MC-MMAG5 Rev.1

4th Quarter, 2013

®

INTERNATIONAL MAGAZINE

GREAT DIGITAL EXPERIENCES

USING LAYAR APP.

SEE INSTRUCTIONS

ON PAGE 3

3D OR NOT 2B

PAGE 8

THE CANNES

EXPERIENCE

PAGE 22

NEXT GENERATION

REGENERATIVE

SOLUTIONS

PAGE 33

Greetings! Synergy between knowledge, products and procedures is fundamental to the MIS

vision. The articles, interviews and product reviews in this issue of the MNews clearly represent

that vision, and also bring to light our continued investment in technology as a precondition for

growth and innovation. For all those who attended our Global Conference in Cannes, France

this June, (and there were a lot of you), the MNews offers a recap of the event; characterized

by a high academic level, networking, recreation and fun. Product articles include the MGUIDE

MORE; increased diagnostic accuracy in our virtual dental implant planning and guided

implantology system, the expanded 4BONE brand; now an entire family of regenerative

biomaterial solutions, the C1 Narrow implant and many more exciting products. Our MIS

distributor showcase reveals what traits are common to successful business people and

explores the history and ongoing global educational programs of the Esparza Training Center

network in South America. In addition you’ll find an in-depth interview with a highly respected

KOL and pioneer in immediate loading and placement of implants; giving you a glimpse of

his vision for the future, plus many more articles we’re sure you’ll find useful and enjoyable.

MIS is committed to the continued expansion of our product range, bettering the processes by

which they are developed and produced; increasing our services

and the choices and flexibility in treatment options we can offer our

customers. To make it simple, we strive to boost quality, efficiency

and profitability for our customers worldwide.

Happy reading!

Idan Kleifeld

CEO, MIS Implants

Technologies Ltd.

04 Ride to success

08

3D or not 2B

the MIS portfolio of products

superstars

22

16

13 New in

Meet MIS distributor

The Cannes experience

27 A vision

for the future 33 Next generation regenerative solutions

38

Winners of MIS clinical case competition

It’s a great app 46 Upcoming events

© 2013 MIS Corporation. All rights reserved.

42

INTERACTIVE PRINT

Scan QR code to download the

free LAYAR augmented reality

app. Find the pages with this

symbol, scan and enjoy.

EVENT

RIDE TO

SUCCESS...

MAKE IT

SIMPLE

A SURPRISE PARTNERSHIP:

MIS IMPLANTS & PORSCHE

MIS-Implants Technologies Ltd. embodies

a deep commitment to creating innovative

yet simple solutions and products aimed

at improving dental implantology. MIS also

promotes professional and social events

on a global scale to encourage networking,

knowledge sharing and moral-building.

Such was the MIS Day in Portugal.

The event took place in two picturesque

port cities: Lisbon and Oporto. MIS

presented international speakers on a

variety of implantology topics, including

general advice to help doctors achieve their

professional and personal goals. Featured

speakers were Moshe Goldstein DMD,

specialist in periodontology, and Federico

4 MNEWS 4th Quarter, 2013

Hernandez-Alfaro MD. DDS. PhD. Feboms,

specializing in Oral and Maxillofacial

Surgery. Subjects included “Oral Implants

in Potentially Problematic Sites-Surgical

Options for Optimal Restorative Results”

and “Reconstructive surgery in oral

implantology - What have we learned?”.

What made the MIS DAY really special

was the inclusion of speakers from one

of the most prestigious and inventive

automotive brands, Porsche. The pairing

up of MIS-Implants with Porsche for this

event was a big surprise, however, not really

that surprising when you consider what

they have in common; both sharing core

principles of quality, accuracy, innovative

6 MNEWS 4th Quarter, 2013

The idea for this special joint event was inspired by MIS

and heartily welcomed by the automobile giant Porsche.

The purpose was to not only provide a scientific overview

for dental implantology professionals, but to provide a

platform for interactive socializing and the fostering of

an atmosphere of cooperation and friendship amongst

all participants. As explained by Ms. Cristina Antas da

Cunha, Director of Marketing and Sales at MIS Portugal:

“We wanted to create a unique event that was different

and stimulating, especially in light of the many challenges

facing the dental implants industry today. An event

that encourages energetic, creative thinking as a way

of problem solving; showing doctors the positive and

enthusiastic reaction to difficult situations and how to

do the best with the resources at hand. We succeeded

through innovative and motivating activities, and with the

aid of internationally recognized speakers.”

The concept of quality and simplicity through advanced

engineering are highly prized at MIS. Mr. Doron Peretz,

Senior VP of Marketing and Product Development at MIS

Implants Technologies explains. “As with many well-known

brands in all fields, our approach at MIS revolves around the

design of a simpler solution, in this case implant systems.

A good example of MIS simplicity, quality and safety, is the

C1 implant, with its conical connection and dual stability

mechanism. It provides primary stability in the collar of the

implant and secondary stability in the apical part of the

implant, along

wi th o the r

components

that provide

a simple

solution used

with CAD/CAM

based titanium

to zirconia

interfaces.”

M r. Pe r e t z

continues.

“With a view

towards reducing

the investment in

quality and service,

MIS has introduced

surgical kits that are

simpler to use, assisting

dentists with clinical

procedures. What if in the future

you have the proper drill for each

implant, always sharp, clean and

safe? The dentist’s success rate increases

dramatically. Even if it takes a few more years to

accomplish, this concept depends on simplifying

the surgical procedure (not the implant itself), from

packaging, drilling, suture, graft, etc., including all

the appropriate safety and quality testing.”

Sharing a unique perspective on Implantology that he

created and developed at the School of Dental Medicine

at the Hadassah-Hebrew University Medical Center, in

Jerusalem, Dr. Moshe Goldstein, President of Europerio

2012, contributed to the event from a scientific perspective.

“Function, comfort and aesthetics are our daily goals, and

are achieved based on a step-by-step treatment plan

for every kind of implant case, from the simple to the

complex.” This was exactly what Dr. Goldstein presented

in his informative lecture and personal surgery videos.

Dr. Goldstein understands the importance of keeping up

with updates in the development of graft or regenerative

materials, guided surgery techniques, CAD/CAM, and other

restorative components newly developed in the industry.

In Oporto, Federico Hernandez-Alfaro MD. DDS. PhD.,

President of the Department of Oral and Maxillofacial

Surgery at the Medical Center of Teknon, Spain, and Head

of the Program of Dental Implantology at the International

University, lectured about developments in reconstructive

surgery, implant dentistry and the learning process that

led us to present day levels of expertise. Participants in

Oporto also attended a lecture by Dr. Nachum Samet, VP

of R&D at MIS Implants. Dr. Samet focused on Implant

Osteotomy, Stability, factors that have been largely achieved

with MIS Implants Technologies: The SEVEN implant

internal connection and the C1 conical connection. He

focused on the meaning behind the MIS motto: Make

it Simple, first discussed by Mr. Doron Peretz in Lisbon.

“The simplicity of the surgical procedure is built-in to the

C1 implant, whose standard package includes the ability

for immediate loading, and a specially designed final drill

for better clinical outcomes.”

Over 400 implant professionals participated in the MIS

Day event - the first of a series, highlighting scientific

research, cultural experiences, sporting events and

numerous other activities designed to educate, update,

motivate and surprise. The MIS Day event in Portugal

also made us realize how much unites MIS Implants

with Porsche. It was a stunning success enjoyed by all,

owing to the efforts of organizers and participants alike,

and is sure to be repeated in the coming years.

‘‘

Function, comfort

and aesthetics are our daily

goals, and are achieved

based on a step-by-step

treatment plan for every kind

of implant case, from the

simple to the complex.

‘‘

design and attention to safety. Porsche representatives

presented a fascinating insight into this iconic automotive

brand, resulting in an important knowledge exchange

and some truly unforgettable moments.

7 MNEWS 4th Quarter, 2013

8 MNEWS 4th Quarter, 2013

When Virtual Becomes Reality

3D OR NOT 2B...

Mr. Liron Moshe

MIS MGUIDE MORE

Product Manager

The MGUIDE MORE is an advanced virtual implant planning and

guided implantology system that has been developed by MIS to

accurately transform DICOM data into 2D and 3D images that depict

real cases in a virtual environment; enabling real-time 2D and 3D

visualization for perfect implant planning. The MGUIDE system is

a timesaving measuring and diagnostic tool featuring user friendly

software, and incorporates the production of a fully validated drilling

template for a minimally invasive surgery when indicated, assuring

accurate guided implantation with predictable prosthetic outcomes.

The MGUIDE MORE offers flexible prosthetic-driven planning that

can be done either by the clinician, using our simplified stateof-the-art MGUIDE software, or through our worldwide network

of MCENTER facilities. Available in over 20 countries and five

languages, the MCENTERS are full-service technical support and

guidance facilities. Implantology professionals using the MGUIDE

software become members of an important online information

hub that connects all software users; doctors, dental laboratories,

periodontists, prosthodontists and the MCENTER. MGUIDE

software users can share cases, take part in demonstrations,

initiate discussions or consultations. They can also use a

remote access feature that allows direct connection to another

member’s computer to share in the MGUIDE planning process.

How does the MGUIDE process begin? First a single patient Cone

Beam CT scan is done. The DICOM data is then uploaded for

a 3D clinical evaluation. Next comes the implant planning and

template design stage. Integration of a scanned wax-up and stone

models enable virtual top-down planning as well as the template

design. Then the stereo-lithographic templates are produced. These

open wire-frame templates are made using advanced 3D printing

technologies to ensure optimum fit. Now the guided surgery can

be performed. Restoration can be done via immediate provisional

prosthetic solutions that have been produced in advance using

MGUIDE prosthetic tools available for laboratory technicians.

There are many clear advantages to the open wire-frame design

of the MGUIDE MORE templates. It allows an open field of view

during surgery, where anesthesia and irrigation are accessible

from all angles without removing the template. Raised flap surgery

can also be more easily performed. The template is constructed

from a strong, durable biocompatible material and the 3D CAD/

CAM design ensures the highest level of accuracy. The lightweight

template design is an added benefit for patient comfort as well.

The MGUIDE MORE surgical kit not only enhances accuracy

and safety for a worry-free guided procedure, it also

simplifies the implantology process by eliminating the

need for traditional guidance keys. Specially designed

sleeves and drills stop at the precise position and depth

planned, freeing-up hands and saving valuable time.

Many guided implantology systems today still require

conventional techniques, often compromising on efficiency

or accuracy. The MGUIDE MORE is different. It has been

specially engineered to enable doctors and clinicians

to deliver a more accurate and streamlined minimally

invasive implant placement and restoration procedure,

resulting in less chair time and fewer patient appointments.

10 MNEWS 4th Quarter, 2013

MGUIDE Surgical Kits for

the SEVEN implant and 3D

printed surgical template

NEW IN THE

MIS PORTFOLIO

OF PRODUCTS

MIS CONTINUES TO INTRODUCE NEW PRODUCTS AND EXPAND EXISTING

PRODUCT LINES WITH THE AIM OF MAKING DENTAL IMPLANTOLOGY PROCESSES

SAFER, EASIER AND SIMPLER. WE HAVE A GENUINE COMMITMENT TO

INTRODUCING NEW SOLUTIONS AND TECHNOLOGIES PERFECTLY MATCHED

TO THE NEEDS OF IMPLANT PROFESSIONALS WORLDWIDE.

13 MNEWS 4th Quarter, 2013

Ti-BASE: Titanium base

connecting customized

abutments to MIS

implants

The Ti-Base abutments are MIS Titanium base units for CAD/CAM systems allowing the production of custom ceramic

abutments for a wide range of individualized solutions and greater compatibility to specific site requirements. Two

categories of Titanium Base abutments are available; for single unit restorations – with an anti-rotational mechanism

and a full implant-abutment connection, and for multiple-unit restorations – without an anti-rotation mechanism and with

a shortened implant-abutment connection. Both come in Standard, Narrow and Wide diameter sizes.

The C1 Narrow:

Implant and prosthetic

components

The C1 implant system is the result of an extensive research and development process that offers a unique combination of

surgical and restorative benefits. The C1 Narrow has a 3.30mm diameter and comes in lengths of 10mm, 11.50mm, 13mm

and 16mm. The narrow platform is suitable for use on narrow ridges and between closely spaced teeth or implants. The C1

Narrow features a unique conical connection, with a 4-position anti-rotational index. This enables thicker walls at the neck area,

resulting in a 3.3mm implant that is equivalent mechanically to 3.75 internal hex implants. The new implant also incorporates

the MIS dual stability mechanism (DSM) by design. When placed in full bone, the single-use final drill (supplied with each

implant) creates an osteotomy that generates mild compression at the coronal third of the implant, ensuring high initial stability,

while allowing rapid osseointegration in the apical third. This advanced technology combines the benefits of high primary

mechanical stability with an accelerated osseointegration, achieving rapid biological stability.

14 MNEWS 4th Quarter, 2013

Zirconia abutments

The new zirconia abutments are biocompatible, customizable and have superior strength characteristics. They combine

the esthetic benefit of zirconia, with the accuracy, strength and long-term stability of a titanium-to-titanium connection

between the implant and the abutment. The zirconia abutments are constructed for incisors (interior esthetic zone) and for

pre-molars (posterior zone). The titanium base comes in a non-reflective gold finish for best esthetic results. Two titaniumzirconia abutment options are available: Non-cemented and Pre-cemented. Pre-cemented zirconia abutments come as

a ready-to-use single units, manufactured from an anatomically designed zirconia component that is pre-cemented to

a titanium base. Modification can be made by reduction only. Single unit pre-cemented abutments are available in predesigned shapes for incisors and premolars.

OT EQUATOR:

Overdenture

solutions

The OT Equators are low-profile overdenture and removable denture attachments that offer a variety of retentive solutions.

With a functional height of 1.7mm, and a 2.5 diameter engagement area, it is ideal in cases of space limitations. Each

abutment is supplied with a metal housing and five retentive nylon inserts; allowing for a wide range of retentive options.

OT Equators are available for all MIS connection types and platform sizes, and in gingival heights of between 1-5mm.

The OT Equators are the smallest attachment system on the market, and are made under license at MIS to ensure

optimum accuracy at the implant-abutment connection. The titanium-nitride coating offers exceptional resistance to

wear and ensures long-term continuous functionality.

15 MNEWS 4th Quarter, 2013

UNDER THE

POTLIGHT

Ms. Claudia P. Esparza

and Mr. Samy Akerman

MEET MIS

DISTRIBUTOR

SUPERSTARS

Claudia P. Esparza, DDS, MBA and

Samy Akerman, DDS, operating MIS

Implants S.A.S in Colombia, Venezuela,

Ecuador and Mexico.

MIS is very proud of the high level of dedication

and professionalism that all our business

partners, distributors and sales reps provide

to our customers. With a world-class distributor

network in almost 70 locations spanning

16 MNEWS 4th Quarter, 2013

5 continents, it wasn’t an easy task to select

a single outstanding candidate to showcase

for the current issue of the MNEWS.

What Characteristics Make Up

a Superstar?

Motivated with MIS from

the Start...

to dentists that we can provide them with

substantial added value: Quality, customer

support and educational strategies.

A competitive nature is common to most

successful business people, regardless of

their area of expertise or cultural background.

Whether in games, sports, or deal making,

these people truly want to win; and are

prepared to make greater sacrifices, work

harder and learn every complexity of their

industry in order to do it.

In 2003, when we first began, the field

of implant dentistry in our country was

very weak. Amongst an economically

disadvantaged population, there was little

demand for treatments. A few dental implant

companies did exist, however most were

unable to offer an appropriate infrastructure,

logistics or reliable service. Also, there

were very few trained clinicians capable

of providing predictable treatments. We

were motivated to become a distributor

with MIS from the start; providing a great

product and excellent service.

Competition is a challenge, like with most

businesses in any industry. There’s a famous

saying: “Imitation is the sincerest form of

flattery”. There are companies out there

telling customers that they are MIS but

selling cheaper implants. MIS has earned

a good name, that’s why these competitors

want to capitalize on it, or even spread

false rumors to discredit us. We need to

maintain excellent marketing exposure to

neutralize these kinds of tactics. We also

face competition from the world’s largest

implant company, who has a strong market

presence, especially locally though their

lecture circuits etc.

Typically, effective sales and marketing

people are optimistic and upbeat. They

have their down days, sure, yet they

consistently bring a positive outlook to the

table. Enthusiasm is not only refreshing, it’s

contagious. Business may be serious and

demanding but a positive attitude always

helps in building profitable relationships.

Good sales and marketing people are

also good teachers. They understand the

importance of investing time in making

their customers more knowledgeable and

informed about products, processes and

technologies. They desire to bring real value

to their business relationships by building

a strong professional reputation through

rock-solid knowledge sharing.

Furthermore, we were immediately inspired

after our first meeting with Mr. Doron

Peretz, Senior VP Marketing and Product

Development. He is such a friendly, smart

and confident man, who offered great

encouragement in our efforts to start the

business. Then, after getting to know the

rest of the people at MIS, we knew without

a doubt, we were in the right place at the

right time. Alongside MIS, we have grown

both personally and professionally, and

are confident that the future holds many

shared opportunities for us.

Steadily Branching Out for

10 Years...

MIS Implants S.A.S Partners

Claudia and Samy are Pleased

to Tell Their Story:

Dentistry Became Our

Passion...

Since I was a kid, explains Claudia, I

was attracted to social services, and later

developed a deeper interest in health

sciences. At university, although I liked

medicine, I studied dentistry; which has

become my passion. As much as I have

loved practicing dentistry over the years, I

have been steadily moving from the clinical

field into the management and educational

arena, which I find very rewarding. Each and

every day is filled with wonderful experiences

and professional achievements. Samy on

the other hand, says that he first wanted

to be a doctor. But before graduating from

university realized he really didn’t want to

spend his life inside of a hospital. It was at

that point he decided to go into dentistry;

continuing in the medical field without being

confined to a hospital. Now, he enjoys the

best of both worlds.

18 MNEWS 4th Quarter, 2013

We’ve been in business since 2003, starting

here in Colombia, and steadily branching

out in South America to include Venezuela

and Ecuador, so we have been in the

Latin American market for ten years. We

now also operate in Mexico. We have

over 100 staff members in our regional

offices and another 100 affiliates working

for us. The owners are: In Colombia and

Ecuador; partners Claudia Esparza, Sammy

Akerman and Morris Benisty. In Venezuela,

our associates are Adriana, Veronica and

Juan Carlos Tejeira; and in Mexico we have

joined with Dr. Samuel Bukrinsky and Dr.

Edgar Hernandez.

Unfair Competition & Other

Challenges...

Latin America generally has a lower

income population compared with the

US or Europe, and dental implants and

treatments anywhere in the world are not

cheap. Product pricing is a critical issue

for us. In order to sell more and grow our

business, we not only need to keep prices

competitive, we must also make it very clear

The Keys to Our Success...

Our Company has grown step-by-step,

based on principles of integrity and

customer satisfaction. We promote open

communication with our sales staff, such as

frequent departmental meetings to discuss

difficulties and challenges. It takes time to

get to know our market and the customers.

We encourage a creative outlook and a

commitment to building strong personal

relationships. We tell our team: it’s not a

matter of making a sale, the key to success

is in developing loyalty and trust; creating a

true partnership with our customers. If you

provide excellence in both product training

and service, then everything else seems

to fall into place more easily - making it

simple. Through our independent academic

organization, Esparza Enclosed, we work

with a passion teaching dentists the most

advanced techniques in diagnosis, treatment

planning and surgical and prosthodontic

procedures.

Although there’s no magic formula for

success, we have made great progress

through an important mixture of ’good sense’

practices to achieve our business goals

which include: Having a great product with

a good ‘quality to price’ ratio, investment

in aggressive marketing campaigns,

maintaining a broad and comprehensive

stock to give customers great service,

providing top-class education and practical

training to dentists in alliance with our

distribution business, cultivating personal

relationships with university leaders, dental

clinics and public organizations, sponsoring

of our annual event; which has become

one of the largest dental implant industry

events in Colombia, and last but not least

– hard work!

Esparza Enclosed offices &

training center

Esparza Enclosed

Education…

Esparza Enclosed is a Training Center in

Implant Dentistry and Dental Continuing

Education. It is a Foundation offering clinical

courses that provide good quality treatment

to low income patients free of charge.

We began in Colombia in 2006. Our first

facility was a small rebuilt house, where

we first introduced the advantages of

the MIS system. There were only a few

commercial implant brands at that time

and MIS was new in Colombia. We knew

from the beginning that MIS offered an

excellent product and it became a priority

to teach dentists how to use it properly

in order to provide predictable treatment

for edentulous patients. We started with

lectures and hands-on treatments with

real patients, which was the most effective

method of training.

Today, there exists a strong synergy between

Esparza Enclosed and MIS Implants that

allows us to function as an independent

network linking scientific and clinical experts

in the field of oral implantology. We develop

research projects and all sorts of activities

to expand knowledge of implant dentistry

to achieve wellness for the patient. As an

independent academic organization, EE

aims for information exchange and contact

between its members, their training centers

and the dental industry.

Over 800 dentists visit our facilities annually

for training in implant dentistry including;

surgical and prosthodontic techniques,

orthodontics, esthetic dentistry, facial

esthetics, photography and more. We

currently run nine modern, well-equipped

Training Centers in Colombia, two in

Venezuela, one in Ecuador and another

in Mexico. We have an excellent team of

lecturers; most are university professors.

Our Institute is a reference center in Implant

Dentistry Education worldwide, training

dentists from Latin America, Poland, Canada,

Germany, Australia, Israel, Turkey and other

countries as well.

19 MNEWS 4th Quarter, 2013

Continuing to Grow for

the Future…

In countries where we have an established

distribution network, MIS is very well

positioned. Customers readily identify

and associate our products with excellent

service and scientific support. When we

first started these conditions did not exist.

Today, the amount of visitors to our facilities

and the invitations we receive to take part in

global, regional and local conferences, has

demonstrated to the Latin American market

that we are well-respected contenders. The

strength of the MIS brand; our experience,

expertise and dedication to quality really

does speak for itself. The plan for the next

five years is to continue growing in the

market, overcoming the challenges related to

unfair practices by competitors, developing

more diverse leadership strategies, opening

additional offices in Colombia, Ecuador,

and Venezuela, and of course, providing

even better service, education and support

to our customers.

Claudia Recalls a Proud

Personal Moment…

We are not only hard-working business

people; we are also parents, sometimes

striving to overcome the challenges of

balancing parenthood with a successful

career. However there are certain

moments that occur in life that joyfully

combine the two. The day we bought

our new office, we placed a large

dental implant replica in the front

garden of the building; a perfect

advertisement clearly visible from

the street. My eldest daughter told

me that in the morning when her

school bus passed by our office,

she proudly announced to all her

friends: “That big implant you see

there, that belongs to my family!”

The recognition I received from

my daughter was the best

of all, and we are truly very

proud of everything we have

accomplished.

20 MNEWS 3rd Quarter, 2013

Ms. Claudia P. Esparza

and Mr. Samy Akerman

21 MNEWS 4th Quarter, 2013

THE CANNES

EXPERIENCE!

ENERGY AND ENTHUSIASM FUELED THE 2nd MIS IMPLANTS GLOBAL CONFERENCE

THAT HOSTED ABOUT 2000 PARTICIPANTS FROM OVER 60 COUNTRIES DURING AN

EXCITING 3-DAY EVENT IN CANNES, FRANCE.

The conference theme, 360 Degrees

Implantology: From Science to Practice How to Make It Simple, revolved around

internationally recognized opinion leaders

22 MNEWS 4th Quarter, 2013

sharing practical experience, new research

and best business practices. “This was no

ordinary conference,” explains Mr. Idan

Kleifeld, MIS Implants CEO. “Throughout the

world, more doctors and patients than ever

before are using and benefiting from dental

implants. This has resulted in an urgent need

for doctors and implant professionals not

only to understand emerging technologies

and techniques in theory, but to gain real

practical knowledge of the latest implant

products, tools and procedures.”

Idan continues, “MIS is unique in the industry

by consistently providing a direct response

to the needs of dental implant professionals.

We bring to market top quality products and

procedures engineered for design simplicity

and efficiency; designed specifically to benefit

doctors, laboratories, dental practices, and

of course their patients.”

“First and foremost we are a business

about people,” says Mr. Doron Peretz,

MIS Implants Senior VP of Marketing and

Product Development. “The entire MIS team

is dedicated to the values built-in to every

part of our work process - quality, service and

innovation. We are proud to be world leaders

in a business that’s doing something good

for people and we are committed to doing

it right! Integrity, quality and hard work are

the keys to building something great, as our

recent MIS Global Conference proved, and it

was a great success for everyone involved. “

The MIS Global Conference made the most

of this world renowned venue for the Cannes

Film festival by celebrating in style, with a

red-carpet grand opening fit for the stars.

It featured the unveiling of the beautifully

designed new MIS video about the inspiration,

innovation and motivation that brought to

market some of the world’s best-selling

implants. In addition, the MIS dental implants

exhibit attracted a large crowd eager to

engage with staff to learn more about MIS

implant systems, prosthetics, accessories

and bone grafting materials.

The conference fulfilled a dual purpose;

not only boosting the market image of

MIS as one of the largest global implant

manufacturers, but also offering conference

goers a marvelous vacation experience

by organizing an unforgettable line-up of

top-class entertainments. The exciting ‘Tour

De MIS’ Charity Bike Ride kicked-off the

conference, with a 50km and 70km route

along the picturesque coastline of southern

France in support of ‘Operation Smile’, a

charity that specializes in the facial and dental

reconstruction for children worldwide. The

closing party was a stunning night out at the

famous Gotha club in Cannes.

24 MNEWS 4th Quarter, 2013

25 MNEWS 4th Quarter, 2013

Pa

ul A

.

26 MNEWS 4th Quarter, 2013

D

Schnitman, DDS, MS

A VISION

FOR THE

FUTURE

FROM A PIONEER IN

IMMEDIATE LOADING

IMPLANTS

MIS interview with

Paul A. Schnitman,

DDS, MSD

When did you start using dental implants?

In the late 60’s and early 70’s introductory courses on dental

implants were starting to become available. In 1971, as a young

dentist working in Connecticut, I became very excited by the

idea of replacing teeth with implants instead of just fitting

dentures. I saw an advertisement for a course being given at

The Brookdale Hospital Medical Center in Brooklyn New York

by Dr. A. Norman Cranin, a pioneer in implant dentistry. After

I completed the course, Dr. Cranin invited me to be the first

resident in the new Advanced Education Training Program for

Implant Surgery and Prosthodontics that he was establishing – a

collaboration between New York University and the Brookdale

Hospital Medical Center. I accepted with great enthusiasm, and

moved with my wife Phyllis to New York to become the first

university trained implantologist.

27 MNEWS 4th Quarter, 2013

It was there, my work with implants began

in earnest. Prior to the advent of root-form

endosseous implants, most implants were

either blade endosseous implants, in

that the shape of the metal piece placed

within the bone resembled a flat blade, or

subperiosteal implants, in which a framework

was constructed to lie upon the bone of the

jaws. We started with research on dogs,

testing blade implants with different loading

conditions, because in those years implants

were being placed in patients and restored

between 2-4 weeks with unpredictable results.

Many implants failed due to infection.

‘‘

improve their patient’s quality of life by virtue

of eliminating the need for a removable

prostheses, still, results were unpredictable.

Infection often set in early on, or after 4-5

years. Implant removal was difficult and

associated with significant bone destruction

with few options at that time for grafting and

reconstruction. This was a disappointment to

me; however I became even more determined

to help solve these problems. I sought a place

to do high level research and discussed

my hopes with Dr. Paul Goldhaber, Dean

of Harvard School of Dental Medicine. He

in turn hooked me up with Dr. Leonard

Shulman, who was the Principle Investigator

of two NIH grants involved in basic clinical

research to discover the effect

of surface design on implant

acceptability in baboons, and a

clinical trial in patients of the then

new “space-age” carbon implant.

Clinical research takes years,

and the dental implant industry

was forging ahead quicker than

our ability to answer research

questions. For me it became clear

that in order to make headway, we

would need one of the then new

NIH Consensus Development

Conferences that dealt with the

reality that the clinical application

was outstripping science. We

were awarded an NIH Consensus

Development Conference grant

which became known as the

Harvard Conference on the

Benefits and Risks of Dental

Implants, and the results of participants,

clinicians, researchers, and academicians

for the day were encouraging; 75% success

rate for 5 years. As a result of this experience,

I conducted a large NIH clinical trial; around

the same time the Branemark implant with

its 2 stage protocol was being introduced in

Toronto Canada in 1982, with 90% and higher

success rates. With results like these, it became

clear we could anticipate dental implant

surgery becoming a routine procedure.

Clinical research

takes years, and the dental

implant industry was forging

ahead quicker than our

ability to answer research

questions...’’

You are pioneer in immediate

loading implants. How did you

come up with that idea, when

everyone else was following

standard protocols?

I was passionate about dental implants being

a superior solution, and was expanding on

the idea of using different implant designs

and loading conditions ever since my Masters

Thesis in my implantology training program:

submerging, neck-exposed with no abutment,

neck-exposed with an abutment, and a

bridge immediately placed on the implant

at insertion (with the objective of identifying

the relationship to loading).

However, moving forward at that time was a

challenge. Academia held dental implants in

little esteem, and although it was a popular

idea with dentists because it could greatly

28 MNEWS 4th Quarter, 2013

So how did I start to immediate load 2-stage

implants? My practice in the mid eighties was

primarily full arch reconstructions for failing

dentitions, and my patients didn’t want to wear

dentures for an extended healing period. I

knew from my early loading research with

dogs and my clinical experience with blade

implants that any implant we put into bone

would stay stable for at least thee months.

Armed with that knowledge, I started to place

three implants to support a complete denture

while submerging the 5 required implants

adjacent to the immediately loaded implants.

I fully expected the immediately loaded

implants to fail, however that would only be

after the 5 submerged adjacent implants

had osseintegrated. Well, to my surprise

they didn’t fail and that was the beginning

of immediate loading of 2-staged implants.

It was during this period I began to understand

that in order to bring dental implant surgery

into the mainstream we needed to create a

standardized infrastructure for the training

and education of implant practitioners, and

not simply in order to refine basic research;

which is time-consuming, costly and complex.

Another factor was the patients themselves,

who were eager to become recipients of

implant technology, yet understandably,

didn’t want to wait for long-delayed clinical

results. With this vision for the future, I was

given the opportunity to chair the world’s

first ever university-based department of

Implant Dentistry; embodying a full spectrum

of formalized implant teaching, research

and patient care.

What do you see as being

the most important emerging

technology in implant dentistry

today?

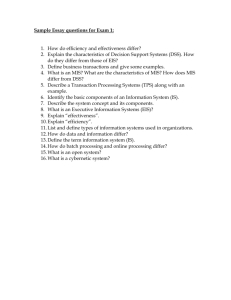

The first digital treatment planning and guided

surgery software was introduced in 2005. It

was revolutionary; less invasive, quicker, and

offered more precise placement. Precision

placement was the really groundbreaking

issue; elevating our success rates from freehand placement of 88% up to 100% success

rates with a virtual implant planning and

guided system – and zero failed implants.

I think that virtual implant planning and guided

implant surgery and restoration is the future,

and should be taught to everyone in the

field, not just veteran doctors. Within 5-10

years virtual planning and guided implant

surgery will be the norm. It’s a big plus for

the patient; however it will take a bit more

time to overcome some of the obstacles

to doctors; such as more prep time, new

training for support staff, interfacing between

lab and clinic, and the learning curve for new

techniques, equipment and software. Virtual

implant planning and guided implant surgery

is already easier and more economical

than it was just a few short years ago and

its evolving quickly. For the future I see this

technology being used to create 3D virtual

teeth and restorations (also to combine with

implants), eliminating the need for impressions

or waxing crowns, speeding up the procedure

and cutting down on patient visits.

MIS stands for Make It Simple.

How do you think dental

implantology can become

simpler?

In my mind, we must make it simple for the

doctor by developing standardized treatment

guidelines. In this way the doctor can more

readily identify the most efficient and cost

effective course of action for routine cases

time, less trauma, a decrease in hard and

soft tissue resorption, an increase in patient

acceptance and better aesthetic results. Yet

there are still no standard protocols in place for

these procedures. According to the traditional

protocols, 3-4 months of healing is required

for the consolidation of an extraction socket.

Add to this the 3-4 month osseointegration

period and prosthetic treatment times and

patients are often waiting up to 1 year for

tooth replacement.

SUCCESS RATES WITH FREE-HAND VS. GUIDED IMPLANT PLACEMENT

that will produce the best results. Then to

create similar guidelines suited to more

complex cases.

More advanced technology isn’t the only

answer. In order to keep success rates high and

achieve predictable results, we must provide

doctors with quality, standardized education

and training. Most implant companies focus

solely on product development. However

it’s equally as important to design more

streamlined procedures as well. The goal

would be to identify and categorize different

types of cases, also defining complexity

levels and extenuating conditions, and then

providing the recommended options for

effective and efficient procedures/treatments.

Another practical consideration in making it

simpler is to reduce delay times for implant

placement and loading. This is advantageous

for both patients and doctors. Today, early

or immediate loading following implant

placement and immediate implant placement

into the fresh extraction site with immediate

loading, has become more widely accepted.

It is popular due to reduced overall treatment

What are some of the challenges

affecting the future of implant

dentistry?

There’s not really that much new in the

industry aside from improved techniques and

materials to work with. We need to overcome

the problems inherent with the increased

usage of implants. With increased usage,

there will be a greater need for retreatment.

“Of paramount importance today is the

standardization of dental implant protocols.”

The most effective tool in tooth replacement

will be the refinement and maturation of the

education process – that’s really the key.

We need to create an industry-approved,

standardized curriculum and accepted

treatment protocols for oral implantology,

that takes into consideration the mouth as

an organ approach; not merely focusing on

an isolated implant procedure to fill a space,

often amongst other questionable teeth.

Please tell us about the MIS

Fellowship at HSDM. Why is it

important? What are the future

goals and plans of the MIS

Fellowship?

The Harvard School of Dental Medicine

(HSDM) now has an Implantology Fellowship

sponsored by MIS Implants Technologies Ltd.

The Fellowship provides for students who

have a strong commitment to academics,

with high quality training based on rigorous

science from researchers and clinicians that

will enable future implant practitioners to

adopt new techniques and procedures that

have already been validated. The Fellowship

is an important step in creating evidencebased research for further development of

streamlined protocols that will eventually

make implants more affordable to a wider

population. For the future, these clinical studies

will help us find ways to standardize dental

implant protocols and will be a critical step in

evaluating new products and technologies.

Candidates for the MIS Fellowship are

identified by their potential to provide future

leadership in implant dentistry.

The Harvard School of Dental Medicine

(HSDM) is grateful for the confidence that

MIS Implants Technologies has placed in

the School by funding the MIS Implantology

Fellowship. These funds have allowed the

inaugural recipient to complete specialty

training in both prosthodontics and

periodontics in May 2013, providing a platform

to contribute to the dental implant community

and to become one of its future leaders.

The fellowship has made possible for the

recipient to gain experience in making

research presentations at the annual sessions

of AO 2011 and 2012, 2013, AADR 2012,

AAID 2012, and ACP 2012. Further, the MIS

Fellow has become exposed to clinical trial

research techniques through participation

in the development of the MIS randomized

controlled clinical trial protocol and IRB.

We expect to launch that study in the third

quarter of 2013. The first MIS Fellow’s work

has raised the profile of the program, and

the HSDM community is well aware of MIS

as a socially responsible implant company

advancing implant dentistry at the highest

levels.

Now that the first Fellow has completed the

program, it is appropriate to discuss the future

of the Fellowship at HSDM. Since much has

been learned about implant training during

this inaugural fellowship, I believe that it

would benefit both the field and MIS, if the

Fellowship were to be continued for at least

another year. During this time we will refine

29 MNEWS 4th Quarter, 2013

We are excited about the potential of this

Fellowship and if it can be continued, we

have already identified a qualified advanced

graduate resident who perfectly embodies the

spirit and scholarship of the MIS Fellowship

with a commitment to a full time future in

academic implant dentistry. The student will

complete the advanced graduate program

in periodontology in 2014, and is a DDS with

a PhD in immunology. The student will then

be poised to become a leader in implant

dentistry with a research interest in the study

of peri-implantitis and implant clinical trials

research as well as academic curriculum

design. Becoming an MIS Fellow will allow

this candidate to assist in the development

of the pilot program to add in-depth implant

surgery to the HSDM Advanced Graduate

Prosthodontic Program.

‘‘

the goals and objectives of the program

in our efforts to determine the optimum

training methods for academic implant clinical

scholars and to provide a model for the

future. Currently, university-based advanced

education in Implant dentistry is provided in

several ways: Dedicated implant programs

providing both surgical and restorative

components, oral and maxillofacial and

periodontal programs providing the surgical

training, and prosthodontic programs providing

the restorative elements. During the first MIS

Fellowship we looked at adding a periodontal

program to a graduating prosthodontist. Now

we would like to explore a new concept the addition of full-blown implant surgery

into a prosthodontics program in our quest

to develop exceptional implant training in

less time.

‘‘ I think that virtual implant

planning and guided implant

surgery and restoration is the

future, and should be taught to

everyone in the field...

Paul A.

Schnitman,

DDS, MSD

Paul A. Schnitman, DDS, MSD, limits his private practice to Implant

Dentistry and is on the faculty at Harvard School of Dental Medicine.

He is a Diplomate of the American Board of Oral Implantology/Implant

Dentistry, Fellow of the Academy of Osseointegration and is a Fellow

and a past President of the American Academy of Implant Dentistry

and the American Board of Oral Implantology/Implant Dentistry. He is

30 MNEWS 4th Quarter, 2013

founder and former Chairman of the Department of Implant Dentistry at

the Harvard School of Dental Medicine. He has published widely, and

lectures nationally and internationally on the subject of dental implants.

© MIS Corporation. All Rights Reserved.

SCAN THIS PAGE

WITH LAYAR APP

NE

W

!

WHEN VIRTUAL

BECOMES REALITY

MAKE IT SIMPLE

Introducing the MGUIDE MORE, an advanced

virtual dental implant planning and guided

implantology system enabling real-time 2D and

3D visualization for perfect implant planning. Features

include user friendly software, the production of an

advanced open wire-frame template for accurate

guided implantation with predictable prosthetic

outcomes, special tool kit that eliminates the need

for guidance keys, and support from our worldwide

network of MCE NTE RS. Learn more at:

www.mis-implants.com

®

31 MNEWS 44thth Quarter,

Quarter, 2011

2013

Ms. Mindy Spielman

MIS Biomaterials

Product Manager

NEXT

GENERATION

REGENERATIVE

SOLUTIONS

MIS ANNOUNCES THE EXPANSION

OF ITS REGENERATIVE SOLUTIONS

PRODUCT LINE: 4BONE®

MIS has broadened our product portfolio to include

the expanded 4BONE line; a total biomaterials

solution package consisting of bovine, porcine

and synthetic based products.

Bone grafting is necessary in cases where there is

a lack of adequate maxillary or mandibular bone.

Sufficient bone is needed in three dimensions

to securely integrate with the implant. Improved

bone height—which is very difficult to achieve—is

particularly important to assure ample anchorage

of the implant’s root-like shape because it has to

support the mechanical stress of chewing, just

like a natural tooth.

Bone grafting typically involves small minimally

invasive interventions that can be managed quite

easily in a dental clinic. While bone grafting in the

past may have involved harvesting and using large

quantities of the patient’s own bone (autogenous

grafts), today however, one of the popular options

available are xenografts, processed bone harvested

from animals (i.e., cows). These grafts are generally

comprised only of the mineral content of natural

bone, and have been sterilized with all organic

material removed.

Using bovine bone as a graft material has become

commonplace in most oral surgical offices today

and has been a tried and proven technique for

many years. A simplified explanation for the success

of this form of grafting is that a bovine bone graft

is placed to act as a “biological placeholder.”

Initially, it mechanically prevents the collapse of

the surrounding tissues, whether that is bone or

soft tissue. Then, through a process called “guided

bone regeneration,” the human body is fooled

biochemically to recognize the graft as natural

bone and over time resorbs and replaces it with

the patient’s own native bone.

Flexibility is a key feature of the new 4BONE

product range. 4BONE products can be mixed

together in various configurations to achieve

more flexible treatment solutions, i.e. resorption

time and types of bone matrix required. Products

are packed in varying weights and volumes, for

simple and easy delivery directly to the surgical site.

33 MNEWS 4th Quarter, 2013

MIS regenerative products also mix

readily with other biomaterial brands.

MIS best serves our customers by

providing a wide range of quality bone

grafting materials, membranes and

accessories to answer almost any

clinical scenario. Quality equipment and

design control processes assure high

standards of sterilization and safety for

all 4BONE products; making it safer

and making it simple.

The new 4BONE series now includes

the following products:

4BONE® XBM - Bovine

Bone Matrix

XBM is an anorganic bovine bone

mineral matrix for use in bone

regeneration procedures, and

recommended for use as a bone

void filler or augmentation material in

periodontal defects and dental implant

procedures.

It is produced by removal of all organic

components from bovine bone, leaving

the natural mineral component for

use as an osteoconductive material

for bone regeneration. Due to its

natural structure, 4BONE XBM is

physically and chemically comparable

to the mineralized matrix of human

bone. The trabecular architecture

with interconnecting macro and

micro pores, allows for the

optimal ingrowth of

new vascularity and

bone at the graft

site and maximizes

the potential for

angiogenesis.

4BONE® BCH - Synthetic

Bone Substitute

BCH is a fully synthetic bioactive bone

substitute composed of chemical

synthesis of 60% HA and 40% ß-TCP.

It is recommended for use as a bone

augmentation material in dental implant

procedures and periodontal defects.

With its interconnected micro and

macro porosity and osteoconductive

properties, BCH attracts osteogenic

cells and promotes the diffusion of

biological fluids, providing a guaranteed

homogenous distribution and diffusion

34 MNEWS 4th Quarter, 2013

of the two phases. BCH has optimized

morphology and resorption properties

to provide flexibility and a predictable

healing process for a wide range of

bone regeneration procedures.

BONDBONE® - Bonding

Graft Material

BONDBONE® is an innovative synthetic

bone grafting material composed of

biphasic calcium sulfate. Due to it novel

engineering process, BONDBONE

has excellent handling properties. The

initial pliable paste is fast setting and is

not affected by the presence of blood

and saliva.

This resorbable, osteoconductive bone

grafting material takes the best qualities

of hemihydrate and dehydrate calcium

sulfate and combines them into one

unique product. When combined with

other augmentation products, it acts as

a binder to improve graft stability and to

increase volume and effectiveness of the

bone graft. BONDBONE can be used

by itself as a highly effective material

for socket preservation procedures

and the augmentation of small defects.

4BONE® RCB Resorbable Conforming

Barrier Membrane

RCB is engineered from highly

purified Type I bovine collagen. It

is a fully resorbable and adaptable

cell occlusive barrier used in guided

tissue regeneration and guided bone

regeneration procedures in the areas

of dental implants, bone defects and

ridge augmentation.

Upon hydration, the barrier membrane

easily adapts and adheres to all surgical

sites and promotes healing of bone and

soft tissue. RCB can be easily trimmed

and does not deform or adhere to itself

or instruments when hydrated. The

optimal mechanical properties and

high tensile strength of RCB allows

for easy placement and adaptability in

ridge augmentation procedures, due

to its ability to naturally conform

to the site where it is placed.

4BONE® RSB Resorbable Collagen

Barrier Membrane

RSB is a bioresorbable, cell occlusive

membrane engineered from highly

purified bovine collagen. It is indicated

for use as a barrier membrane in guided

tissue regeneration and guided bone

regeneration procedures in the area

of dental implants, bone defects and

ridge augmentations.

Due to its optimal initial rigidity and

defined stability, the RSB Membrane

is the product of choice to prevent

soft tissue ingrowth during healing in

defects that lack bony wall support.

Its semi-permeable properties permit

the exchange of essential nutrients for

healing, while the porosity qualities

effectively hinder epithelial down growth;

preventing gingiva connective tissue cell

migration into the treated site. Optimal

resorption time allows for sustained

function during the healing process.

4BONE® PLUG and

TAPE- Wound Dressings

4BONE PLUG and TAPE products are

used following oral surgical procedures

to control bleeding, stabilize blood

clots and aid in wound healing. They

are engineered from highly purified

cross-linked type I bovine collagen with

an optimal structure and thickness to

allow the absorption of both fluid and

blood at the defect site.

These sterile dental wound dressings

are engineered from bovine Type I

collagen. They protect the oral wound

bed and controlling bleeding due the

hemostatic properties of collagen fibers.

Both the PLUG and TAPE are fully

resorbed within 10-14 days.

TAPE

PLUG

BCH

RCB

RSB

XBM

BOND®

BONE

RCM

®

COMPETITIONS

R&D

WINNERS

OF THE MIS

CLINICAL CASE

COMPETITION

Starting a new tradition, MIS has established a Clinical Case Competition

to acknowledge outstanding young clinicians. The aim of the competition

is to promote clinical excellence in dental implantology, and to open up the

stage to young clinicians. Four recipients received awards on the topic of

immediate placement and loading in the esthetic zone. The winning cases

were presented at the 2nd MIS Global Meeting in Cannes, France.

*To see complete clinical cases visit our site: www.mis-implants.com

38 MNEWS 4th Quarter, 2013

First Prize:

Dr. Paolo Cardelli

“Immediate post-extraction implant with

immediate provisional and simultaneous

buccal ridge augmentation with

composite graft.”

Second Prize:

Dr. Joile Alvarez

Cantoni

“The combined use of MIS dental

implants and BONDBONE, for

immediate procedures in the

esthetic zone.”

Third Prize

shared:

Dr. Emilio Mateo

Dr. James R. Collins

“Minimally invasive surgery for postextraction immediate implant C1 MIS

with 4BONE graft and immediate

loading in the aesthetic zone.”

“Implant placement in the esthetic zone.

Surgical and prosthetic management.

Clinical case report.”

SCAN THIS LOGO WITH LAYAR APP

IT’S A

GREAT

APP!

INTRODUCING THE

MIS PRESENTATION

APPLICATION

The MIS TABCASE gives you the ability

to show great looking, ready-made

interactive presentations for offline

viewing on IPads. It’s the new musthave tool for sales, demos, training and

general information pertaining to implant dentistry and support

products and technologies. We offer an extensive collection of

high quality presentations on a range of subjects.

Check out our collection regularly for new presentations.

42 MNEWS 4th Quarter, 2013

APPLICATION

AAP

28 September,

2013

Philadelphia, USA

Annual

Congregation

of Association

of Hungarian

Dentists

6 September,

2013

Hungary

MIS Club

Exclusive Club

Event for MIS

Users

SEPTEMBER

3 October, 2013

Hungary, Budapest

OCTOBER

AAOMS

Annual

Meeting

AAID

Southern/

Northeast

District

Meeting

23-26 October,

2013 Phoenix

JW Marriott,

USA

7-10 October,

2013

Orlando, FL, USA

UPCOMING

EVENTS

DENTAL

WORLD 2013

International

Dental

Exhibition and

Conference

ADA

EAO

46 MNEWS 4th Quarter, 2013

28 October, 2013

Hotel Sheraton

Buenos Aires,

Argentina

17 October, 2013

Budapest, Hungary

2013

All rights reserved. No part of this publication may be reproduced,

transcribed, stored in an electronic retrieval system, translated into

any language or computer language, or be transmitted in any

form whatsoever, without the prior written consent of the publisher.

Congreso de

la Asociacion

Odontologica

Argentina

17-19 October,

2013

Dublin, Irland

31 October,

2013

New Orleans,

LA, USA

Taipei Academy

of Oral

Implantology

ADF Annual

International

Conference and

Trade Exhibition

2 November, 2013

Taipei, Taiwan

27-30 November, 2013

Paris, France

The fifth

Prosthodontics

Professional

Committee

SECIB Sociedad

de Cirugía Bucal

28-30 November, 2013

Madrid, Spain

12-14 November, 2013

Wuhan, China

GNYDM

DIA Melbourne

Campus

(2 days/16 CEU)

Basic Implantology

29 November, 2013

Javits Center, New

York City, USA

23-24 November, 2013

DIA Melbourne Campus

DECEMBER

TAO

NOVEMBER

14-16

December,

2013 Taipei,

Taiwan

© MIS Corporation. All rights reserved.

MAKE IT

SI M PLE

Dublin, Ireland.

SCAN THIS PAGE

WITH LAYAR APP

tive

r innova

about ou at:

re

o

m

s

rn

To lea , please visit u

products

10

Booth #G

THE FUTURE IS NOW! MAKE IT SIMPLE

We are pleased to invite you to join us in “Preparing for the Future of Implant Dentistry”,

the theme for the 22nd Annual Scientific Congress of the EAO, to be held in Dublin,

Ireland, October, 17th to 19th 2013. Learn about MIS Implants - visit our site: mis-implants.com.