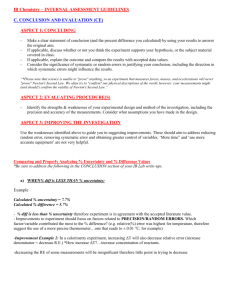

Document

advertisement

ME343

Chapter 5

Distinguish two types of uncertainty

evaluation

Do a design stage uncertainty analysis

Calculate error of a derived variable

Handle uncertainty/error propagation from

multiple sources

Use available information to estimate the

uncertainty range, ux, in the interval estimate

of the true value:

For current analysis, assume that the true

value, x’ is constant (time independent).

Statistical Uncertainty analysis (Type A in NIST terminology) –

based on

◦ – series of repeated measurements, and

◦ – calibration tests

• Judgment based Uncertainty Analysis (Type B in NIST

terminology) – based on

◦ – previous measurement data,

◦ – experience with relevant materials and instruments,

◦ – manufacturer's specifications,

◦ – data provided in calibration and other reports, and

◦ – uncertainties assigned to reference data taken from

handbooks

•

•

•

•

Design stage

Calibration stage

Data acquisition stage

Data reduction stage

We apply design-stage uncertainty analysis

when we don’t have the system yet, or have

not tested it yet.

We either rely on the manufacturer’s data, or

on our own estimates

Major facilities may need to be built and

equipment ordered with considerable lead

time.

It is useful for selecting instruments,

selecting measurement techniques, and

obtaining an appropriate estimate of the

uncertainty likely to exist in the measured

data.

At this point, the measurement system and

associated procedures are but a concept.

Usually little is known about the instruments,

and in many cases they are still pictures in a

catalog.

Design-Stage Uncertainty is made up of two

principle components.

1. Instrument resolution

2.

Instrument uncertainty, uc, (an estimate of

the systematic error for the instrument)

• Treat an error as:

– Precision error if it

can be statistically

estimated in some

manner (data scatter)

– Bias error otherwise

(cannot be directly

discerned by statistical

methods, e.g. By

repeating

measurements).

Calibration

Alternate

(concomitant) Method

Interlaboratory comparisons

Experience

System repeatability and resolution

(measurement system)

Temporal and spatial variations

(measured variable properties)

Operating and environmental conditions

(process)

Measurement repeatability

(measurement procedure and Technique)

A temperature measurement system is

composed of a sensor and a readout devices.

The readout device has a claimed accuracy of

0.6˚C with a resolution of 0.1˚C. the sensor

has an off-the-shelf accuracy of 0.5˚C.

Estimate a design-stage uncertainty in

temperature indicated by this combination.

The design-stage uncertainty is for the combined system is

where (ud )R is the design-stage uncertainty of the

readout device and (ud)s is that of the sensor. In either

case, the individual design-stage uncertainty is found

from

Sensor

The linear displacement of a vehicle due to an applied impact

force is measured with a transducer. Transducer specifications

are:

Input range : 0-5 m

Output range: 0-5 V

Linearity:

± 0.25% reading

Drift:

± 0.05%/˚C FSO

Sensitivity: ± 0.10% FSO

Hysteresis: ± 0.25% reading

The transducer output is indicated on a voltmeter

(accuracy: within ± 0.1% reading; resolution: 10μV). The

expected nominal displacement of the vehicle is to be 4m for

an impact force of 2000± 100N (95% ).

The force-displacement relation can be assumed linear.

Four replications consisting of 10 measurements are

made over the course of one day. The results are given

with the ambient temperature for each run.

Test run

N

1

10

Mean

value

[m]

4.3

2

10

3.8

3

10

4.2

4

10

4.0

At the design-stage, only information known

prior to the test are included:

◦ For the transducer, we estimate the instrument

error from the elemental errors:

eL = ± (0.0025)(4m) = 0.01 m

eH = ± (0.0025)(4m) = 0.01 m

es = ± (0.001)(5m) = 0.005 m

eD = ± (0.005/˚ C)(3˚C)(5m) = 0.0075 m

so that,

The transducer has a sensitivity Kt = 1V/m so

that the voltmeter output can be restated in

terms of displacement [m].

For the voltmeter:

For the transducer-voltmeter system, the designstage uncertainty is:

Now we look at the case of a derived quantity that

is estimated from the measurement of several

primary quantities.

The question that needs to be answered is the

following:

“A derived quantity Q is estimated using a formula

that involves the primary quantities. a1,a2,.....an

Each one of these is available in terms of the

respective best values b1, b2,.....bn and the

respective standard deviations σ1,σ2....σn . What is

the best estimate for Q and what is the

corresponding standard deviation σQ ?”

We have, by definition Q =Q(a1,a2,.......an )

It is obvious that the best value of Q should

correspond to that obtained by using the best

values for the a’s. Thus, the best estimate for

Q given by

Q Q(b1 , b2 , b3 , .....bn )

by definition, we should have:

The subscript i indicates the experiment

number and the ith estimate of Q is given by

Qi = Q(a1i ,a2i ,....ani )

using a Taylor expansion around the best

value as

where the partial derivatives are all evaluated

at the best values for the a’s. If the a’s are all

independent of one another then the errors in

these are unrelated to one another and hence

the cross terms.

The equation can be written as:

Noting that

the above equation can be in the form

the error propagation formula

Two resistors are to be combined to form an equivalent resistance

of 1000. Readily available are two common resistors rated at

50050 and two common resistors rated at 20005%. What

combination of resistors (series or parallel) would provide the

smaller uncertainty in an equivalent 1000 resistance?

Case 1 (series resistors)

RT = R1 + R2

If we use the two 500 resistors, then

ud 1 50 , ud 2 50

The propagatio n of uncertaint y through to RT is estimated by

RT

RT 2 1 2

2

(ud )series = [(

ud1 ) (

) ]

R1

R2

= [(1.u d1 )2 ( 1.ud 2 )2 ] 71

(95%)

Case 2 (paralell resistors)

If we use the two 2000 resistors, then

ud 1 100 , ud 2 100

The propagatio n of uncertaint y through to RT is estimated by

RT

RT 2 1 2

2

(ud )paralell = [(

ud1 ) (

) ]

R1

R2

1

R2

R1 R2

R1

R1 R2

2

2

= [({

}.ud 1 ) ({

}ud 2 ) ] 2

2

2

R1 R2 ( R1 R2 )

R1 R2 ( R1 R2 )

35

(95%)

Heat transfer from a rod of diameter D immersed in a

fluid can be described by the Nusselt number Nu=hD/k,

where h is the heat transfer coefficient and k is the

thermal conductivity of the fluid. If h can be measured

within 7% (95%), estimate the uncertainty in Nu for the

nominal value of h=150 W/m2-K. Let D=200.5 mm and

k=0.62% W/m-K.

uh = (0.07)(150) = 10.5 W/m2-K

uD = 0.0005 m

uk = (0.02)(0.6) = 0.012 W/m-K

We have Nu = f(h,D,k)

1

2

N

N

N

u Nu ( u uh )2 ( u ud )2 ( u uk )2

D

k

h

u Nu

u Nu

h

hD

D

2

2

2

( uh ) ( u D ) ( 2 uk )

k

k

k

1

2

1

2

150

150 x0.005

0.02

2

2

2

(

10.5 ) (

0.005 ) (

0.012 ) 0.4

2

0.6

0.6

0.6

Then, we estimate the Nusselt number here

to be

Nu = hD/k uNu = 5 0.4 (95%)

So, Nusselt number can be determined within

about 8% in this range of values.