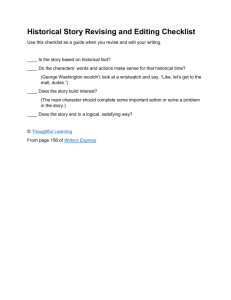

Water Vulnerability Assessment Checklists

advertisement