Test Readiness Review presentation Template

advertisement

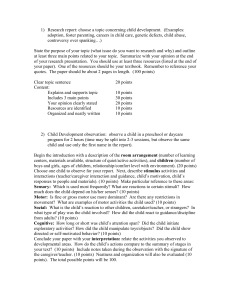

ATK Advances In Solid Propulsion Presented to: SPST POC: David McGrath Email: david.mcgrath@atk.com Phone: (410) 392 - 1716 October 9, 2014 EXPORT-CONTROLLED/FOR OFFICIAL USE ONLY Outline • Orion Launch Abort Attitude Control Motor and Abort Motor • LDSD • STAR 48GXV • SLS • Stratolauncher • Summary -1- ATK Has Developed the First Human Rated Solid Control System – The Orion LAS ACM Successful Flight Testing – PA-1 Successful Component Development Testing HT-6 Actuators Controller HT-8A Igniter Battery Software Successful Full Scale Development Testing Accomplishments • Program start to first full scale test in 29 months, flight in 34 months DM-2 • Human-rated, single fault tolerant valve control system and software • Eight, fully proportional valves using new high temperature materials DM-1 • Greater than 7,000 lbf omni-axis thrust capability with 100 msec response time -2- ACM Design Overview Controller Assembly • Single-fault-tolerant controller circuits with arbiter Gas Generator Assembly • Valve compatible propellant • Steel case and closure Lithium-Ion Battery Assembly • Two, redundant command/control and valve power batteries Valve Assemblies • Eight proportionally controlled pintle valves, redundant motors in actuators • Aluminum skirts and controller/battery stand -3- DM-1 and DM-2 Test Parameters • • • • DM-1 Key Parameters Conditioning Temperature: 60°F Valves: 8 Burn time: ~30 sec Maximum thrust: ~7000 lbf • • • • DM-2 Key Parameters Conditioning Temperature: 40°F Valves: 8 Burn time: ~30 sec Maximum thrust: ~7000 lbf -4- Proportional Valve Description Redundant Actuator Carbon/Phenolic Exit Cone 6Al-4V Titanium Housing and Nozzle Ring C/C-SiC Pintle, Guide, and Throat PA-1 Valve Assembly Shown Valve Thrust:Weight ~250:1 -5- DM-2 Test Video Top View -6- DM-2 Top View Video -7- PA-1 Flight Test – May 6, 2010 Ref: NASA Orion website information Controlled Re-orient Controlled Ascent Pitchover LAS Jettison The ACM performed flawlessly during the PA-1 flight – meeting all objectives ACM Ignition -8- High Thrust Valve Tests – HT-9 and HT-10 • Test single valve at full open conditions • Determine valve material response to full loading conditions during hot gas testing • Measure pressure and thrust • HT-9 successfully tested on Feb. 12, 2014 • HT-10 test is intended to be a margin type test with a goal of achieving 1.4 x MEOP pressure conditions at full open -9- Path Forward and Summary • The qualification program is getting underway – Three motors are planned for the qualification program – CDR is expected to occur in 2015 – Flight deliveries to begin in 2018 • The ACM is the first single-fault tolerant proportionally controlled solid propellant system to be developed and flown • The ACM incorporates C/C –SiC materials for the pintle, pintle guide and throat • ATK Missile Defense and Controls is honored to be part of the next steps in human spaceflight away from planet Earth on the Orion project -10- Orion LAS Abort Motor -11- Abort Motor Hardware Manufacturing Abort Motor 1800 Gallon Mix Abort Motor Case Tooling & Winding Abort Motor Manifold Abort Motor Igniter Tooling & Winding -12- Abort Motor ST-1 Test Firing - ~500,000 lbf thrust -13- Pad Abort 1 Abort Motor -14- PA-1 LAV During Ascent and Post Mission. Recovered Igniter Slag -15- EFT-1 Inert Abort Motor EFT-1 Rework for Flight • Manifold Replaced • Case Line Loads Test Completed • Midcase Installed • TPS Installed • Raceway Installed • Build Paperwork Review • Verification for Flight ATK Inert Pathfinder Used in LAS Structural Test Article Used in Orion Ground Test Article Refurbished and Certified for EFT-1 EFT-1 Inert Abort Motor Reused Multiple Times in Support of Program Affordability -16- AM Qualification Path Forward High Thrust Turn-Flow Abort Motor w/ Head End Nozzles – Fabrication of 3 Full-Scale (QM series) qualification Abort Motors and static test firing under representative load conditions – Test stand mods required to get accurate motor induced acoustics – Fabrication of demonstration Abort Motors for LAS high altitude operational flight tests (AA-2 High Altitude) High Burn Rate Class Propellant • Mix/Cast/Cure, Acceptance Testing (subscale motors and expanded lotto-lot variability mechanical testing. Firing in full scale tests. High Mass Flow Pyrogen Igniter • Fabrication of 2 qual Igniters and bench test firings • Fabrication and test in full-scale Abort Motor test firings listed above Direct Strike Lightning Protection (Integrated w/ TPS) • Conducted preliminary TPS Aero and Plume heating and ablation tests • Complete integrated Lightning and TPS process development trials • Conduct coupon level and joint E3 qualification testing • Integrated TPS/DSL design environmental characterization/qualification testing • Structural Qualification • Material allowables testing Pressurized and unpressurized structural case and manifold ultimate loads testing -17- Low Density Supersonic Decelerator (LDSD) -18- LDSD - Issues for Large Payloads at Mars • Very large payloads being considered for manned flights – Tens of thousand of kilograms • Payload fairings of launchers from Earth are fixed in size – (5-10m for SLS) • Inflatable systems being studied • Low Density Supersonic Decelerator (LDSD) program being funded by JPL to perform risk reduction testing to gather data for future designs • ATK Elkton under contract to JPL for STAR motors for testing – Also being considered for future mission applications -19- LDSD Mission Rev: 0 -2020 Dec 12 LDSD Pictures • One successful flight conducted to-date -21- STAR 48GXV -22- STAR 48GXV • Development began as a risk reduction for the Solar Probe mission – Vehicle change negates the need for the motor • High performance, graphite epoxy case, TVC, carbon-carbon exit cone • Expected vacuum delivered Isp of >308 lbf-sec/lbm • First development motor successfully fired in December 2013 -23- SLS Booster -24- SLS Booster • ATK is developing the 5 segment booster for SLS • Builds on Shuttle heritage • Three development motors successfully tested • Program has passed CDR • Qual motor 1 is being processed for a test in 2015 -25- Stratolaunch -26- Stratolaunch • Stratolaunch Systems is owned by Paul Allen • The carrier aircraft is being built by Scale Composites • The launcher effort is being led by Orbital – Launcher has solid lower stages and liquid upper stage – ATK is supporting Orbital on the solid stages -27- Summary • ATK is actively developing new propulsion systems for future space mission applications • Controllable solid propulsion offers capability for a variety of control applications • ATK has provided propulsion for every manned US space mission and many spacecraft boost, retro, and landing applications -28-