products corporation

advertisement

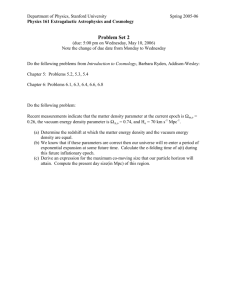

Model CVS--1 Central Vacuum Cleaning System EQUIPMENT SELECTION . . . . . . . . . . . Ordering No. TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . Page Model HS--1 Front Leg Cleaner . . . . . . 3019248 Model HS--2 Rear Hock Cleaner . . . . . 3019249 Balancer . . . . . . . . . . . . . . . . . . . . . . . 4042002 Model CV--1 Carcass Cleaner . . . . . . . 3019173 Model CV--1 Spinal Cord Remover Beef with steam . . . . . . . . . . . . . . . . . 3019176 Pork with steam . . . . . . . . . . . . . . . . . 3019207 Model SR--1 Spinal Cord Remover Pork without steam . . . . . . . . . . . . . . 3019174 Beef without steam . . . . . . . . . . . . . . 3019205 Model FV--1 Floor Cleaner . . . . . . . . . . 3019251 Vacuum Pump Assembly . . . . . . . pages 16--19 Gauge Panel Assembly . . . . . . . . . . . . . 3025013 Vacuum Sediment Tank . . . . . . . . . . . . . page 21 Vacuum Filter Assembly . . . . . . . . . . . . page 21 Auto Dump Valve, 115 Volt . . . . . . . . . . 3022089 Auto Dump Valve, 230 Volt . . . . . . . . . . 3022111 Gravity Dump Valve . . . . . . . . . . . . . . . . 3022096 • Notice to Employer and Safety Director . 2 JARVIS 6239003.b • Notice to Operators, Maintenance and Cleanup Personnel . . . . . . . . . . . . . . . 3 • Parts Diagram and List . . . . . . . . . . . . . . . 4 • Specifications . . . . . . . . . . . . . . . . . . . . . . 26 • Installation Instructions . . . . . . . . . . . . . . 27 • Operation Instructions . . . . . . . . . . . . . . . 29 • Maintenance Instructions . . . . . . . . . . . . 30 • Vacuum Pump Trouble Shooting Chart 32 ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW.jarvisproducts.com notice to employer and safety director Model CVS--1 Vacuum Cleaning System page 2 of 32 Hot surfaces. Do not touch. NOTICE TO EMPLOYER AND SAFETY DIRECTOR AVOID INJURY 1. Remove and repair any tool that malfunctions. All personnel must be instructed to remove any malfunctioning equipment. 2. Ensure that all employees who use this equipment are trained in it’s proper use and are aware of the dangers that may arise if they do not follow procedures outlined in this brochure. 3. Enclosed are four (4) copies of “NOTICE TO OPERATORS, MAINTENANCE AND CLEANUP PERSONNEL.” Post one copy on the employees’ bulletin board; give one copy to operator(s); give one copy to the maintenance foreman; and give one copy the sub-contract cleanup / internal cleanup foreman. Additional copies will be provided upon request. 4. This equipment utilizes pressurized steam that can cause serious burns. This fact should be obvious to your employees, but you must emphasize it to them. 5. Never make modifications or alterations to the equipment. Replace any missing or illegible labels. 6. Ensure that proper procedures are established for all equipment (in accordance with OSHA’s lockout/ tagout procedures 29 CFR 1910.147) to prevent accidental startup or release of stored energy. 7. Always disconnect the equipment from it’s electrical and steam supply when it is not in use. 8. Follow our installation and maintenance instructions for proper installation and care of the equipment. 9. Avoid injury. Do not permit the equipment to be misused. 10. Avoid prolonged exposure in vicinity of vacuum pump assembly. Ear protection may be required. 11. If you resell or distribute a Jarvis product, you must provide the purchaser with the appropriate safety sheets and tool brochure. Additional copies of safety sheets and tool brochures will be provided upon request. JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com notice to operators, maintenance and cleanup personnel page 3 of 32 Model CVS--1 Vacuum Cleaning System Hot surfaces. Do not touch. NOTICE TO OPERATORS, MAINTENANCE AND CLEANUP PERSONNEL REMOVE ANY MALFUNCTIONING TOOL FROM SERVICE REPORT ANY PROBLEMS TO YOUR SUPERVISOR Steam Cleaner Handle 1. Never put fingers, hands or other parts of the body on the metal portion of the steam vacuum handle or in the steam discharge path. 2. Opening the steam valve will cause a high temperature fluid to flow continuously through the tool handle and out the steam nozzle. Be sure to look around the area where the handle is situated to prevent accidental scalding. Wear protective gloves when operating the tool. 3. Never open the steam valve unless you want to use the tool. 4. Never stand in front of the handle inlet while the vacuum pump is operating. Exposed skin could be drawn into the opening. Always wear proper personal protective equipment when operating the tool. 5. Never make any alterations to the handle. Steam Cleaner System 6. Shut off the steam supply and allow time for the metal to cool before touching the vacuum head. 7. Shut off the steam supply before performing any repairs or maintenance. 8. Shut off the steam supply before performing any cleanup. 9. Shut off the steam supply and vacuum pump when the tool is not in use. Vacuum Pump 10. Disconnect the electric power supply before performing any repairs or maintenance. 11. To prevent an explosion hazard, never use combustible liquids to clean the rotor assembly. 12. Never operate with belt guard or coupling shield removed. 13. Never loosen or remove the oil filler plug, drain plugs, covers, or break any connections in the pump discharge or oil system until the unit is shut down. 14. Never operate vacuum pump with open inlet or outlet port. 15. Never exceed specified vacuum limits. 16. Always use care before touching vacuum pump and discharge piping. They may be extremely hot and can cause skin burns on contact. JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 4 of 32 Figure A System Overview ITEM 1 2 3 4 5 6 7 8 9 10 11 PART NO. page 21 pgs 16--19 pg 22 or 24 page 23 page 21 page 5 page 6 pgs 7--9 page 7 page 10 page 11 page 20 page 12 page 12 page 13 page 14 page 15 JARVIS 6239003.b ® PART NAME Vacuum Filter Assembly Vacuum Pump Assembly Auto Dump Valve Assembly Auto Dump Control Box Assembly Vacuum Sediment Tank Floor Cleaner Handpiece Spinal Cord Remover without Steam Carcass Steam Cleaner Handpieces Spinal Cord Remover with Steam Front Leg Cleaner Rear Hock Cleaner Gauge Panel Assembly Fecal Debris Remover, Pork Head Cleaner, Pork Bung Cleaners Beef and Pork Steam Cleaner and Acid Dispenser Brain Sucker and Tail Cleaner PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 5 of 32 Figure B FV-- 1 Floor Cleaner 3019251 ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 JARVIS 6239003.b ® PART NO. 1022268 1051198 1051199 1059123 1059122 1012122 1061895 1032584 1061896 1007043 1007183 1057091 1009165 1055031 1055336 1045008 1017168 3019251 PART NAME QTY Ball Valve 1 Hose Coupling, Female 1 Hose Coupling, Male 1 Hose Cuff 2 Vacuum Hose 25 ft Hose Clamp 1 Floor Cleaning Nozzle 1 Backup Plate 1 Rubber Flap 1 Hex Lock Nut 8 Hex Lock Nut 2 Plastic Wheel 2 Sleeve 2 Hex Head Screw 2 Hex Head Screw 8 Blind Rivet 2 Nameplate Label 1 Floor Cleaning Handle Assy (items 1--17) PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 6 of 32 Figure C SR-- 1 Spinal Cord Remover without steam 3019174 3019205 * * Optional ITEM 1 2 3 4 5 6 7 8 9 10 PART NO. 1050640 1050639 1059086 1050688 1061698 1019184 1061779 1061751 1055743 1019172* 3019174 3019205 PART NAME Adapter Rigid Screw Cuff Hose (10 ft.) Swivel Connector Tube Grip Handle Nozzle, Beef Nozzle, Pork Set Screw Pistol Grip Handle Handle Assembly, Pork Handle Assembly, Beef JARVIS 6239003.b QTY 2 2 1 1 1 1 1 1 2 1 ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 7 of 32 Figure D CV-- 1 Carcass Cleaner with steam 3019173 * * * * Figure E CV-- 1 Spinal Cord Remover with steam 3019176 Beef 3019207 Pork * * * * Optional Y For Steam Vacuum Cleaning System JARVIS 6239003.b *Y ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 8 of 32 Figure F Optional Nozzles for Steam Cleaning 3061224* 3061223* 3061256* * Optional ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 PART NO. 1050621 1050638 1059084 1012092 1050656 1035505 1050614 1042362 1019169 1017285 1016484 1025036 1013255 1024193 1024184 1055743 1055945 1035504 1061727 1035506 1050755 1059106 1050628* 1050659* 1050629* 3050006 26 27 28 29 1050632 1050631 1007310 1016493 PART NAME QTY Fitting 1 Swivel Cuff 2 Vacuum Hose 10 ft Cable Tie 4 Adapter 1 O--ring 3 Reducing Bushing 1 Handle Bracket 1 Handle (includes item 10) 1 Danger Label 1 Steam and Vacuum Head 1 Temperature Gauge 1 Retaining Ring 1 Plastic Window Guard 1 Gauge Guard 1 Set Screw 3 Hex Head Screw 2 Gasket 1 Steam Nozzle Cap, Long 1 O--ring 2 Elbow, 45° (includes item 20) 1 Steam Hose 1 Adapter 1 Swivel Connector 1 Reducer Bushing Fitting 1 Swivel Adapter Kit (Includes items 6, 23--25) Adapter 1 Elbow Adapter (incls item 20) 1 Nut 1 Housing 1 JARVIS 6239003.b ® ITEM 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 PART NO. 1035515 1035514 1061703 1061745* 1061704* 1061746 1061786 1061696* 8030055* 1055746* 1061737* 1035511* 1061688* 1061691* 1055742* 1055613* 1061692* 1035512* 1061690* 1061730* 1061728* 1061687* 3059032 3019173 3019176 3019207 3061256* 3061223* 3061224* PART NAME O--ring O--ring Steam Nozzle Cap Scraping Finger Scraping Finger Scraping Finger (Beef) Scraping Finger (Pork) Steam Nozzle Cap Wrench for item 28 Socket Head Screw Adapter Gasket Steam Nozzle Cap Adapter Socket Head Screw Socket Head Screw Adapter Gasket Steam Nozzle Cap Steam Nozzle Cap Steam Nozzle Cap Steam Nozzle Cap Vacuum Hose Assy, 10 ft (includes items 2 and 3) Handle Assembly (includes items 1--22) Handle Assy, Beef (incls 1--10, 12--16, 20--22, 26--32 and 35) Handle Assy, Pork (incls 1--10, 12--16, 20--22, 26--32 and 35) Nozzle Assembly (includes (items 17, 18 and 38--41) Nozzle Assembly (includes items 17, 18 and 40--43) Nozzle Assembly (includes items 18 and 44--47) QTY 1 1 1 1 1 1 1 1 1 1 2 1 1 1 2 2 1 1 1 1 1 1 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 9 of 32 Figure G Optional Handpieces for Steam Cleaning Ultra--Light Weight 3019300 Ultra--Light Weight 3019241 Light Weight 3019299 Light Weight 3019244 Ultra--Light Weight 3019231 3019339 ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 PART NO. 1059106 1061863 3019239 1059105 1059104 1012092 1050755 1035506 1016586 3019238 3016388 1012149 1055743 1071093 3061366 PART NAME QTY Steam Hose, 10 ft 1 Nozzle 1 Handle And Swivel Assembly 1 Hose Cuff 2 Vacuum Hose 10 ft Cable Tie 2 Adapter Elbow, 45 Degree 1 O--ring (with item 7) 1 Steam and Vacuum Housing 1 Handle And Swivel Assembly 1 Steam and Vacuum Housing 1 Clamp 1 Socket Set Screw, Cup Pt 2 Teflon Tubing 1 Tube Assembly with item 13 1 JARVIS 6239003.b Light Weight 3019242 ® ITEM 16 17 18 19 20 21 22 PART NO. 1050857 3019297 1055087 1004262 1055752 1061869 1071095 PART NAME QTY Connector 45 Degree Elbow 1 Handle And Swivel Assembly 1 Socket Set Screw, Cup Pt. 1 Washer 2 Hex Head Screw 2 Nozzle Assembly, 4 inch 1 Nozzle Assembly, 8 inch 1 3019231 3019339 3019241 3019300 3019242 3019244 3019299 Handle Assy, 4 in, Steam Out Handle Assy, 4 in, Steam In Handle Assy, 2 in, Steam Out Handle Assy, 8 in, Steam Out Handle Assy, 4 in, Steam In Handle Assy, 4 in, Steam In Handle Assy, 4 in, Steam In PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 10 of 32 Figure H HS--1 Front Leg Cleaner 3019248 ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 PART NO. 1051115 1051063 1051069 1022281 1059106 1011371 1007021 3019255 1017423 1012151 1059144 1051161 1055046 1061448 1019192 PART NAME QTY Air Fitting 2 Street Tee 1 Air Bleed Fitting 1 Hot Water Valve 1 Steam Hose 1 Eye Bolt 1 Hex jam Nut 1 Front Leg Handpiece w/item 9 1 Warning Label, Open Vac/Hot Hose Clamp 2 Vacuum Hose 10 ft Elbow Fitting 2 Hex Head Screw 1 Red Plastic Tubing 16 ft ”D” Handle with item 23 1 JARVIS 6239003.b ® ITEM 16 17 18 19 20 21 22 23 24 25 26 27 PART NO. 1022211 1054153 1018020 1012033 1024035 1055134 1010235 1055043 1004073 1004003 1061449 1051007 PART NAME Valve Threaded Plug Trigger Lever Trigger Guard Clamp Trigger Guard Socket Head Cap Screw Dowel Pin Socket Set Screw, Cup Pt. Split Lock Washer Lock Washer Blue Plastic Tubing Quick Connect Plug 3019248 Front Leg Cleaner Assy (includes items 1--27) QTY 1 1 1 1 1 2 1 1 1 1 16 ft 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 11 of 32 Figure I HS--2 Rear Hock Cleaner 3019249 ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 PART NO. 1055134 1024035 1012033 1010235 1018020 1004073 1004003 1054153 1022211 1019192 1055046 1055043 1051161 1061449 1011371 1007021 PART NAME Socket Head Cap Screw Trigger Guard Trigger Guard Clamp Dowel Pin Trigger Lever Split Lock Washer Lock Washer Threaded Plug Valve ”D” Handle with item 12 Hex Head Screw Socket Set Screw, Cup Pt. Elbow Fitting Blue Plastic Tubing Eye Bolt Hex jam Nut JARVIS 6239003.b QTY 2 1 1 1 1 1 1 1 1 1 1 1 2 16 ft 1 1 ® ITEM 17 18 19 20 21 22 23 24 25 26 27 PART NO. 1061448 1051115 1051007 1059106 1022281 1051063 1051069 3019256 1017423 1012151 1059144 3019249 PART NAME QTY Red Plastic Tubing 16 ft Air Fitting 2 Quick Connect Plug 1 Steam Hose 1 Hot Water Valve 1 Street Tee 1 Air Bleed Fitting 1 Rear Hock Handle w/item 25 1 Warning Label, Open Vac/Hot 1 Hose Clamp 2 Vacuum Hose 10 ft Rear Hock Cleaner Assy (includes items 1--27) PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 12 of 32 Figure J FDR Fecal Debris Remover Pork 3019229 3019319 ** Figure K Head Cleaner Pork 3019272 3022083 * * Set regulator (item 28) to 60 psi. ** To adjust regulator (item 28): cover trigger hole in item17. Turn regulator cw until valve (item 23) opens. If valve does not close when trigger is uncovered, back off regulator slightly. ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 PART NO. 1019230 3061321 1012075 1059105 1059104 1059106 1055212 1054145 1007021 1032609 1061986 1050639 1059103 3061289 1051124 1055079 1019208 1055026 1031033 1061834 1051192 1050216 PART NAME Handle Tube Assembly Hose Clamp Hose Cuff Vacuum Hose Steam Hose Hex Head Screw Eye Bolt Hex Jam Nut Mounting Plate Mounting Block Rigid Screw Cuff Vacuum Hose, 15 ft Tube Assembly Fitting Socket Set Screw, Cup Pt. Handle Socket Set Screw, Cup Pt. Hub Plastic Tubing Connector Hex Socket Plug JARVIS 6239003.b QTY 1 1 2 2 10 ft 1 4 1 1 1 1 2 1 1 1 4 1 2 1 15 ft 1 2 ® ITEM 23 24 25 26 27 28 29 30 31 32 33 34 35 36 PART NO. 1022246 1050016 1050053 1034060 1025049 1022066 1061253 1051191 1050027 1050674 1050071 1011175 1061835 3022084 PART NAME Air Valve Hex Nipple Tee Air Filter Pressure Gage Pressure Regulator Yellow Tubing Connector Elbow Hex Socket Plug Reducer Bushing Connector Plastic Tubing, 9 inch Venturi Assembly 3019229 FDR Handpiece and Controls (includes items 12--36) Head Cleaner Pork (includes items 1--11) 3019272 QTY 1 4 1 1 1 2 15 ft 1 2 1 1 2 1 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 13 of 32 Figure L Bung Cleaners Pork and Beef 3019274 Pork 3019325 Beef 3061352 Pork 3061386 Beef ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PART NO. 1012075 1050638 1059084 1019227 1071062 1055025 1055126 1019229 1004154 1059106 1012013 1059154 1059153 1019267 1071170 1073056 1016660 1016714 PART NAME Hose Clamp Hose Cuff Vacuum Hose Handle Tube Assembly Cap Flat Head Socket Screw Hex Head Screw Handle (pork/beef) Washer Steam Hose Hose Clamp Hose Cuff Vacuum Hose Handle Tube Assembly Cap Flat Head Socket Screw Sanitizer Housing, Pork Sanitizer Housing, Beef JARVIS 6239003.b QTY 1 2 10 ft 1 1 1 1 1/2 1/2 1 2 2 10 ft 1 1 1 1 ® ITEM 18 19 20 21 22 PART NO. 1055604 1013297 1013315 1071065 1071172 1002524 1002558 1050873 PART NAME Hex Head Screw Brush Retaining Ring, Pork Brush Retaining Ring, Beef Brush, Pork Brush, Beef Sanitizer Cover, Pork Sanitizer Cover, Beef Street Elbow 3019274 Bung Cleaner, 2 in (includes items 1--9) 3019325 Bung Cleaner, 4.5 in (includes items 7--16) 3061352 3061386 QTY 8 1 1 1 1 Sanitizer (includes item 17--21) Pork Beef PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 14 of 32 Figure M Steam Cleaner and Acid Dispenser Control Circuit 3022108 Handpiece Assembly ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 PART NO. 1059105 1059104 3019317 1071173 1071160 1051291 1071261 1051292 1050757 1050898 1050529 1050897 1007398 3061401 1011175 1059106 1051169 1034060 1050016 1022066 PART NAME Hose Cuff Vacuum Hose Handle and Swivel Assy Handle Assembly, 8 inch Handle Assembly, 4 inch Connector, Tube to Pipe Plastic Tubing, 6 inch Pipe Coupling Nozzle Elbow, 45 Degree Pipe Tee Connector Hex Jam Nut Tube Assembly Connector Steam Hose Connector Elbow Air Filter Hex Nipple Air Regulator JARVIS 6239003.b QTY 2 10 ft 1 1 1 2 1 1 2 1 1 1 1 1 1 2 2 1 2 2 ® ITEM 21 22 23 24 25 26 27 28 29 PART NO. 1050309 1050027 1051195 1051083 1022343 1050071 3022084 1011175 1025049 1061253 1061459 1061835 PART NAME Street “Tee” Street Elbow Vent Fitting Connector Elbow Air Valve Reducer Bushing Venturi Assembly Connector Air Pressure Gauge Tubing, .25 OD, Yellow Tubing, .25 OD, 16 ft, Yellow Tubing, .25 OD, 9 ft, Clear 3019316 Handpiece Assy, 4 inch (includes items 1--3, 5--16) Handpiece Assy, 8 inch (includes items 1--4, 6--16) Acid Pump Assembly (not shown) with Control Circuit (items 17--29) 3019334 3008401 QTY 1 1 1 2 1 1 1 2 1 15 ft 1 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 15 of 32 Figure N SR--1 Brain Sucker 3019280 Figure O TS--1 Tail Cleaner 3019258 ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 PART NO. 1059104 1059105 3019337 3061396 1007003 1035012 1014092 1039079 1035309 1018070 1010286 1016740 1035279 1051118 1019270 1004049 1027091 1061083 1012122 1059123 1059122 1051007 1051115 1061448 1061449 1051161 PART NAME Vacuum Hose Cuff Connector Assembly Tube Assembly Hex Nut O--ring Spring Plunger with item 13 O--ring Trigger Lever Pivot Pin Cartridge Housing O--ring Elbow Handle Lock Washer Stud Plastic Tubing, 10 ft Hose Clamp Hose Cuff Vacuum Hose, 10 ft Quick Connect Plug Connector Plastic Tubing, Red Plastic Tubing, Blue Connector Elbow JARVIS 6239003.b QTY 10 ft 2 1 1 4 1 1 1 2 1 1 1 1 1 1 4 4 1 2 2 1 1 2 16 ft 16 ft 2 ® ITEM 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 PART NO. 1019192 1004073 1055046 1035012 1022211 1018020 1010235 1054153 1055134 1024035 1012033 1004003 3019257 1059106 1022281 1051063 1051069 PART NAME “D” Handle Split Lock Washer Hex Head Screw O--ring Trigger Valve with item 29 Trigger Lever Pivot Pin Threaded Plug Socket Head Cap Screw Trigger Guard Trigger Clamp Half Lock Washer Tail Cleaner Handpiece Steam/Water Hose Water/Steam Valve Street “Tee” Air Bleed Fitting QTY 1 1 1 2 1 1 1 1 2 1 1 1 1 1 1 1 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and table Model CVS--1 Vacuum Cleaning System page 16 of 32 Figure P Vacuum Pump Assembly Style 1 15 - 60 hp JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and table Model CVS--1 Vacuum Cleaning System page 17 of 32 Figure Q Vacuum Pump Assembly Style 1 75 - 200 hp JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and table Model CVS--1 Vacuum Cleaning System page 18 of 32 Figure R Vacuum Pump Assembly (Kaeser) 15 - 100 hp JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com Model CVS--1 Vacuum Cleaning System page 19 of 32 Figure S Vacuum Pump Assembly (Jarvis) 15 - 100 hp JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 20 of 32 Figure T Gauge Panel Assembly 3025013 ITEM 1 2 3 4 5 6 7 8 9 JARVIS 6239003.b PART NO. 1024185 1032462 1025038 1025037 1017164 1055735 1025039 1055296 1007003 ® PART NAME Panel Guard Mounting Plate Pressure Gauge Vacuum Gauge Name Label Cheese Head Screw Temperature Gauge Hex Head Screw Hex Nut QTY 1 1 1 1 1 4 1 4 4 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 21 of 32 Vacuum Filter Assembly 80 Gallon Tank 3061209 Figure U Sediment Tank and Vacuum Filter Assemblies 24 inch Cyclone Tank 3061300 * not used in current tanks ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 PART NO. 1017276 1017275 1055955 1018138 1050682 1017072 1002381 3006009 1050784 1050786 3022065 1061724 1061662 1022217* 3022096 15 16 17 18 19 1002460 1035627 1061893 1002461 1035628 PART NAME “OUT” Label “IN” Label Socket Hd Shoulder Screw Lever Arm Pipe Cap Caution Label Tank Cover with Gasket Clamping Knob Pipe Coupling Inlet Deflector Float Valve Assy with Cup Cup (with item 11) Tank, 80 Gallons Ball Valve, 3 inch tanks Gravity Dump, 6 inch tanks (see page 24) Tank Cover Cover Gasket 24 inch Cyclone Tank Tank Cover Cover Gasket JARVIS 6239003.b 54 inch Cyclone Tank 3061304 36 inch Cyclone Tank 3061301 QTY 1 1 2 1 1 1 1 1 1 1 1 1 1 1 ITEM 20 21 22 23 24 25 1 1 1 1 1 ® PART NO. 1061894 1002471 1035629 1061918 3034009 3034022 3034016 3034023 3034013 3034024 3034010 3034015 3034017 1034053 1034075 1034070 1034065 1034074 1034076 1034079 1034080 1034081 PART NAME QTY 36 inch Cyclone Tank 1 Tank Cover 1 Cover Gasket 1 54 inch Cyclone Tank 1 Vac Filter Assy, 4 inch 1 Vac Filter Assy, 4 inch, SST Vac Filter Assy, 5 inch 1 Vac Filter Assy, 5 inch, SST Vac Filter Assy, 6 inch 1 Vac Filter Assy, 6 inch SST Vac Filter Assy, 8 in Flange 1 Vac Filter Assy, 10 in Flange 1 Vac Filter Assy, 12 in Flange 1 Filter Element with 3034009 1 Filter Element with 3034016 1 Filter Element with 3034013 1 Filter Element with 3034010 1 Filter Element with 3034015 1 Filter Element with 3034017 2 Filter Element with 3034022 1 Filter Element with 3034023 1 Filter Element with 3034024 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 22 of 32 Figure V Dump Valve Assembly 3022091 ITEM 1 2 3 4 5 6 7 8 9 PART NO. 1032723 1032590 1035616 1029400 1022271 1029401 1004073 1055286 1032589 PART NAME Guard Support Bracket Male Pipe Plate Seal Spacer Body Spacer Split Lock Washer Hex Head Screw Female Pipe Plate JARVIS 6239003.b QTY 4 1 4 4 1 8 8 8 1 ® ITEM 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 PART NO. 1061919 1024257 1055990 1017061 1055274 1010491 1011374 1007362 1013246 1051184 1051115 1008252 1007244 1024296 1004001 1055334 1042512 1029402 1007297 3022089 3022091 PART NAME Gate Guard Hex Head Screw Name Label Drive Screw Pin Yoke Jam Nut External Retaining Ring Elbow Fitting Fitting Air Cylinder Nut Guard Washer Hex Head Screw Bracket Spacer Lock Nut QTY 2 2 8 1 4 2 2 2 2 2 2 2 2 1 4 4 2 8 8 Dump Valve Assembly with Control Box, 115 V Dump Valve Assy without Control Box PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 23 of 32 Figure W Control Box Assembly ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 PART NO. 1055331 1004022 1022245 1063872 1051184 1051188 1051115 1007404 1063362 1063526 1063867 1063494 1011240 1001151 1007278 1004211 1063363 1063496 1063455 1063353 PART NAME QTY Hex Head Screw 4 Washer 7 Valve without Solenoid Coil 2 Solenoid Coil, 115 V 2 Elbow Fitting, Port 1 1 Exhaust Muffler, Ports 3 & 5 2 Fitting, Ports 2 and 4 4 Hex Lock Nut 4 End Clamp Terminal 1 Suppressor 2 Controller Module 1 Grey Terminal Block 2 Strain Relief Connector 3 Cord 6 ft Locking Nut 3 Sealing Washer 3 Terminal Marker 4 Yellow/Green Terminal Block 2 Fuse Terminal Block 1 Fuse 1 JARVIS 6239003.b ® ITEM 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 - 3063267 - 115 V PART NO. 1063456 1034014 1007355 1004206 1051001 1051185 1055197 1042300 1055010 1032536 1016571 1017012 1017085 1017338 1051190 1051188 1055021 1032537 1061449 PART NAME QTY Terminal Marker 2 Air Filter 1 Hex Lock Nut 2 Washer 2 Quick Connect Plug 1 Fitting (far side) 1 Socket Head Cap Screw 2 Terminal Rail 1 Pan Head Screw 3 Mounting Plate 1 Enclosure 1 Ground Warning Label 1 Electrical Danger Label 1 Connection Diagram Label 1 “T” Fitting, Port 1 1 Exhaust Muffler, Ports 3 & 5 2 Socket Head Cap Screw 4 Control Mounting Plate 1 Blue Plastic Tubing 12 ft PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 24 of 32 Figure X Gravity Auto Dump Valve Assembly -- 3022096 ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 PART NO. 1071034 1028135 1007043 1055326 1036316 1032631 1035644 1032632 1055271 1012136 1055417 1004207 1007252 1036315 1007297 1055849 JARVIS 6239003.b ® PART NAME Counterweight Arm Hex Lock Nut Hex Head Screw Bushing Bottom Plate Gasket Top Plate Truss Head Screw Clamp Hex Head Screw Washer Hex Lock Nut Bushing Hex Lock Nut Socket Set Screw, Cup Pt. QTY 1 1 4 1 1 1 1 1 4 1 2 2 2 1 1 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com parts diagram and list Model CVS--1 Vacuum Cleaning System page 25 of 32 Figure Y Exhaust Air Temperature Interlock - 3063402 (115V) - 3063413 (230V) ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 PART NO. 1011365 1007369 1063390 1063825 1063537 1063762 1072152 1072151 1072246 1063363 1063496 1063494 1063495 1063896 1073099 1004226 1072089 1011248 1007249 1063889 1072142 PART NAME Cord Connector Locking Nut Fuse Terminal Block Terminal Marker Fuse, 115v Fuse, 230v Relay Socket Relay, 115v Relay, 230v Terminal Marker Green/Yellow Terminal Bl Grey Terminal Block Blue Terminal Block, 230v Bridge Bar Terminal Pan Head Screw Washer Terminal Rail Cord Connector Locking Nut Suppressor, 115v Suppressor, 230v JARVIS 6239003.b QTY 2 2 1 2 1 1 1 12 2 4 2 1 2 2 1 2 2 1 ® ITEM 16 17 18 19 20 21 22 23 24 25 26 27 PART NO. 1016742 1072153 1072247 1017436 1072154 1072155 1017085 1017437 1014444 1016743 1007303 1011364 1063592 3005040 3063401 3063396 3063433 PART NAME Electrical Enclosure Red Indicator Light, 115v Red Indicator Light, 230v Over Temperature Label Replacement Lens Replacement Lamp Danger Label, Electric Connection Diagram, 115v Connection Diagram, 230v Electrical Enclosure Locking Nut Cord Connector Terminal Strip, 1 pole Thermostat Switch Assy Junction Box Assembly Control Box Assy, 115v Control Box Assy, 230v QTY 1 1 1 1 1 1 1 1 1 1 2 1 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com specifications Model CVS--1 Vacuum Cleaning System SPECIFICATIONS Vacuum Pump Assembly Power / Air Flow 9.3 m3 / min 15 hp 328 ft3 / min 11 kW 3 20 hp 495 ft / min 15 kW 14 m3 / min 3 25 hp 577 ft / min 19 kW 16.3 m3 / min 30 hp 700 ft3 / min 22 kW 19.8 m3 / min 40 hp 864 ft3 / min 30 kW 24.5 m3 / min 50 hp 1000 ft3 / min 37 kW 28.3 m3 / min 60 hp 1312 ft3 / min 45 kW 37.2 m3 / min 75 hp 1540 ft3 / min 56 kW 43.6 m3 / min 100 hp 2000 ft3 / min 75 kW 56.6 m3 / min 85 m3 / min 150 hp 3000 ft3 / min 112 kW 3 200 hp 4000 ft / min 149 kW 113.3 m3 / min 200 hp 5000 ft3 / min 149 kW 141.6 m3 / min Overall Dimensions (l x w x h) see pages 16--19 Handpiece Hot Water Requirements (HS--1, HS--2 and TS--1) 3.5 gal / min 60 psi 180° F 13.2 L / min 4.1 bar 83° C Maximum Steam Requirements (CV Models only) 200 lb / hr at 30 psi 90 kg / hr at 2.1 kg / cm Operating Steam Pressure 17--30 psi 1.2--2.1 kg/cm2 Vacuum Requirements per Handpiece: HS Front or Rear Leg 1000 ft3 / min at 14 in Hg 28.3 m3 / min at 356 mm Hg FV Floor Cleaner TS--1 Tail Cleaner 575 ft3 / min at 14 in Hg 16.3 m3 / min at 356 mm Hg SHC Sp. Cord Remover 328 ft3/min @ 14 in Hg 9.3 m3 / min at 356 mm Hg SR--1 Brain Sucker 300 ft3 / min at 14 in Hg BCC Bung Cleaner 8.5 m3 / min at 356 mm Hg CV Carcass Cleaner 140 ft3 / min at 14 in Hg CV Spin. Cd. Rem 3.96 m3 / min at 356 mm Hg SR Spinal Cord Rem. FDR Fecal Debris Rem. Head Cleaner Operating Vacuum Pressure 7--14 in Hg 37--47 kpa Control Handles (HS--1, HS--2 and TS--1) Air / Single / Trigger 100 psi 6.8 bar Capacity 390 carcasses / hour HS--1 27 in 686 mm HS--2 26.5 in 673 mm CV 13 in 330 mm Overall Dimensions (l x w x h) SR 12 in 305 mm FV 58 in 1473 mm JARVIS 6239003.b ® page 26 of 32 Weight HS--1 HS--2 CV SR FV Filters 3034009 4 in Size (∅ x h) Weight 3034016 5 in Size (∅ x h) Weight 3034013 6 in Size (∅ x h) Weight 3034010 8 in Size (∅ x h) Weight 3034015 10 in Size (∅ x h) Weight 3034017 12 in Size (∅ x h) Weight 12 lbs 16 lbs 3.5 lbs 1.15 lbs 12 lbs 520 ft3 / min 12 x 27.1 in. 55 lb 800 ft3 / min 16 x 28.1 in 82 lb 1100 ft3 / min 16 x 29.1 in 95 lb 2000 ft3 / min 20 x 38 in 185 lb 3000 ft3 / min 24 x 57.5 in 380 lb 5000 ft3 / min 24 x 69.5 in 465 lb 5.4 kg 7.3 kg 1.6 kg 0.52 kg 5.4 kg 14.7 m3 / min 30.5 x 68.8 cm 24.9 kg 22.7 m3 / min 40.6 x 71.4 cm 37.2 kg 31.1 m3 / min 40.6 x 71.4 cm 43.1 kg 56.6 m3 / min 50.8 x 96.5 cm 83.9 kg 85 m3 / min 61 x 146.1 cm 172.4 kg 141.6 m3 / min 61 x 176.5 cm 210.9 kg Sediment Tank 3061209 3 in 350 ft3 / min 9.9 m3 / min Size (∅ x h) 23.8 x 66 in 60.3 x 167.6 cm Volume 80 gal 303 L Weight 210 lb 95 kg 3 3 28.3 m / min 3061300 6 in 1000 ft / min Size (∅ x h) 24 x 76.2 in 61 x 193.5 cm Volume 57.7 gal 218 L Weight 235 lb 107 kg 56.6 m3 / min 3061301 8 in 2000 ft3 / min Size (∅ x h) 36 x 84.2 in 91.4 x 213.9 cm Volume 137.8 gal 521.6 L Weight 550 lb 250 kg 3061304 14 in 4000 ft3 / min 113.3 m3 / min Size (∅ x h) 54 x 101.5 in 137.2 x cm Volume 357.3 gal 94.4 L Weight 950 lb 431 kg Overall Dimensions (l x w x h) see page 14 Auto Dump Valve Operating Voltage Weight 115 V, 1 phase, 60 Hz 102 lb, 46 kg for details see pages 22--23 PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com installation instructions Model CVS--1 Vacuum Cleaning System page 27 of 32 INSTALLATION INSTRUCTIONS ALWAYS DISCONNECT THE POWER SUPPLY IN ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT PROCEDURES (29 CFR 1910.147) BEFORE PERFORMING ANY MAINTENANCE OR REPAIRS. ALL WIRING MUST BE DONE IN ACCORDANCE WITH NATIONAL, STATE AND LOCAL ELECTRICAL CODES. Refer to system overview, Figure A on page 4, as a general guide for installing the central vacuum cleaning system. 1 VACUUM PUMP ASSEMBLY Refer to Figure S, page 19 for referenced items. 1.1 Locate the equipment in a clean, dry area and provide adequate space on all sides of the unit for cooling and accessibility for maintenance of all components. 1.2 The unit must be securely bolted to a solid, stable floor or housekeeping pad utilizing all of the mounting holes provided in the unit frame. Shims or spacers are recommended to bring the unit frame or supports level with the mounting area. The objective is to make the unit frame tight and level on the mounting surface to absorb and eliminate transient vibrations. There should not be any overhang of the unit frame to the mounting surface. 1.3 All connection piping must be self supporting to prevent stressing of the vacuum pump. Where a flexible connection is not practical, the weight of the rigid connection must be separately supported. 1.4 The size of the discharge line must never be less than the equipment porting. 1.5 Discharge lines must be contained to a point of termination out of doors with the discharge line turned down and screened. 1.6 All system piping must be cleaned internally before connecting to the vacuum pump. 1.7 The drive coupling or pulleys must be checked for proper alignment. Misalignment most often occurs during shipment and while the equipment is being set in place. It is also required to rotate the vacuum pump by hand to check for free turning. Do not operate the JARVIS 6239003.b ® equipment electrically until this step has been completed. 1.8 Check oil level in vacuum pump. The unit is shipped with the proper amount of break--in oil, but you must check to insure that nothing has spilled during transit. Permanent oil must be installed after 100 hours of run time. Refer to filling procedure, section 4, page 28. 1.9 Electrical service must be the same as motor nameplate data. 1.10 The exhaust air temperature switch must be tied into the vacuum pump starter circuit. If exhaust air exceeds 260° F (127° C) the pump must shut down. This interlock is provided to prevent a fire inside the discharge piping. Refer to Figure Y, page 25 for details of the installation. 1.11 Jog the vacuum pump motor (item 6) to insure correct rotation. 1.11.1 As viewed from the input shaft end of the vacuum pump (item 2), the correct rotation is counterclockwise. If the rotation is not correct, switch any two of the three electrical service lines coming into the motor (item 6). 1.12 While the pump is running, check that the vacuum relief valve (item 1) is set for the desired amount of vacuum. Refer to section 5, page 28. 2 REMOVING PROTECTIVE MATERIALS Note: The following procedures apply only in the case of a replacement vacuum pump. These procedures have already been implemented on all complete systems shipped from our factory. Note: Follow the safety directions of the solvent manufacturer. Note: Rotating components will cause severe injury in case of personal contact. Keep hands away from vacuum pump inlet and discharge ports. 2.1 The shaft extension is protected with rust inhibitor that can be removed with any standard solvent. 2.2 Vacuum pump inlet and outlet are temporarily capped to keep out dirt and other contaminants during shipment. These covers must be removed before start--up. PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com installation instructions Model CVS--1 Vacuum Cleaning System 2.3 The internal surfaces of all units are mist sprayed with a rust preventative to protect the vacuum pump during shipment. Remove this film before initial startup using a commercial safety solvent. Position the vacuum pump so that the inlet and discharge connections are in the vertical position (vertical airflow). Place a shallow pan on the under side of the unit. With the vacuum pump disconnected from power, spray the solvent in the top port while rotating the impellers by spinning the shaft manually. Continue this procedure until the unit is visibly clean. 3 CHECK LUBRICATION Note: Replacement vacuum pumps are shipped dry from the factory. Do not attempt to operate the vacuum pump before checking for proper lubrication. Permanent damage to the gears, bearings and seals will occur. 3.1 Shaft bearings at the gear end of the pump are splash lubricated by one or both gears. Shaft bearings at the drive end are lubricated by a slinger assembly. 4 FILLING PROCEDURE: Refer to Figure 1 below. 4.1 Use Jarvis Synthetic Gear Lubricant Oil, part number 1062033, in the vacuum pump. 4.2 Remove fill plugs or breathers (A) from both gear and drive end plates. Slowly add oil until oil appears in the oil sight glass (B). Bring oil level to center of sight glass. Replace fill plugs or breathers in their correct location. page 28 of 32 5 VACUUM RELIEF VALVE 5.1 A relief valve is used to protect against excessive vacuum conditions. The valve should be tested at initial startup to be sure it is adjusted to relieve at or below the vacuum pump’s maximum vacuum rating. Refer to the name plate on the vacuum relief valve or see table, Figure S on page 19. 6 VACUUM FILTER ASSEMBLY 6.1 Connect vacuum filter assembly with sediment tank and relief valve. Provide adequate space to access vacuum filter assembly for removing canister cover to inspect or replace filter element. 7 SEDIMENT TANK 7.1 Locate sediment tank over drain or provide piping to permit discharge to run freely into the appropriate drain. 7.2 Remove pipe cap (item 5, Figure U, page 21). Attach hot water hose and shut off valve (customer provided) to tangentially mounted inlet pipe. 8 STEAM SUPPLY 8.1 Provide a steam shutoff valve within access of the operator in case of piping or hose failure. 8.2 Install a filter in steam line with pressure gauges on both inlet and outlet sides (or a delta “p” gauge). Follow manufacturer’s installation instructions. 8.3 Install a steam pressure regulator (0--50 psi) after the steam filter. Figure 1 A = Breather B = Sight Glass C = Oil Drain JARVIS 6239003.b ® PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com installation and operation instructions Model CVS--1 Vacuum Cleaning System page 29 of 32 9 STEAM or HOT WATER / VACUUM HANDLE 11.2 An air regulator must be installed before the 9.1 Connect steam hoses (item 22, Figures D and E, page 7) between steam header and vacuum handpiece. 9.2 Attach hot water hose (supplied by customer) and vacuum hose assembly (items 10 and 11, Figure H, page 10 and/or items 26 and 27, Figure I, page 11) to hot water valve (item 4, Figure H, page 10 and/or item 21, Figure I, page 11). Connect hose (item 5, Figure H, page 10 and/or item 20, Figure I, page 11) between the hot water valve and Front Leg Hand Piece (item 8, Figure H, page 10) and/or the Rear Hock Hand Piece (item 24, Figure I, page 11). 10 AIR SUPPLY / HOCK CLEANERS 10.1 The air inlet pipe should be 3/8 inch diameter minimum. 10.2 An air regulator must be installed before the inlet to the triggers (item 27, Figure H, page 10 and/or item 19, Figure I, page 11). 10.3 The required compressed air supply is 100 psi (6.8 bar). 10.4 Attach blue plastic tubing (item 26, Figure H, page 10 and/or item 14, Figure I, page 11) from fitting (item 1, Figure H, page 10 and/or item 18, Figure I, page 11) to elbow fitting (item 12, Figure H, page 10 and/or item 13, Figure I, page 11) on ”D” handle (item 15, Figure H, page 10 and/or item 10, Figure I, page 11). 10.5 Attach red plastic tubing (item 14, Figure H, page 10 and/or item 17, Figure I, page 11) from elbow fitting (item 12, Figure H, page 10 and/or item 13, Figure I, page 11) on ”D” handle (item 15, Figure H, page 10 and/or item 10, Figure I, page 11) to fitting (item 1, Figure H, page 10 and/or item 18, Figure I, page 11) on street tee (item 2, Figure H, page 10 and/or item 22, Figure I, page 11) installed on hot water valve (item 4, Figure H, page 10 and/or item 21, Figure I, page 11). 11 AIR SUPPLY / AUTO DUMP VALVE. Refer to Figure W on page 23 for referenced items, unless noted otherwise. 11.1 The air inlet pipe should be 3/8 inch diameter minimum. JARVIS 6239003.b ® 11.3 11.4 11.5 11.6 11.7 inlet fitting (item 24) to the control box filter (item 21). The required compressed air supply is 100 psi (6.8 bar). Connect fitting (item 25) on control box filter (item 21) to ”T” fitting (item 34) on control valve “B” using blue plastic tubing provide with control box. Attach blue plastic tubing from ”T” fitting (item 34) control valve “B” to elbow fitting (item 5) control valve “A”. Attach blue plastic tubing from fittings (item 6) on port 4 of control valves “A” and “B” to fittings (item 20, Figure V, page 22) on air cylinders (item 21, Figure V, page 22). Attach blue plastic tubing from fittings (item 6) on port 2 of control valves “A” and “B” to elbow fittings (item 19, Figure V, page 22) on air cylinders (item 21, Figure V, page 16). OPERATION INSTRUCTIONS ALWAYS DISCONNECT THE POWER SUPPLY IN ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT PROCEDURES (29 CFR 1910.147) BEFORE PERFORMING ANY MAINTENANCE OR REPAIRS. Refer to Figures H and I on pages 10 and 11 for referenced items. 1 Each day before you begin operation, go through the following checklist: 1.1 Connect all air hoses. 1.2 Make sure that the compressed air supply is at the proper pressure (100 psi / 6.8 bar). 1.3 Start the vacuum pump. 1.4 Open the steam shut--off valve and adjust the pressure regulator for the desired steam pressure. 1.5 Make sure the models HS--1 and HS--2 are working correctly. Check for the correct operation of the trigger prior to use or daily. 1.5.1 Depress the trigger lever (item 18 or 5) and the hot water valve (item 4 or 21) should open. Release the trigger lever and the hot water valve should close. If the tool malfunctions, remove it from service and report the problem to your supervisor immediately. PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com operation and maintenance instructions Model CVS--1 Vacuum Cleaning System 2 Vacuuming procedure. 2.1 Place either the HS--1 front leg cleaner or the HS--2 rear hock cleaner around the front leg or rear hock of the carcass. 2.2 Depress the trigger lever (item 18 or 5) to begin the vacuuming procedure. 2.3 Release the trigger lever when the vacuuming procedure is completed. MAINTENANCE INSTRUCTIONS ALWAYS DISCONNECT THE POWER SUPPLY IN ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT PROCEDURES (29 CFR 1910.147) BEFORE PERFORMING ANY MAINTENANCE OR REPAIRS. IMPORTANT: SHUT OFF STEAM AND HOT WATER SUPPLY AND ALLOW THE COMPLETE SYSTEM TO COOL DOWN BEFORE PERFORMING ANY REPAIRS OR MAINTENANCE. HANDLE AND DISPOSE OF SOLVENTS AND WASTE IN ACCORDANCE WITH OSHA’S HAZARDOUS MATERIAL PROCEDURES (29 CFR 1910.120) AND NATIONAL AND STATE REGULATIONS. Note: Refer to safety precautions, section 10, page 31 before performing any system maintenance. Refer to vacuum pump trouble shooting, section 12, page 32 to diagnose vacuum pump problems. 1 DAILY: 1.1 Open the slide valves on bottom of sediment tank and drain the collected waste after each shift or as needed. 1.1.1 Rotate manual override screws on solenoid valves (item 3, Figure W, page 23). 1.2 Flush sediment tank with hot water. 1.2.1 Open hot water shut off valve and flush tank with slide valves open and vacuum pump off. 1.3 Check condition of steam, hot water and vacuum hoses and repair or replace as necessary. 2 WEEKLY: 2.1 Check for leaks around the vacuum pump (item 2, Figure S, page 19) as an indication that the oil level may have changed. 2.2 Open vacuum filter assembly and clean or replace filter element as necessary. 3 MONTHLY: JARVIS 6239003.b ® page 30 of 32 3.1 Check belt tension. Refer to section 7, drive reinstallation procedure. 3.2 Top off oil level in vacuum pump gearbox. Refer to section 4, filling procedure on page 28. 4 WHEN NECESSARY: 4.1 Renew steam filter element when pressure drop across filter exceeds manufacturer’s recommended delta “p”. Follow manufacturer’s recommendations for filter sterilization. 4.2 Change oil in vacuum pump gearbox at least every 1000 hours or more frequently if inspection so indicates. 4.3 Clean vacuum pump’s interior. 4.3.1 Refer to installation instructions, section 2.3 for proper cleaning procedure. WD--40 or Loctite non--flammable solvents are recommended. 5 “D” HANDLE DISASSEMBLY Refer to Figures H or I, page 10 or 11 for referenced items. 5.1 Remove hex head screw (item 13 or 11) and lock washers (item 24 and 25 or 6 and 7) to separate handle from either the HS--1 or HS--2. 5.2 Push out dowel pin (item 22 or 4) and lift away trigger lever (item 18 or 5). 5.3 Unscrew threaded plug (item 17 or 8) and gently grasp stem with pliers to remove valve (item 16 or 9) from handle. 5.4 Inspect all parts for wear and replace if necessary. 6 ”D” HANDLE ASSEMBLY 6.1 Reverse steps and procedures outlined in section 5. 7 DRIVE REINSTALLATION 7.1 Belt drives must be carefully aligned. Motor and vacuum pump pulleys must be parallel to each other and in the same plane within 0.03 inch / 0.8 mm. Belt tension should be carefully adjusted to the belt manufacturer’s recommendation using a belt tension gauge. Check tension frequently during the first day of operation. PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com maintenance instructions Model CVS--1 Vacuum Cleaning System page 31 of 32 8 GEAR AND BEARING END LUBRICATION 9.2 Always ensure all seats, gaskets, clamps and Note: Do not overfill. Overfilling may cause excessive heating of the gears and may damage the unit. Refer to Figure 1, page 28. 8.1 Jarvis Synthetic Gear Lubricant Oil, part number1062033, is formulated especially for positive displacement vacuum pump service to provide maximum vacuum pump protection at any temperature. 8.2 If not using Jarvis Synthetic Gear Lubricant Oil, use oils with rust and oxidation inhibitors, anti--foam additives and a viscosity of 1000 SUS at 100° F / 220 ISO at 40° C. 8.3 Add fresh oil as required to maintain proper level. Drain oil from oil drain plug. 9 AIR FILTERS AND FILTER SILENCERS Note: To ensure long vacuum pump life, it is extremely important to service the air filters. 9.1 Clean or change air filter at least once a week until a baseline can be established after your initial inspections. Servicing frequency of filter elements is not time predictable. JARVIS 6239003.b ® hose connections on the filter and inlet line are absolutely air tight. 9.3 Each time the filter is replaced, inspect vacuum pump’s interior for dirt. 10 SAFETY PRECAUTIONS 10.1 When operating unit or when performing vacuum pump maintenance, adhere to the following safety precautions: 10.1.1 Do not operate vacuum pump with open inlet or outlet port. 10.1.2 Do not exceed specified vacuum limitations. 10.1.3 Do not operate with belt guard or coupling shield removed. 10.1.4 The vacuum pump and vacuum pump discharge piping may be extremely hot and can cause skin burns on contact. 10.1.5 Prolonged exposure may require ear protection. 11 VACUUM PUMP TROUBLE SHOOTING 11.1 The trouble shooting chart appearing on page 32 is provided to quickly diagnose and fix problems associated with the vacuum pump. PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com maintenance instructions Model CVS--1 Vacuum Cleaning System page 32 of 32 VACUUM PUMP TROUBLE SHOOTING CHART PROBLEM Knocking POSSIBLE CAUSES SOLUTION 1. Unit out of time. 2. Distortion due to improper mounting or pipe strains. 3. Excessive pressure differential. 4. Worn gears. 5. Worn bearings. 1. Too much oil in gear case. 2. Too low operating speed. Excessive vacuum pump temperature Return unit to Jarvis for servicing. 1. Reduce oil level. 2. Check belts for tension and slippage. 3. Remove cause of obstruction. 4. Reduce pressure differential across the vacuum pump. 3. Clogged filter or muffler. 4. Excessive pressure differential. 5. Return unit to Jarvis for servicing. 5. Worn impeller clearances. Impeller end or tip drag 1. 2. 3. 4. Lack of volume 1. Slipping belts. 2. Worn clearances. 1. Tighten belts. 2. Return unit to Jarvis for servicing. 1. Improper lubrication. 1. Correct lubrication level. Replace dirty oil. 1. Head plate, gear case or drive cover vents plugged. 2. Worn seal. 1. Clean vents. Excessive bearing or gear wear Loss of oil Insufficient assembled clearances. Case or frame distortion. Excessive operating pressure. Excessive operating temperature. JARVIS 6239003.b ® Return unit to Jarvis for servicing. 2. Replace seals. PRODUCTS CORPORATION 33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926 UNITED STATES OF AMERICA TEL. 860--347--7271 E--MAIL. jarvis.products.corp@snet.net FAX. 860--347--6978 WWW. jarvisproducts.com