Factsheet: The Mars Rover Curiosity - Development

advertisement

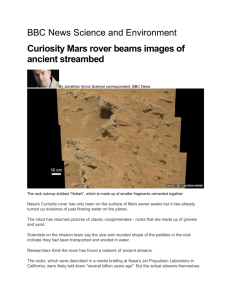

Siemens Energy Transition Dialog, June 3–11, 2013, Berlin Fact Sheet — the Mars Rover Curiosity: Development Software in Practice Introduction: • Last year, the Mars rover Curiosity flew through space at speeds of up to 112,000 km/h in a protective capsule on its way to the Red Planet. The capsule entered Mars’ atmosphere traveling at nearly 21,000 km/h and was then slowed down by retro rockets and a parachute to a very low speed. After that, the landing module hovered above the surface and gently lowered the rover to the ground. The complete maneuver was carried out fully automatically because it would have taken 14 minutes for command signals from Earth to reach Mars. • NASA scientists used software from Siemens to help create the Mars rover Curiosity. The specialists at NASA’s Jet Propulsion Lab employed PLM software from Siemens throughout the 900-kilogramn vehicle’s entire development process — from the initial concept to the simulation of the harsh conditions of outer space. The software enabled them to digitally design the rover, simulate complex sequences of movements, and assemble the vehicle virtually before a prototype was even built. For example, the forces to which the capsule and the rover would be exposed during the landing were simulated 8,000 times. When the capsule reached Mars in August 2012, the speed dropped from 21,000 km/h to less than 2 km/h in just seven minutes — the deceleration forces were correspondingly huge. The Mars rover within the context of Industry 4.0: • Industrial software from Siemens enables companies to manage their complete product development and manufacturing processes efficiently, economically, and intelligently. The processes involved range all the way from design and product planning to engineering, production, and service operations. As a result, industrial firms can deal more effectively with the increasing complexity of production processes. Siemens software is now utilized in many sectors, including the mechanical engineering, aerospace, and automotive industries. When combined with Siemens automation technology, the software systems can reduce time-to-market by up to 50 percent and also help to conserve resources and energy. Further information available at: http://www.siemens.com/innovation/apps/pof_microsite/_pof-fall2012/_html_en/virtual-worlds.html