Joining of Copper and Copper Alloys

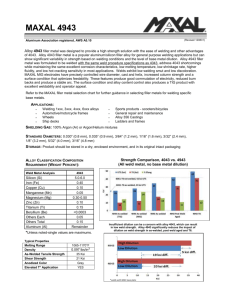

advertisement