Uncertainty Analysis in Measurement & Instrumentation

advertisement

2141-375

Measurement and Instrumentation

Uncertainty Analysis

Measurement Error

True data

Measured value, x

x'

Bias error

x

Precision

error in xi

Measurement number

Uncertainty defines an interval about the measured value within

which we suspect the true value must fall

We call the process of identifying and quantifying errors as

uncertainty analysis.

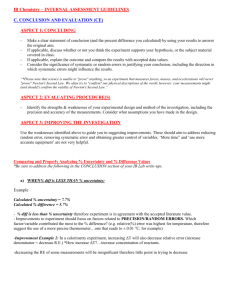

Design-Stage Uncertainty Analysis

Design-stage uncertainty analysis refers to an initial analysis

performed prior to the measurement

Useful for selecting instruments, measurement techniques and

to estimate the minimum uncertainty that would result from the

measurement .

Design-Stage Uncertainty Analysis

u d = u02 + uc2 ( P %)

RSS method for combining error

Design-state uncertainty

ud = u02 + uc2

Interpolation error

u0

Instrument error

uc

Design-Stage Uncertainty Analysis

Zero-Order Uncertainty (Interpolation Error)

Even when all error are zero, the value of the measurand must be

affected by the ability to resolve the information provided by the

instrument. This is called zero-order uncertainty. At zero-order, we

assume that the variation expected in the measurand will be less than

that caused by the instrument resolution. And that all other aspects of

the measurement are perfectly controlled (ideal conditions)

y

u0 = ±1 / 2 resolution (95%)

yo

Instrument Uncertainty, uc

This information is available from the manufacturer’s

catalog

x

resolution

uncertainty

1/2 resolution

Design-Stage Uncertainty Analysis

Specifications: Typical Pressure Transducer

Operation

Input range

Excitation

Output range

Temperature range

Performance

Linearity error eL

Hysteresis error eh

Sensitivity error eS

Thermal sensitivity error eST

Thermal zero drift eZT

0-1000 cm H2O

±15 V dc

0-5 V

0-50oC nominal at 25oC

±0.5%FSO

Less than ±0.15%FSO

±0.25%of reading

0.02%/oC of reading from 25oC

0.02%/oC FSO from 25oC

The root of sum square approach:

erss = e12 + e22 + e32 + L en2

(95%)

Design-Stage Uncertainty Analysis

Example: Consider the force measuring instrument described by the catalog data that follows.

Provide an estimate of the uncertainty attributable to this instrument and the instrument design

state uncertainty.

Force measuring instrument

Resolution:

0.25 N

Range:

0 - 100 N

Linearity:

within 0.20 N over range

Repeatability:

within 0.30 N over range

Known: Instrument specifications

Assume: Values representation of instrument 95% probability

Solution:

Design-state uncertainty

ud = u + u

2

0

u0

½ Resolution = 0.125 N

2

c

u d = ± 0.1252 + 0.36 2 = ±0.38 N

uc

el2 + er2 = ± 0.2 2 + 0.32 = ±0.36 N

Design-Stage Uncertainty Analysis

Example: A voltmeter is to be used to measure the output from a pressure transducer that outputs

an electrical signal. The nominal pressure expected will be ~3 psi (3 lb/in2). Estimate the designstate uncertainty in this combination. The following information is available:

Voltmeter

Resolution:

Accuracy:

Transducer

Range:

Sensitivity:

Input power:

Output:

Linearity:

Repeatability:

Resolution:

10 µV

within 0.001% of reading

±5 psi

1 V/psi

10 Vdc ± 1%

±5 V

within 2.5 mV/psi over range

within 2 mV/psi over range

negligible

Known: Instrument specifications

Assume: Values representation of instrument 95% probability

Solution:

Design-Stage Uncertainty Analysis

Design-state uncertainty

ud =

(ud )2E + (ud )2P

Design-state uncertainty

Design-state uncertainty

(ud )E = (u )

(ud )P = (u0 )2P + (uc )2P

2

0 E

+ (u

)

2

c E

Error Propagation

Computation of the overall uncertainty for a measurement system consisting

of a chain of components or several instruments

Let R is a known function of the n independent variables xi1, xi2 , xi3, …, xiL

R = f ( x1 , x2 , K , xL )

L is the number of independent variables. Each variable contains some

uncertainty (ux1, ux2, ux3,…, uxL) that will affect the result R.

Application of Taylor’s expansion gives, (neglect the higher order term)

R ± ∆R = f ( x1 ± u x1 , x2 ± u x 2 ,..., xL ± u xL ) ≈ f ( x1 , x2 ,..., xL ) +

∂f

∂f

∂f

u x1 +

u x 2 + ... +

u xL

∂x1

∂x2

∂xL

The best estimate value, R’

R' = R ± u R ( P%)

Where R = f ( x1 , x2 ,..., xL )

Error Propagation

The combination of uncertainty of all variables (probable estimate of uR)

2

2

∂f

∂f

∂f

u R = ±

u x1 +

u x 2 + K +

u xL

∂x1 ∂x2

∂xL

=±

2

L

2

(

)

θ

u

∑ i xi

( P %)

i =1

Where θi is the sensitivity index relate to the uncertainty of xi

θi =

∂f

∂xi

Error Propagation

Example: For a displacement transducer having a calibration curve y = KE, estimate the

uncertainty in displacement y for E = 5.00 V, if K = 10.10 mm/V with uk = ±0.10 mm/V and uE =

±0.01 V at 95% confidence

Known: y = KE

E = 5.00 V

K = 10.10 mm/V

uE = 0.01 V

uk = 0.10 mm/V

Solution: Find uy

y ' = y ± u y = KE ± u y

u y = ± (θ E u E ) + (θ K u K )

2

θE =

∂y

=K

∂E

uE = 0.01 V

uy = ±

2

θK =

∂y

=E

∂K

uK = 0.10 mm/V

(Ku E )2 + (Eu K )2

= ± (10.10 mm/V × 0.01 V ) + (5 V × 0.10 mm/V ) = ±0.51 mm

2

2

Sequential Perturbation

A numerical approach can also be used to estimated the propagation of

uncertainty. This refers to as sequential perturbation. This method is

straightforward and uses the finite difference to approximate the

derivatives (sensitivity index)

1) Calculate the average result from the independent variables

R = f ( x1 , x2 ,..., xL )

2) Increase the independent variables by their respect uncertainties

and recalculate the result based on each of these new values. Call

these values Ri+

R1+ = f ( x1 + u1 , x2 ,..., xL ),

R2+ = f ( x1 , x2 + u 2 ,..., xL )

RL+ = f ( x1 , x2 ,..., xL + u L )

3) Decrease the independent variables by their respect uncertainties

and recalculate the result based on each of these new values. Call

these values Ri−

Sequential Perturbation

R1− = f ( x1 − u1 , x2 ,..., xL ),

R2− = f ( x1 , x2 − u2 ,..., xL )

RL− = f ( x1 , x2 ,..., xL − u L )

4) Calculate the difference for each element

δRi+ = Ri+ − R

δRi− = Ri− − R

5) Finally, evaluate the approximation of the uncertainty contribution from

each variables

δRi =

δRi+ + δRi−

2

≈ θ i ui

The uncertainty in the result

2

u R = ± ∑ (δRi )

i =1

L

1/ 2

Error Propagation

Example: For a displacement transducer having a calibration curve y = KE, estimate the

uncertainty in displacement y for E = 5.00 V, if K = 10.10 mm/V with uk = ±0.10 mm/V and uE =

±0.01 V at 95% confidence

Known: y = KE

E = 5.00 V

K = 10.10 mm/V

uE = 0.01 V

uk = 0.10 mm/V

Solution: Find uy

y ' = y ± u y = KE ± u y

u y = ± (δRE ) + (δRK )

2

2

y = KE = (10.10 )(5) = 50.50 mm

i

1

2

ui

x i +u i

x i -u i

Ri+

Ri-

δRi+

δRi-

δRi

5

0.01

5.01

4.99

50.60

50.40

0.10

-0.10

0.10

10.1

0.1

10.20

10.00

51.00

50.00

0.50

-0.50

0.50

xi

E

K

Error Sources

Steps in measurement process

1) Calibration

2) Data-acquisition

3) Data-reduction (Analysis)

Calibration

error

e11, e12, K

Data-acquisition

error

e21, e22, K

Data-reduction

error

e31, e32, K

eij

j = Elemental error

i = Error source group

i = 1 for Calibration Error

i = 2 for Data-acquisition Error

i = 3 for Data-reduction Error

Calibration Error Source Group

Element (j)

1

2

3

4

5

Etc.

Error Source

Primary to interlab standard

Interlab to transfer standard

Transfer to lab standard

Lab standard to measurement system

Calibration technique

Data-Acquisition Error Source Group

Element (j)

1

2

3

4

5

6

7

8

9

Etc.

Error Source

Measurement system operating conditions

Sensor-transducer stage (instrument error)

Signal conditioning stage (instrument error)

Output stage (instrument error)

Process operating conditions

Process installation effects

Environmental effects

Spatial variation error

Temporal variation error

Data-Reduction Error Source Group

Element (j)

1

2

Etc.

Error Source

Calibration curve fit

Truncation error

Multiple-Measurement Uncertainty Analysis

This section develops a method for the estimate of the uncertainty in the

value assigned to a measured variable based on repeated measurements

The procedure for a multiple-measurement uncertainty analysis

e1j=P1j+B1j

e2j=P2j+B2j

e3j=P3j+B3j

Calibrate

e11, e12 ,...

Data acquisition

e21, e22 ,...

Data reduction

e31, e32 ,...

Identify the elemental errors in each of the three source groups

(calibration, data acquisition, and data reduction)

Estimate the magnitude of bias and precision error in each of the

elemental errors

Estimate any propagation of uncertainty through to the result

Multiple-Measurement Uncertainty Analysis

Consider the measurement of variable, x which is subject to elemental

precision errors, Pij and bias, Bij in each of three source groups. Let i = 1, 2,

3 refer to the error source groups ( calibration error i = 1, data acquisition

error i = 2, data-reduction i = 3) and j = 1,2,…,K refer to each of up to any K

error elements of error eij

Source Precision index Pi

[

Pi = Pi12 + Pi 22 + ... + Pik2

Measurement Precision index P

[

P = P12 + P22 + P32

Source Bias limit Bi

]

1/ 2

]

1/ 2

[

Bi = Bi21 + Bi22 + ... + Bik2

Measurement Bias limit B

[

B = B12 + B22 + B32

i = 1, 2, 3

]

1/ 2

]

1/ 2

i = 1, 2, 3

Multiple-Measurement Uncertainty Analysis

The measurement uncertainty in x, ux

u x = B 2 + (tv ,95 P )

2

(95%)

The degrees of freedom, v (Welch-Satterthwaite formula)

2

3 K 2

∑∑ Pij

i =1 j =1

v= 3 K

∑∑ Pij4 / vij

(

i =1 j =1

)

Multiple-Measurement Uncertainty Analysis

Measurement uncertainty, ux

[

u x = B 2 + (tv ,95 P )

]

2 1/ 2

Measurement precision index, P

[

(95%)

Measurement bias limit, B

]

[

2 1/ 2

3

P = P12 + P22 + P

B = B12 + B22 + B32

Source precision index, Pi

[

1/ 2

Source bias limit, Bi

]

[

2 1/ 2

ik

Pi = Pi12 + Pi 22 + ... + P

]

Bi = Bi21 + Bi22 + ... + Bik2

eij=Pij+Bij

Identify elemtal errors

in measurement, eij

Measurand, x

]

1/ 2

Multiple-Measurement Uncertainty Analysis

Example: After an experiment to measure stress in a load beam, an uncertainty analysis reveals

the following source errors in stress measurement whose magnitude were computed from

elemental errors

B1 = 1.0 N/cm2

B2 = 2.1 N/cm2

B3 = 0 N/cm2

P1 = 4.6 N/cm2

P2 = 10.3 N/cm2

P3 = 1.2 N/cm2

v1 = 14

v2 = 37

v3 = 8

If the mean value of the stress in the measurement is 223.4 N/cm2, determine the best estimate of

the stress

Known: Experimental error source indices

Assume: All elemental error have been included

Solution: Find uσ

Measurement uncertainty, ux

[

u x = B 2 + (tv ,95 P )

Measurement precision index, P

[

]

2 1/ 2

3

P = P12 + P22 + P

]

2 1/ 2

(95%)

Measurement bias limit, B

[

B = B12 + B22 + B32

]

1/ 2

Propagation Uncertainty Analysis to a result

Consider the result, R which is determined from the function of the n independent

variables xi1, xi2 , xi3, …, xiL

R' = R ± u R ( P%)

The measurement uncertainty, uR

u R = BR2 + (tv ,95 PR )

2

where

PR = ±

(95%)

L

∑ [θi Pxi ]2

BR = ±

i =1

L

∑ [θ B

i

i =1

The degrees of freedom, v

2

L

2

∑ [θ i Pxi ]

v = L i =1

4

∑ [θ i Pxi ] / vxi

{

i =1

}

2

]

xi

Propagation Uncertainty Analysis to a result

Example: The density of a gas, ρ, which is believed to follow the ideal gas equation of state, ρ =

p/RT, is to be estimated through separate measurements of pressure, p, and temperature, T. the

gas is housed with in a rigid impermeable vessel. The literature accompanying the pressure

measurement system states an accuracy to within 1% of the reading an that accompanying the

temperature measuring system suggest 0.6oR. Twenty measurements of pressure, Np = 20, and

ten measurements of temperature, NT = 10, are made with the following statistical outcome:

p = 2253.91 psfa

S p = 167.21 psfa

T = 560.4o R

ST = 3.0o R

Where psfa refers to lb/ft2 absolute. Determine a best estimate of the density. The gas constant is

R = 54.7 ft lb/lbm oR

Known:

p , S p , T , ST

ρ = P / RT R = 54.7 ft lb/lbm o R

Assume: Gas behaves as an ideal gas

Solution: Find

ρ ' = ρ + uρ

Propagation Uncertainty Analysis to a result

[

u ρ = B 2 + (tv ,95 P )

]

[(θ P ) + (θ P ) ]

2 1/ 2

(95%)

where v =

p

(θ P )

4

p

B = ± (θ p B p ) + (θT BT )

2

where

2

P = ± (θ p Pp ) + (θT PT )

2

ρ = P / RT R = 54.7 ft lb/lb m o R

θp =

∂ρ

1

=

∂p RT

2 2

2

θT =

∂ρ

p

=−

∂T

RT 2

2

p

p

T

T

/ v p + (θ T PT ) / vT

4