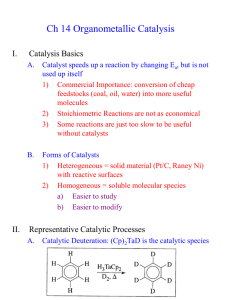

Metathesis and hydroformylation reactions in ionic

advertisement