as a PDF

advertisement

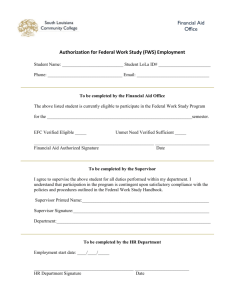

Environmental Technology, Vol. 28. pp 621-628 © Selper Ltd., 2007 PERFORMANCE AND COST COMPARISON OF A FWS AND A VSF CONSTRUCTED WETLAND SYSTEM V. A. TSIHRINTZIS1*, C. S. AKRATOS1, G. D. GIKAS1, D. KARAMOUZIS2 AND A. N. ANGELAKIS3 1 Laboratory of Ecological Engineering and Technology, Department of Environmental Engineering, Democritus University of Thrace, 67100 Xanthi, Greece 2 Hydraulics, Soil Science and Agricultural Engineering Division, Department of Agriculture, Aristotle University of Thessaloniki, 54124 Thessaloniki, Greece 3 Institute of Iraklio, National Foundation for Agricultural Research, P.O. Box 2229, 71307 Iraklio, Greece (Received 1 February 2006; Accepted 10 January 2007) ABSTRACT Two constructed wetland systems, treating domestic wastewater, are compared in terms of performance and costs. One is a free water surface (FWS) wetland system located in Pompia, Crete, south Greece, and the other one is a vertical subsurface flow (VSF) wetland system located in Gomati, Chalkidiki, north Greece. The FWS system is designed for 1200 p.e. Its construction cost was 305,000, and the capital, operation and maintenance cost was 22.07 p.e.-1 yr-1 or 0.50 m-3 of influent. The VSF system is designed for 1000 p.e. Its construction cost was 410,850, and the capital, operation and maintenance cost was 36.81 p.e.-1 yr-1 or 0.56 m-3 of influent. Both systems achieved high removal rates for BOD5, COD, TSS, TKN, phosphorus, TC, and FC, which makes them ideal for small communities in the Mediterranean region. Keywords: Free-water surface constructed wetland, vertical subsurface flow constructed wetland, treatment performance, construction cost; operation cost are now installed for single family use (e.g., [19]). INTRODUCTION The aim of this paper is to provide a perspective for Constructed wetland (CW) wastewater treatment applying constructed wetland technology in the systems are considered more reliable compared to Mediterranean conventional systems [1], and are ideal technologies for small Descriptions, communities, due to their low construction, operation and constituent maintenance costs, easy adaptation to the environment and maintenance (O&M) costs of two constructed wetland limited generation of by-products [2,3]. systems (a FWS and a VSF) are presented. Both systems treat One question however, is which is the optimum CW regions design removal and specifically considerations, performance, in Greece. construction and operation cost, and domestic wastewater and were designed for comparable type (i.e., free-water surface (FWS), horizontal subsurface flow treatment capacities. (HSF) or vertical subsurface flow (VSF) system) to use in a specific region, in terms of performance, costs, area requirements, and other factors. Most studies in the literature METHODS AND MATERIALS emphasize specific systems in terms of general performance System Description [4-9]. Other studies examine the effect of various design parameters [10-13]. Comparisons of various CW types in the same region are limited (e.g., [14,15]). Construction and other Two constructed wetland systems treating domestic cost data for CW systems are also limited (e.g., [16]). The wastewater are compared in terms of costs and performance. necessity of pretreatment is an issue for discussion, since One is a FWS wetland system located in Pompia, Crete, South modified VSF designs in France operate successfully without Greece, and the other is a VSF wetland system located in pretreatment [17, 18]. Finally, small-scale on-site CW systems Gomati, Chalkidiki, Macedonia, North Greece. 621 maximum hourly flow rate 27.7 m3 h-1; influent biochemical FWS system The main components of the FWS system are [20]: (a) a oxygen demand (BOD5) 400 mg l-1; septic tank effluent BOD5 septic tank (up-flow reactor simulation) equipped with three 250 mg l-1; wetland effluent BOD5 10 mg l-1 and (COD) <50 mg screen vault filters [3]; (b) a FWS constructed wetland l-1; retention time 5-14 d (depending on the season of the consisting of two basins in series, with surface areas of 4300 year); sewage average temperature in the winter 10 °C and in m2 and 1200 m2 (the inflow is uniformly distributed across at the summer 22 °C. the inlet of each basin using manifolds); (c) two chambers, one in each basin, for regulating the water level; (d) small pumps VSF system and a pipeline for the recirculation of the effluent back to the The main components of the facility are: (a) inflow inlet of the first basin; (e) a compost filter for odor control in structure; (b) a rotating disk screen with 1 mm openings; (c) a the septic tank. Vegetation selection included two species of reeds closed twin settling tank (48 m3 each chamber; dimensions 4m (Phragmites australis and Arundo donax). The facility was x 6m x 2.5 m); (d) a closed twin sludge digestion-stabilization constructed in the early months of 1999. The vegetation was tank (48 m3 each chamber; dimensions 4m x 6m x 2.5 m); (e) planted late in the winter of the same year, and due to the an open siphon tank (3.2 m3; dimensions 1.0 m x 4.2 m x 0.8 favorable climatic conditions prevailing in the area, it m) for intermittent wastewater feeding (Figure 1); (i) a stage I established well very rapidly. By the end of the year, the VSF circular basin (4 cells, 640 m2, sand and gravel fill, 1 m vegetation was very dense and more than two meters in deep); (g) a stage II VSF circular basin (4 cells, 360 m2, sand height. and gravel fill, 1 m deep); (h) a stage III rectangular HSF cell The basic parameters used in the design of the FWS (800 m2, sand and gravel fill, 0.5 m deep); (f) a VSF circular facility are [20]: population served 1200 p.e.; mean daily flow basin (4 cells, 240 m2) which receives digested-stabilized 3 rate 144 m -1 3 d ; maximum daily flow rate 216 m Figure 1. -1 d ; sludge for drying and storage. All wetland basins are planted View of the siphon tank of the VSF system. 622 with Phragmites australis. The HSF cell was not planted at the settling tank outflow, siphon, stage I VSF outflow and stage II time of the study and was out of the wastewater stream. The VSF outflow over a monitoring period from July 2003 to VSF system was planted in May 2003 and was immediately August 2004. The samples were analyzed in the laboratory put to operation. The plants were dense and nearly fully- following APHA standard methods for BOD5, COD, TSS, grown by October 2003. Total Kjeldhal Nitrogen (TKN), Total Phosphorus (TP) or PO4, Total Coliforms (TC) and Faecal Colifoms (FC). Calculations The route of the wastewater through the system is the following: from the inflow structure to the rotating disk of screen and to the settling tanks. The sludge is collected at the concentrations were performed in a spreadsheet. statistical parameters of measured constituent bottom of the settling tank (estimated volume 4.8 m3 week-1), it is then pumped to the sludge digestion-stabilization tanks, Cost Evaluation Method and then to the VSF sludge basins. The leachate collected at the bottom of the VSF sludge basins is pumped back to the The actual construction cost of the two systems was siphon, and together with the wastewater from the settling used. Since the FWS system was constructed in 1999 and the basins feed the stage I VSF basin (2 cells operate at a time). VSF in 2003, for comparison the cost of the FWS was Then, the wastewater is led to the stage II VSF basins (2 cells expressed in 2003 prices using a reported inflation rate of operate at a time). In the future, the flow will continue to the approximately 3.1%. An economical life of 30 years and a stage III HSF basin (not in operation now). The effluent of the capital discount factor of 6% were assumed to calculate net- basin discharges into a nearby stream, approximately 5 km present-value cost [21]. Operation and maintenance costs from the coast. were obtained for the operation time periods from the records of the local authorities operating the two facilities, and were The main design parameters for this system are summarized as follows: the design population is 1000 p.e. The expressed in 2003 prices for the FWS system. design mean daily flow of the system is 180 m3 d-1. The maximum hourly flow is 28.5 m3 h-1. The design hydraulic RESULTS loading rate is about 36 m yr-1, and the organic loading rate 196 kg ha-1 d-1. Design influent and effluent concentrations are System Performance as follows: for BOD, influent 330 mg l-1, settling tank effluent 196 mg l-1, VSF effluent 12 mg l-1, HSF effluent < 10 mg l-1. For FWS system total suspended solids(TSS), influent 380 mg l-1, settling tank The results during the 3-year period of the FWS facility effluent 80 mg l-1, VSF effluent 12 mg l-1, HSF effluent < 10 mg monitoring could be summarized as follows: mean BOD5, l-1. COD and TSS removals about 95%, mean TKN and TP removals about 53%, and TC and FC removals >97% (without System Monitoring, Sample Analysis and Statistics any disinfection). Removal efficiencies of BOD5, COD, TSS, TKN and TP in the final effluent for the monitoring period are Grab samples were collected regularly at various points presented in Table 1. Very high removal rates of BOD5, COD along the FWS system (i.e., inlet, settling tank outflow and and TSS (94.4%, 96.1%, and 95.6%, respectively) have been system outflow) over a 3-year monitoring period from August observed in the septic tank. On the other hand, low removal 1999 to August 2003, and along the VSF system (i.e., inlet, rates of TKN and TP of 52.5% and 53.1%, respectively, have Table 1. Measured concentrations of BOD (mg l-1), COD (mg l-1), TSS (mg l-1), TKN (mg l-1), and TP (mg l-1) in the influent (IN), the septic tank effluent (SE) and the final effluent (FE), and overall efficiency (TE, %) for the FWS system in Pompia, Crete, Greece. Parameter BOD IN SE FE COD TE mg l-1 IN SE FE mg l-1 % TKN TSS TE IN SE FE mg l-1 % TE IN SE FE mg l-1 % TP TE IN SE FE mg l-1 % TE % Average 165 39 7.7 94.4 455 100 18 96.1 191 36 5.6 95.5 38 25 18 52.5 13 9.1 6.2 53.1 Std. Error 31 4.0 1.3 1.0 31 9.8 2.7 0.5 40 5.4 0.8 0.9 3.4 1.7 1.7 4.8 1.5 1.3 1.1 4.7 Min 52 11 2.0 86.5 280 44 2.0 92.7 38 4.0 1.0 86.8 17 8.0 4.0 23.1 4.8 2.3 1.6 10.6 Max 540 60 16 99.1 798 180 40 99.6 720 90 12 99.3 62 36 27 83.1 24 22 21 78.5 # of Data 14 14 15 14 17 18 18 17 18 18 17 18 18 17 18 18 17 17 623 17 17 been obtained in the tank. TN and TP removed in the septic hydraulic path of the system. It is obvious that to improve tank were probably in organic form as particulate organic nitrogen and phosphorus removals the last stage of the matter. Lower removal rates of various constituents in similar system should also be planted and be put soon in operation. septic tanks have been reported [3]. System Costs VSF system The monitoring results of the VSF system during the 13- FWS system month period of operation could be summarized as follows: System cost calculations are presented in Table 3. The BOD5 removals >92%, TKN removals >89%, and TC removal actual capital cost for the FWS system was 305,000 (prices of >99% (without any disinfection). Removal efficiencies of 1999, including 18% VAT). To compare this cost with that of BOD5, COD, TSS, TKN and TP in the final effluent for the the VSF system, it was expressed as 344,615 in 2003 prices monitoring period are shown in Table 2. Removals are (287.18 p.e.-1) using the 3.1 % inflation rate. This cost also satisfactory, considering that the facility was still new and the includes 115,000 for access road and administration room plant root system was probably not fully developed yet. construction and other works. Some of this work was not Relatively, high removal rates of BOD5, COD and TSS have actually necessary, such as extra roads outside of the facility. been measured in the settling tanks. On the other hand, lower In addition, the soil used for planting in the treatment cells removal rates of TKN (77%) were observed, while TP removal was transported from a distance of more than 10 km with a showed fluctuation and some times increased along the relatively high cost. This work was also unnecessary. The net- Table 2. Measured concentrations of BOD (mg l-1), COD (mg l-1), TSS (mg l-1), TKN (mg l-1) and TP(mg l-1) in the influent (IN), the settling tank effluent (STE), the VSF effluent (VSF) and overall efficiency (TE, %) for the VSF system in Gomati, Chalkidiki, Greece. Parameter BOD IN COD STE VSF TE mg l-1 % IN TSS STE VSF mg l-1 TE IN TKN STE VSF mg l-1 % TE IN TP STE VSF TE mg l-1 % IN STE VSF TE mg l-1 % % Average 485 193 39 92 626 243 62 89 1077 208 9 95 77 51 14 77 17.5 8.2 5.6 62 Std. Error 246 111 29 6 260 119 31 6 1784 474 13 8 47 50 6 20 9.0 3.9 3.1 22 Min 62 10 4 78 238 96 0 81 26 23 0 75 0 8 0 31 7.5 4.3 2.4 24 Max 819 355 92 100 1171 465 106 100 7060 2158 47 100 187 251 27 100 29.3 14.9 11.9 89 # of Data 20 19 20 20 20 19 20 20 20 19 20 20 20 19 20 Table 3. Capital and operating costs () for the two facilities. Cost () Cost category FWS System VSF System Capital, including VAT (construction cost) 344,615 410,850 Construction cost per p.e. 287.18 410.85 Net-present-value cost 25,036 29,848 Annual average O&M cost 1,445 6,960 O&M cost per p.e. per year 1.20 6.96 O&M cost per m per year 0.03 0.11 Total annual cost (capital and O & M) 26,481 36,808 Total annual cost per p.e. 22.07 36.81 0.50 0.56 3 3 Total annual cost per m of influent 624 20 8 8 8 8 present-value cost was estimated at 25,036 yr-1 using a 6% p.e.-1yr-1 or 0.56 m-3 of influent. discount factor. The total mean operation and maintenance Design, Construction and Operation Problems (O&M) cost of the FWS system in the first three years of operation was estimated at 1,445 yr-1 (i.e., 1045 for energy used, 300 for works, and 100, for miscellaneous expenses) No major problems were observed in the FWS or 1.20 p.e.-1 yr-1 or 0.03 m-3 of influent. Net-present-value constructed wetland. It seems that this CW has been cost and O&M cost are added to a total annual cost of 26,481, designed, constructed and is operated very successfully. The and the mean figures become 22.07 p.e.-1 yr-1 or 0.50 m-3 of VSF constructed wetland achieves a high removal efficiency influent. for all pollutants. Nevertheless, it is believed that its performance could be even better if some design, construction and operation problems were resolved. These can be VSF system summarized as follows. The total construction cost of the VSF system was 410,850 (prices of 2003, including 18% VAT) or 410.85 p.e.-1 Design problems This construction cost also included costs for access road (250 A major design problem is the sizing of the siphon that m paved road), construction of 550 m sewer line to bring feeds the first stage of the VSF cells (Fig. 1). The dimensions of wastewater to the facility and 400 m sewer line for effluent this siphon are 10x4.2x0.8m or 3.2m3 of flooding volume. The disposal to the final receiver, fencing, landscaping and other siphon floods two cells at a time, i.e., 320 m2, therefore, the works. These extra works are estimated at about 100,000. average flooding depth is 1.0 cm. If one considers surface The net-present-value cost was estimated at 29,848 yr-1. The irregularities of the planted cells, it is obvious that this depth operation cost for the VSF system (for the first 10 months of is small. Usually, 4 to 5 cm of flooding depth are operation) comprises electricity (lighting and operation of 9 recommended. This problem was obvious in this facility. The pumps, estimated at 67.50 month-1 on the average), salaries flooding was limited to about a 1 m wide area around the for the operator and maintenance works (500 month-1 on the perforated feeding pipes (Fig. 2), something seen by denser average) and miscellaneous other expenses (12.50 month-1). plant growth in this area. Therefore, a major part of the Therefore, the total operation cost is approximately 580 available facility area was not used, reducing active treatment month-1 or 6,960 yr-1 or 6.96 p.e.-1 yr-1 or 0.11 m-3 area and performance. To fix this problem, it is recommended of influent. Net-present-value cost and O&M cost are added to that the siphon is replaced to one of a larger size that would a total cost of 36,808 and the mean figures become 36.81 provide at least 4 cm of flooding. Figure 2. View of the stage I distribution pipe. 625 Constructions problems It is recommended that these problems are addressed to A construction problem was the proper placing of the improve the system treatment performance. porous media and the installation of filtering material. Some porous media was washed out from the drainage pipe at the DISCUSSION AND CONCLUSIONS bottom of the wetland cells. Obviously, this was a result of not placing proper filtering material. As a result, seepage holes In general, selection of the appropriate constructed developed at areas of the cells from where wastewater could wetland system depends on wastewater characteristics, seep out untreated. Another construction problem was in the experience gained, local conditions and site constraints. FWS last stage (HSF), which was not perfectly level in the lateral to systems are less expensive to construct, to operate and to the flow direction, resulting in preferential flow (and plant maintain, are less sensitive and susceptible to problems, and growth) on one side (Fig. 3). Again, this resulted in reduction have greater potential for wildlife support. VSF systems in total active treatment area and perfomance. generally require less land area, are less susceptible to freezing, mosquitoes and odor problems, and do not have wastewater exposed at the surface, thus providing minimal Operation and maintenance problems Operation and maintenance problems were also human contact and health risks. These systems are considered observed in some of our visits. For example, plants were more susceptible to clogging of the media. However, grown (and not removed) inside the outlet overflow pipe of neither odor nor clogging problem in either system has the last HSF stage, obstructing outflow and resulting in been observed so far. It is noted that a possible problem flooding of the system. of mosquitoes in the FWS project was faced effectively by Figure 3. View of the HSF constructed wetland cell. 626 and storage) or 2.04 m2 p.e.-1 Thus, as expected, the VSF planting from the start Gambusia spp. fish. In terms of performance, the organic loading rates were system provides comparable treatment at significantly slightly higher in the VSF than in the FWS system. less area (less than half), for slightly higher average Furthermore, ambient temperatures in the VSF system, design flow rate (180 m3 d-1 vs. 144 m3 d-1), and at lower o located in Northern Greece, are 5 to 10 C lower. Nevertheless, operational temperatures (north vs. south Greece). the high efficiency of both systems has been observed. The d. When comparing the construction costs of the two cost analysis, incorporating both capital and operation and systems, it seems that the VSF is slightly more maintenance costs, also suggested a low cost for both systems. expensive, probably due to the fact that this system The FWS system was less expensive to construct and to contains more concrete and several pumps. Generally, operate. However, the VSF system required considerably less the FWS system construction is much simpler. In terms land area (in this economic analysis the price of land was not of the capital and operation cost, it also seems that the considered). In terms of construction and O&M problems, the FWS system is less expensive. Both systems are VSF system, which is more complex in design, construction considered less expensive, both in construction and and operation, showed most problems, which, however, could operation, when compared to equivalent conventional have been predicted and avoided from the beginning. Finally, treatment systems operating in the same areas. the FWS system may freeze for a few days in the winter, if e. When comparing design, construction operation and installed in areas where the temperature drops below 0oC maintenance problems it seems that, the VSF was more (e.g., North Greece). susceptible to problems since it is a more complex More specifically, the following can be drawn from the system. For both systems, careful design and comparison of the FWS and VSF systems: construction, and proper maintenance are very a. important. b. Constructed wetlands are considered appropriate wastewater treatment systems for the Mediterranean In conclusion, the treatment efficiencies of the two environment, generating excellent quality of effluent at systems are comparable (except for TKN and TP where the the secondary treatment level. In this comparative VSF system had higher removal efficiencies), costs seem to be study, BOD5, COD and TSS reductions of about 95% less for the FWS system, and land requirements are quite were observed for the FWS CW. BOD5 and TSS lower for the VSF system. Thus, one can select either system reductions were similar for the VSF system, while COD in terms of treatment efficiency. When land is available, the reduction was about 89% for this system. In addition, FWS system would be preferable because of its simplicity, less for the FWS system reductions of TKN and TP of about expensive construction, and more reliable and problem-free 53% were measured, and removal rates of TC and FC of operation. If land availability is a problem or land value is 98.7% and 97.1%, respectively. For the VSF system, TKN high, then the VSF system would be more preferable. A removal was 77% on average, while mean phosphorus careful design and construction, and proper maintenance are removal efficiency was 62%. necessary in any case to avoid operational problems. Reasons for the lower efficiency of the VSF system in COD removal may be that it was new at the time of the ACKNOWLEDGEMENTS study and the plant roots were probably not fully c. developed. Furthermore, the HSF basin of the system We thank G. Dialynas, N. Kefalakis and K. Tsagarakis was not in operation during the study. Nevertheless, the for providing information on the study. Sample collection and two systems seem to be very promising in producing a analyses for the VSF constructed wetland system were high effluent quality. performed by A. Paltsoglou, K. Vragalas and J.N.E. The total wetland area (after pre-treatment) of the FWS Papaspyros. The evaluation of the VSF system was co-funded system is 5500 m2 (4.58 m2 p.e.-1), while that of the VSF by the European Social Fund & National Resources – EPEAEK system is 2040 m 2 (including 240 m2 for sludge drying II – PYTHAGORAS II. REFERENCES 1. Ansola G., González J.M., Cortijo R. and de Luis E., Experimental and full-scale pilot plant constructed wetlands for municipal wastewaters treatment. Ecol. Eng., 21, 43-52 (2003). 2. 3. Kadlec R. and Knight R., Treatment Wetlands, CRC Press, USA, Boca Raton, Fl., (1996). Crites R. and Tchobanoglous G., Small and Decentralized Wastewater Management Systems, WCB and McGraw-Hill. New York. USA (1998). 4. Andersson J.L., Kallner Bastviken S. and Tonderski K.S., Free water surface wetlands for wastewater treatment in Sweden – nitrogen and phosphorus removal. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, 627 IWA, Avignon, France, September 26-30, Vol. 1, pp. 39-47 (2004). 5. Koottatep T., Surinkul N., Polprasert C., Kamal A.S. and Srauss M., Treatment of septage in constructed wetlands in tropical climate – Lessons learnt after seven years of operation. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, IWA, Avignon, France, September 26-30, Vol. 1, pp. 249-257 (2004). 6. Cooper D., Griffin P. and Cooper P., Factors affecting the longevity of sub-surface horizontal flow systems operating as tertiary treatment for sewage effluent. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, IWA, Avignon, France, September 26-30, Vol. 1, pp. 259-267 (2004). 7. Solano M.L., Soriano P. and Ciria M.P., Constructed wetlands as a sustainable solution for wastewater treatment in small villages. Biosystems Eng., 87, 109-118 (2004). 8. Cameron K., Madramootoo C., Crolla A. and Kinsley C., Pollutant removal from municipal sewage lagoon effluents with a free-surface wetland. Water Res., 37, 2803-2812 (2003). 9. Ran N., Agami M. and Oron G., A pilot study of constructed wetlands using duckweed (Lemna gibba L.) for treatment of domestic primary effluent in Israel. Water Res., 38, 2241-2248 (2004). 10. He Q. and Mankin K., Performance variations of COD and nitrogen removal by vegetated submerged bed wetlands. J. Am. Water Resour. Assoc., 38, 1679-1689 (2002). 11. Mayo A. W. and Mutamba J., Effect of HRT on nitrogen removal in a coupled HRP and unplanted subsurface flow gravel bed constructed wetland. Phys. Chem. Earth, 29, 1253-1257 (2004). 12. Korkusuz E. A., Beklioglu M. and Demirer G.N., Comparison of gravel and slag based vertical flow reed bed performance in Turkey. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, IWA, Avignon, France, September 26-30, Vol. 1, pp. 173-181 (2004). 13. Akratos C. and Tsihrintzis V.A., Pilot-scale constructed wetlands for wastewater treatment studies. In: Proc. of the International Conference on Protection and Restoration of the Environment VII, Technical University of Athens, Greece and Sterens Institute of Technology, USA. June 28-July 1, 2004, Mykonos, Greece, CD-Rom Section IV (Ecological Engineering Applications), #1 (2004). 14. Rousseau D.P.L., Vanrolleghem P.A. and De Pauw N., Constructed wetlands in Flanders: a performance analysis. Ecol. Eng., 23, 151-163 (2004). 15. Luederitz V., Eckert E., Lange-Weber M., Lange A. and Gersberg R.M., Nutrient removal efficiency and resource economics of vertical and horizontal flow constructed wetlands. Ecol. Eng., 18, 157-171 (2001). 16. Söderqvist T., Constructed wetlands as nitrogen sinks in southern Sweden: An empirical analysis of cost determinants. Ecol. Eng., 19, 161-173 (2002). 17. Molle P., Liénard A., Boutin C., Merlin G. and Iwema A., How to treat raw sewage with constructed wetlands: An overview of the French systems. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, IWA, Avignon, France, September 26-30, Vol. 1, pp. 11-19 (2004). 18. Paing J. and Voisin J., Vertical flow constructed wetlands for municipal wastewater and septage treatment in French rural area. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, IWA, Avignon, France, September 26-30, Vol. 1, pp. 315-323 (2004). 19. Brix H., Danish guidelines for small-scale constructed wetland systems for onsite treatment of domestic sewage. In: Proc. of the 9th International Conference on Wetland Systems for Water Pollution Control, IWA, Avignon, France, September 26-30, Vol. 1, pp. 1-9 (2004). 20. Dialynas G.E., Kefalakis N., Dialynas M.G. and Angelakis A.N., Performance of the first free-water surface constructed wetland system in Crete, Greece. Water Sci. Technol., 46, 355-360 (2002). 21. Tsagarakis K.P., Mara D.D. and Angelakis A.N., Application of cost criteria for selection of municipal wastewater treatment systems. Water, Air Soil Pollut., 142, 187-210 (2003). 628