear bond strength of wood joints. Radially and tangentially cut beech (Fagus Moesiaca) and fir (Abies Alba, Mill.) plies were bonded by hot pressing using three types of UF resins with different molar mass together with extender, hardener and safranin as coloring agent. The results show a significant correlation between the shear strength of the adhesive joints and the molar mass of the adhesives; bond strengths decrease with increase of the molar mass of the adhesives. As expected the shear strength of the adhesive joints was higher for beech compared to fir, based on the different wood strength itself and reflecting mainly wood failure. Shear strength of tangentially cut wood and hence showing radially penetration was higher than for radially cut surfaces, enabling tangential penetration; these results were the same for both wood species investigated and for all three applied adhesive mixes. Even the portion of wood failure was high, still different shear strength were observed due to a certain fortification effect of the interphase by the penetration of the adhesive. The higher the penetration, the thicker hence the interphase, the higher was the achieved shear strength. Key words: shear strength, beech (Fagus Moesiaca), silver fir (Abies alba Mill.), molar mass, degree of condensation, urea-formaldehyde (UF) adhesive, radially and tangentially cut wood 1 INTRODUCTION The use of condensation resins (Dunky, 2003; Dunky and Pizzi, 2003) for bonding wood components like veneers, particles, or fibres plays a dominant role in the wood based panels industry. Bond strength is determined (i) by wood related parameters (like density, strength of the wood tissue itself, or grain angle), (ii) by the properties of the resin and the adhesive mix (such as chemical structure like molar mass distribution, composition of the adhesive mix, viscosity, wettability on the wood surface, amount of adhesive spread, and hardening time and rate of resin curing), and (iii) by various bonding processing parameters (like assembly time, press temperature and pressure, or moisture level). 1463 The available bond strength also is influenced by the penetration behaviour of the adhesives into the wood surface; this penetration behaviour as such depends on the various parameters as already mentioned above. Low bond strengths will result from either underor over-penetration. When under-penetration occurs, the adhesive is not able to move into the wood substance enough in order to create a large active bonding surface (interface) within the interphase; in contrast to this, during over-penetration a big portion of the adhesive can penetrate into wood substance causing starved bond lines, with only insufficient amount of adhesive remaining in the bond line to bridge between the wood surfaces and to establish bond strength. The viscosity of the adhesive, hence, and especially its dependence from temperature in the bond line during the press cycle have to be adjusted by proper composition and molecular structure (size of the adhesive molecules, molar mass distribution, or degree of condensation) of the adhesive. This influence of the molecular structure on the depth and speed of penetration of the resin or the adhesive mix is still partly under investigation. Using UF resins with different degrees of condensation and hence different viscosities, Scheikl and Dunky (1996, 1998) showed that higher viscosities of UF resins decrease the penetration into the wood substance. Penetration into latewood with narrow lumens was slower than into earlywood with wider lumens. In earlier papers (Gavrilovic-Grmusa et al. 2010 a+b) the authors reported for the first time about the influence of the degree of condensation of a UF resin on the penetration into a wood surface; this study was performed using fir and beech as wood material, and in radial and tangential direction. The influence of the degree of condensation preferably is given during the application and the hardening reaction. Surprisingly only a very limited number of papers reported about the influence of the molar mass of UF resins on the achievable bond strength (Ferg et al., 1993; Pizzi, 1983; Rice, 1965; Nakarai and Watanabe, 1962). The intention of the work reported here was to evaluate a possible influence of different molar masses (different degrees of condensation) of UF resin on the achievable bond strength in wood joints. Main parameters in these investigations had been the used wood species (fir, beech) and the cutting direction (joining two tangential or two radial surfaces). For this purpose an UF lab batch was prepared and samples were taken after three different time spans during the condensation reaction, hence showing three different degrees of condensation. A higher degree of condensation means formation of greater molecules which then should differentiate in their penetration behaviour as well as the achieved bond strengths. 2 MATERIALS AND METHODS The samples used in these studies were the same as prepared for penetration investigations reported earlier (Gavrilovic-Grmusa et al. 2010 a+b). 1464 2.1 Wood raw material Beech and fir logs were cut from the trunks at the height of 1.3 m and with a length of 1100 mm. Boards of 42 mm thickness were cut using a band-saw. After initial air drying the boards were further dried in a laboratory kiln drier and planned to the final dimensions of 1000 mm * 150 mm * 30 mm. These boards were then cut into radial and tangential blocks of 100 mm * 30 mm * 5 mm in order to get tangential and radial surfaces to be bonded for the shear strength tests. The tangential cutting direction gives radial surfaces and radial penetration; the radial cutting direction enables the penetration into the tangential direction. These blocks then were conditioned at a relative air humidity of 65 ± 5% and a temperature of 20 ± 2oC. 2.2 Urea-formaldehyde (UF) resins Three UF resins with different degrees of condensation were provided by DUKOL Ostrava, s.r.o. (Ostrava, Czech Republic) as already reported earlier (Gavrilovic-Grmusa et al. 2010 b). The degree of condensation (DOC) increases with the duration of the acidic condensation step from resin UF I (lowest DOC) to resin UF III (highest DOC). The viscosity of the three resins increases due to the increasing size of the molecules presented in the resin from 218 mPa.s for UF I to 281 mPa.s for UF II, and, eventually, to 555 mPa.s for UF III. In order to keep the same gel time of the adhesive mixes, the addition of ammonium sulphate as hardener was 0.5% for UF I and 0.3% for UF II and UF III, both values expressed as solid ammonium sulphate on resin solids. An equal gel time was considered to be essential for the comparison of the penetration of the various adhesive mixes into wood, since the length of hardening process influences the penetration behaviour due to increase of the molecular size. 2.3 Bonded samples and determination of the shear strength The three adhesive mixes were applied by a rubber roller onto one surface of the two wood specimens to be bonded; the applied amount was 200 g/m2. Assembling was performed with parallel grain directions, whereby the ply without direct application of adhesive always was in the bottom position, in order to improve the penetration into its structure. Five bonding samples were pressed in a hydraulic press at 120°C and 1.0 MPa for 15 minutes. Ten samples had been prepared for each of the three UF adhesives mixes. Prior to testing the lap shear test specimens were conditioned at a relative humidity of 65% ± 5% and a temperature of 20 ± 2oC. Tests were conducted on a hydraulic test machine (ZWICK, Germany) with a measuring scale of 50 kN and at a testing speed of 6 mm/min in tensile mode. The shear strength m (MPa) of the adhesive joint was calculated as usually from shear force and width and length of overlap. The shear area was examined using a light microscope in order to determine the proportion of wood failure and the thickness of the wood layer in the wood failure. Ten replications had been performed for each set of parameters. 1465 3 Results and discussion Table 1 summarizes the achieved shear strengths and the wood failure for the twelve combinations tested: three adhesives with different degree of condensation (UF I, UF II, and UF III), two wood species (fir and beech), and two cutting directions (radial and tangential) per combination. Fir Beech Table 1. Shear strength (MPa), wood failure (%), and thickness of wood failure (mm) of the tested adhesive joints Adhesive Direction of penetration Shear strength (MPa) Standard deviation (MPa) Wood failure (%) Thickness of wood failure (mm) Shear strength (MPa) Standard deviation (MPa) Wood failure (%) Thickness of wood failure (mm) UF I T 10.4 0.83 65 0.5 5.0 0.46 90 0-1 UF II R 11.4 1.09 70 0.5 5.6 0.60 80 0-1 T 9.5 0.42 70 0.5 4.5 0.52 90 0-1 R 10.4 0.87 75 0.5 5.0 0.31 80 0-1 UF III T R 9.0 9.7 0.55 0.54 70 75 0.5 0.5 4.2 4.6 0.47 0.51 90 80 0-1 0-1 T: tangential penetration; R: radial penetration For beech the wood failure for radial and tangential penetration is in the range of 65 – 75% and occurs close to the bond line in the interphase. With fir at radial penetration (annual rings are parallel to the bond line) two different situations can be distinguished, whereby the failure depends on the wood structure (early or late wood) at the shear zone. For early wood the wood failure is preferably within the wood substance with 100 % wood failure; the thickness of the wood failure is between 0 and 1 mm (partly even up to 2 mm). With late wood at the shear zone, the failure mainly occurs directly in the adhesive; the thickness of wood failure, hence, is close to 0 mm. However, the share of late wood in the annual rings of fir is only 20 %; as an average of both, early wood and late wood close to the bond line, the wood failure is approximately 90%. With fir at tangential penetration the annual rings are perpendicular to bond line. Along the late wood portions the failure occurs cohesively within the adhesive layer, whereas along early wood it occurs more or less deeply within the wood substance, reflecting a failure surface profile similar to saw teeth. In this group of samples the wood failure is lower, but still at 80%. The thickness of the wood failure is 0 mm along the late wood and up to 1mm (with some peaks having 2 mm) in the early wood area. Influence of the molar masses (degree of condensation) The diagrams in figure 1 shows the shear strengths of the various tested adhesive joints as function of the molar masses (degree of condensation), whereby the viscosity of the applied adhesives (UF I, UF II, UF III) was taken as measure on the x-axis in the diagrams; data are shown for the two wood species (beech and fir) and for the two penetration directions (tangential and radial). 1466 Beech - radial penetration Beech - tangential penetration 13 UF III 10 m (MPa ) UF II 11 Shea r strength UF I 12 m (MPa ) Shea r strength 13 12 UF I 11 UF II 10 9 9 8 8 0 250 500 750 1000 1250 1500 0 1750 250 500 Fir - radial penetration 1250 1500 1750 7 UF I UF I UF III 5 4 3 2 m (MPa ) 6 UF II Shear strength m (MPa ) 1000 Fir - tangential penetration 7 6 750 Viscosity (mPa ·s) Viscosity (mPa ·s) Shea r strength UF III UF II 5 UF III 4 3 2 0 250 500 750 1000 1250 Viscosity (mPa·s) 1500 1750 0 250 500 750 1000 1250 1500 1750 Viscosity (mPa·s) Figure 1. Shear strengths of the various adhesive joints with the three adhesive mixes based on UF I, UF II, and UF III at radial and tangential penetration for beech and fir: upper row: left: beech, radial penetration; right: beech, tangential penetration; lower row: left: fir, radial penetration; right: fir, tangential penetration. The bars indicate the standard deviation. The shear strengths of the bond line, as well as the mean penetration depths (AP) and the sizes of the interphase region (IR) (Gavrilovic-Grmusa et al. 2010 a+b) are inverse proportional to the viscosity of the adhesive mixes, caused by the different degrees of condensation of the adhesive. Figure 2 shows the correlations between the shear strength and the average penetration depth (AP) as AP was reported earlier (Gavrilovic-Grmusa et al. 2010 a+b). For beech the increase in shear strength for the adhesive UF I with the lowest viscosity compared with UF III with the highest viscosity and, hence, with the lowest penetration ability, is in average approximately 1.5 MPa for beech and close to 1 MPa for fir (in each case approximately 15% on a coarse scale). 1467 Beech- tangential penetration Beech- radial penetration 13 13 11 UF III 10 UF I 9 12 m (MPa ) UF II Shear strength m (MPa) Shea r strength 12 UF I 11 UF III 10 9 8 8 100 150 200 250 100 300 6 6 5 UF I UF II 3 2 m (MPa ) 7 UF III 200 250 300 Fir- tangential penetration 7 Shera strength m MPa) Fir- radial penetration 4 150 Avera ge penetration depth (mm) Avera ge penetration depth (mm) Shea r strength UF II UF III 5 UF II UF I 4 3 2 100 150 200 250 Average penetra tion depth (mm) 300 100 150 200 250 300 Avera ge penetration depth (mm) Figure 2. Correlations between the average penetration depth AP and the shear strengths for the relevant sets of parameter: Upper row, left: beech, bond line between tangentially cut surfaces (radial penetration); right: beech, bond line between radially cut surfaces (tangential penetration); lower row, left: fir, bond line between tangentially cut surfaces (radial penetration); right: fir, bond line between radially cut surfaces (tangential penetration). Even the wood failure is quite high, the differences in the shear strength between the various adhesives used come from the fact, that at a higher thickness of the interphase a bigger portion of the wood failure occurs in the fortified interphase and less portion of the wood failure occurs in the “pure” wood, where no penetration had occurred. This fortification, hence, results in higher shear strengths. Similar correlations can be seen between the shear strength of the joint and the size of the interphase region, as reported by Gavrilovic-Grmusa et al. (2010 a+b) for different wood species, directions of penetration, and resin types. In all cases the shear strengths increase with AP and with IR. Both, AP and IR, describe the fortification of the wood substance due to penetration of the adhesive into the wood surface. This penetration is higher, when the adhesive shows a lower viscosity due to the lower degree of condensation and, hence, due to the smaller molecules in the stage before hardening, when penetration can occur. It still is questionable, if the higher shear strength preferably derives (i) from an enhanced mechanical interlocking effect or (ii) rather from a fortification of the wood structure in the subsurface due to the penetrated adhesive, and hence, from a higher wood shear strength. The more wood failure occurs in this fortified 1468 interphase, the higher will be the bond strength, even when predominantly observing wood failure. The thickness of the interphase is still lower than the average thickness of the wood failure. This underlines the variable fortification of the interphase by the penetrated resin, shifting the failure zone deeper into solid wood. Influence of wood species Beech Fir 12.0 Tangential penetration Radial penetration 11.0 10.0 m (MPa) Shear strength of adhesive joint The shear strengths of the tested adhesive joints between radial and tangential surfaces are compared for the two wood species in figure 3. For all adhesives and cutting directions the shear strengths are greater for beech than for fir, which is a known fact based on the different densities and the different wood strengths themselves. 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 UF I UF II UF III UF I UF II UF III Figure 3. Shear strength m of the various adhesive joints tested Influence of the penetration direction The measured shear strengths as well as the size of the interphase region are for both wood species and for all three adhesive mixes at radial penetration higher compared to the tangential direction, even the average tangential penetration depth is higher and the filled interface region is lower then at the radial penetration. This means that mainly the maximal penetration depth, defining the size of the interphase region, influences the shear strength. This also underlines the obvious fortification of the interphase due to the penetration of the adhesive. 1469 Acknowledgements The research work presented in this paper was financed by the Ministry of Science and Technological Development, Project “Wood biomass as a resource of sustainable development of Serbia” 20070-TP. We are grateful indebted to Ing.Petr Pastrnak of DUKOL, Ostrava s.r.o., for the preparation of the UF resins used in the investigations reported in this paper. 1470 REFERENCES Dunky M. (2003), Wood Adhesives. In: Handbook of Adhesive Technology, 2nd Ed., Pizzi A., Mittal K.L.(Eds.), pp. 887-956, Marcel Dekker, New York Dunky M., Pizzi A. (2003), Wood Adhesives. In: Adhesion Science and Engineering, Volume 2: Surfaces, Chemistry and Applications, Dillard D.A., Pocius A.V.(Eds.), pp. 1039-1103, Elsevier Ferg, E.E., Pizzi, A., Levendis, D.C. (1993), 13C NMR analysis method for ureaformaldehyde resin strength and formaldehyde emission, J.Appl.Polym.Sci. 50, 907 - 915 Gavrilovic-Grmusa I., Dunky M., Miljković J., Điporović-Momčilović M. (2010): Radial penetration of urea-formaldehyde adhesive resins into beech (Fagus Moesiaca), J.Adhesion Sci.Technology, 24, 1753–1768 (a) Gavrilovic-Grmusa I., Miljković J., Điporović-Momčilović M. (2010), Influence of the degree of condensation on the radial penetration of urea formaldehyde adhesives into Silver Fir (Abies alba, Mill.) wood tissue, J.Adhesion Sci. Technology, 24, 1437–1453 (b) Nakarai, Y., Watanabe, T. (1962), Wood Adhesives and bond strength, Wood Industry 17, 464 - 468 Pizzi, A. (1983): Wood Adhesives, Chemistry and Technology. Marcel Dekker Inc., New York, Basel Rice, J.T. (1965), The Effect of Urea-Formaldehyde Resin Viscosity on Plywood Bond Durability, Forest Prod. J. 15, 107 – 112 Scheikl M., Dunky M. (1996), Software supported static and dynamic methods for contact angle measurement during wetting of wood, Holz Roh.Werkst. 54, 113 – 117 Scheikl M., Dunky M. (1998), Measurement of dynamic and static contact angles on wood for the determination of its surface tension and the penetration of liquids into the wood surface, Holzforschung 52, 89 - 94 1471