JUNE 1, 2013 VERSION 1.0 POLY FLO Features The Saval polymer

advertisement

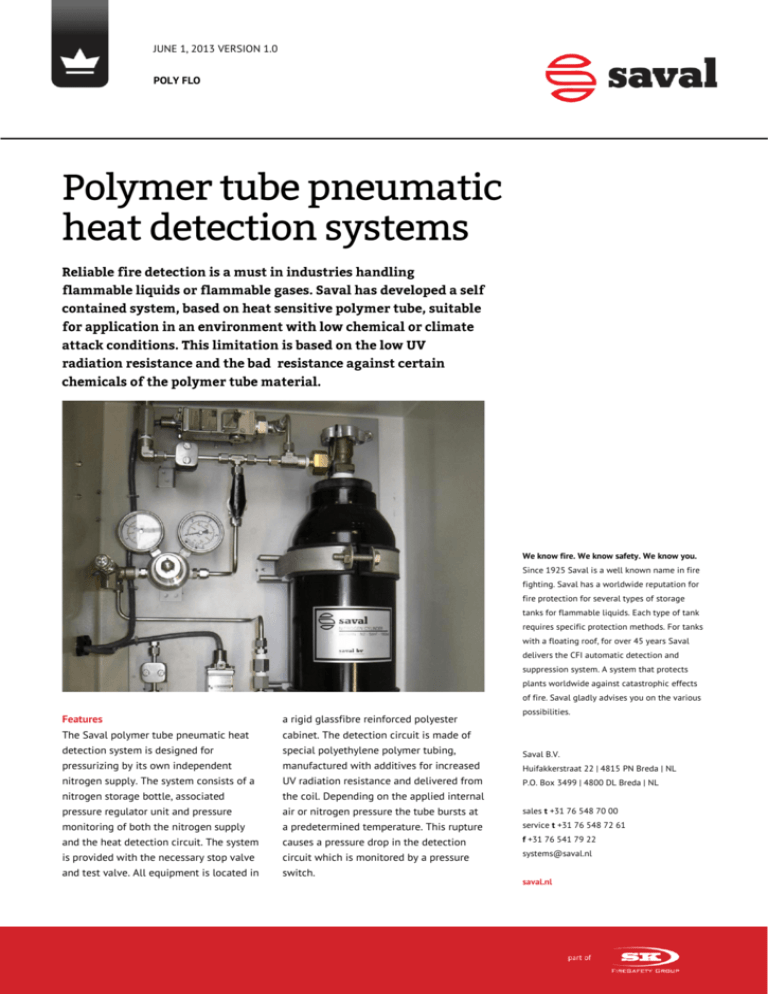

JUNE 1, 2013 VERSION 1.0 POLY FLO We know fire. We know safety. We know you. Since 1925 Saval is a well known name in fire fighting. Saval has a worldwide reputation for fire protection for several types of storage tanks for flammable liquids. Each type of tank requires specific protection methods. For tanks with a floating roof, for over 45 years Saval delivers the CFI automatic detection and suppression system. A system that protects plants worldwide against catastrophic effects of fire. Saval gladly advises you on the various possibilities. Features a rigid glassfibre reinforced polyester The Saval polymer tube pneumatic heat cabinet. The detection circuit is made of detection system is designed for special polyethylene polymer tubing, Saval B.V. pressurizing by its own independent manufactured with additives for increased Huifakkerstraat 22 | 4815 PN Breda | NL nitrogen supply. The system consists of a UV radiation resistance and delivered from P.O. Box 3499 | 4800 DL Breda | NL nitrogen storage bottle, associated the coil. Depending on the applied internal pressure regulator unit and pressure air or nitrogen pressure the tube bursts at sales t +31 76 548 70 00 monitoring of both the nitrogen supply a predetermined temperature. This rupture service t +31 76 548 72 61 and the heat detection circuit. The system causes a pressure drop in the detection f +31 76 541 79 22 is provided with the necessary stop valve circuit which is monitored by a pressure systems@saval.nl and test valve. All equipment is located in switch. saval.nl POLY FLO Typical applications for these nitrogen malfunctioning. based heat detection systems are floating Quality Assurance and Quality Control. Saval has an integrated quality control roof storage tanks, fixed roof storage Technical data system in accordance with the tanks, horizontal drums and vessels, Nitrogen is stored at an initial pressure of international standard ISO 9001, which is flammable liquid transfer pumps, process 200 bar. The contents of the nitrogen certified by Lloyd’s. This approval skids etc. bottle is monitored by a pressure switch represents the total commitment of the An alternative system for pressurizing by set at 50 bar decreasing pressure. This will entire organisation, not only in the an uninterrupted supply of plant enable the plant operator to schedule the production process but also for design, instrument air is available as an option. replacement of the nitrogen bottle in due administrative procedures and after sales This system consists of a supply unit course. The detector circuit pressure is set service. containing a pressure regulator and stop on 5 bar. After a rupture of the tube due to valve and a monitoring unit at the end of a local heating the circuit pressure will Saval's polymer tube pneumatic heat detection circuit containing a pressure decrease and a low pressure switch will detection systems are the best systems switch and a test valve. Both units are operate at 2 bar decreasing pressure. The available for application in moderate mounted on a stainless steel plate. primary and secondary side of the pressure environmental or process conditions and regulator are provided with safety relief guarantee an acceptable life with little Manufacturing valves. A stop valve in the primary side of maintenance. All parts used for the prefabrication of the the pressure regulator enables the change control cabinet or control units are made of the nitrogen bottle without interrupting of corrosion resistant materials for the the operation of the system and a test intended good climatological or chemical valve is provided in the secondary side for conditions. All components are selected check on proper operation of the system. from high class suppliers, specially suitable for the intended reliable Ambient temperature limits of the system: operation. minus 30°C to plus 70°C Corrosion resistance Operating temperature of polymer tube The use of corrosion resistant materials depends on internal pressure: meets the required demands with regard 100°C @ 5,6 bar to reliable operation in the moderate conditions as described earlier. Maximum length of a tube detection loop: 300 metres. ▪ Restricted chemical resistant ▪ Corrosion resistant Engineering ▪ Little maintenance Saval has installed fire detection and ▪ Standard components protection systems all over the world for ▪ Easy to install more than 40 years. During this period ▪ For use in hazardous areas Saval has become the specialist in these systems specially in the oil and The Saval polymer tube heat detection petrochemical industry and LNG system is purposely designed for moderate production industry.. Research and field environmental and process conditions. The experience gained with the systems has result is a reliable, rigidly constructed been used to develop and improve these system with little maintenance and little systems. For every application, the Saval chance of unwanted fire alarms due to team will offer a custom-designed system. Storage tank