Advanced, Low-Pressure-Drop, Tower Inlet Design

G.B. Watson

L.J. Chaney

Babcock & Wilcox/McDermott Technology, Inc.

Alliance, Ohio, U.S.A.

Presented to:

EPRI-DOE-EPA Combined Utility Air Pollutant Control

Symposium

August 16-20, 1999

Atlanta, Georgia, U.S.A.

Abstract

Wet flue gas desulfurization (FGD) scrubbers are a major

product line of The Babcock & Wilcox Company (B&W). To

remain competitive in the FGD market, B&W’s Environmental

Engineering has been developing technology to improve performance and reduce operating and capital costs of FGD systems. B&W, in cooperation with the McDermott Technology,

Inc. (MTI) Research and Development Division (a B&W affiliate), continued an on-going program to improve FGD scrubber

fluid mechanics. The goals of the program, which is in its seventh year, are to improve the product design and marketability

by reducing scrubber cost and minimize the technical risks. For

cost reduction, the program focuses on developing compact

scrubber designs to reduce the material and fabrication costs.

The technical risks are minimized by testing and evaluating new

concepts and ideas in a one-eighth scale wet scrubber hydraulic

model. The cumulative results of previous years’ development

efforts is an advanced scrubber design that is 20% smaller than

the base-technology wet scrubber. The focus of the program

this year is on testing a novel, low-pressure-drop tower inlet.

Some of the results of this testing are summarized in this paper.

Introduction

Since 1992, B&W and MTI have been engaged in a development program to study, understand, and improve the fluid mechanics of FGD systems. The objective of this effort is to improve the product line and reduce the capital and operating costs

of the B&W wet scrubber tower. The B&W FGD tower uses a

counterflow spray design to promote intimate and uniform contact between the gas and liquid phases in the scrubber and maximize SO2 removal at a given liquid to gas ratio. The focus of

the development program is an experimental approach to optimize wet scrubber flow characteristics using a reduced-scale

Babcock & Wilcox

W.F. Gohara

Babcock & Wilcox

Barberton, Ohio, U.S.A.

BR-1689

RDTPA 99-09

hydraulic model that simulates full-scale units and also allows

the designer full access to view the complex two-phase flow

regions within the tower.

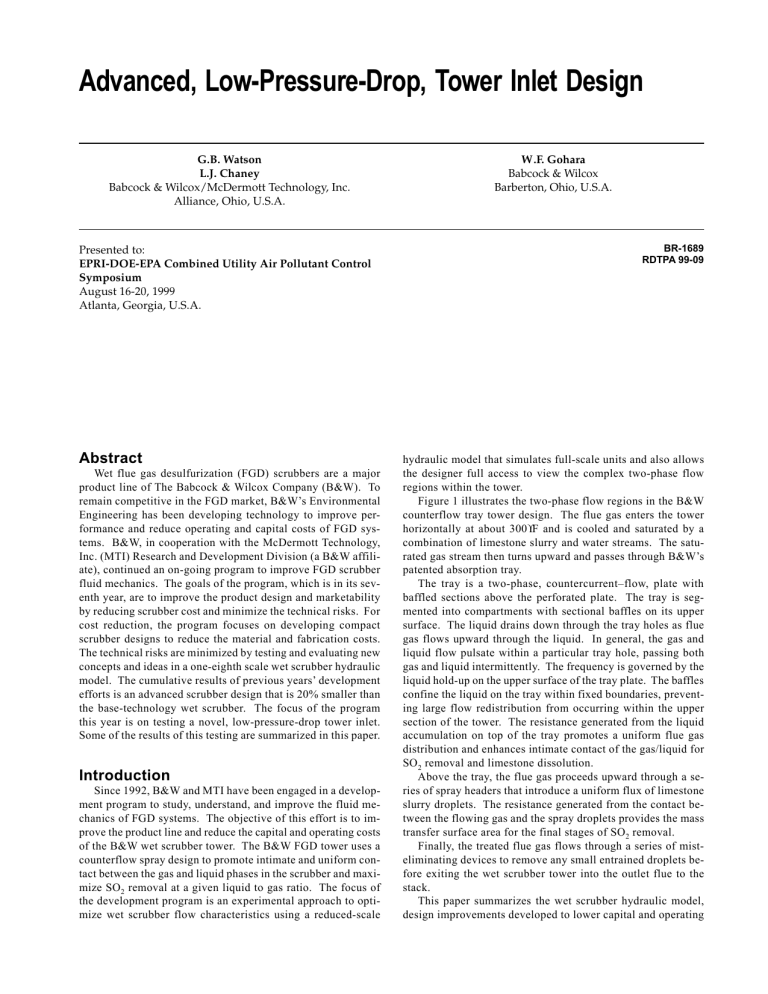

Figure 1 illustrates the two-phase flow regions in the B&W

counterflow tray tower design. The flue gas enters the tower

horizontally at about 300°F and is cooled and saturated by a

combination of limestone slurry and water streams. The saturated gas stream then turns upward and passes through B&W’s

patented absorption tray.

The tray is a two-phase, countercurrent–flow, plate with

baffled sections above the perforated plate. The tray is segmented into compartments with sectional baffles on its upper

surface. The liquid drains down through the tray holes as flue

gas flows upward through the liquid. In general, the gas and

liquid flow pulsate within a particular tray hole, passing both

gas and liquid intermittently. The frequency is governed by the

liquid hold-up on the upper surface of the tray plate. The baffles

confine the liquid on the tray within fixed boundaries, preventing large flow redistribution from occurring within the upper

section of the tower. The resistance generated from the liquid

accumulation on top of the tray promotes a uniform flue gas

distribution and enhances intimate contact of the gas/liquid for

SO2 removal and limestone dissolution.

Above the tray, the flue gas proceeds upward through a series of spray headers that introduce a uniform flux of limestone

slurry droplets. The resistance generated from the contact between the flowing gas and the spray droplets provides the mass

transfer surface area for the final stages of SO2 removal.

Finally, the treated flue gas flows through a series of misteliminating devices to remove any small entrained droplets before exiting the wet scrubber tower into the outlet flue to the

stack.

This paper summarizes the wet scrubber hydraulic model,

design improvements developed to lower capital and operating

1

MIST ELIMINATION

REGION

OUTLET FLUE

TREATED

FLUE GAS

GAS

FLOW

SPRAY REGION

2nd MIST ELIMINATOR

OVERSPRAYS

1st MIST ELIMINATOR

UNDERSPRAY

SPRAYS

GAS

FLOW

TRAY

TRAY REGION

FLUE GAS

BELOW TRAY

SPRAY

INLET FLUE

INLET REGION

GAS FLOW

LIQUID COLLECTION

TANK

Figure 1

Wet scrubber two-phase fluid mechanics.

Figure 2

costs, and the advanced, low-pressure-drop, tower inlet designs

(the focus of our more recent testing in the hydraulic model).

Wet Scrubber Hydraulic Flow Model

Figure 2 is a photograph of the wet scrubber hydraulic model

facility. The model is one-eighth scale of a typical countercurrent-flow scrubber design offered commercially by B&W.

Air and water at ambient temperature are used in the hydraulic test facility to simulate the flue gas and limestone slurry

respectively. Significant air fan and water pump capabilities

are available to test a wide range of superficial tower gas velocities of 4 to 25 ft/s with spray liquid fluxes of 10 to 90 gpm/

ft2.

During the initial phase of the development program, considerable effort was spent developing modeling criteria from

basic fluid mechanics theory to establish the necessary relationships between the full-size field units and the one-eighth-scale

model. Previous publications contain further details of the developed model criteria along with the field data used to verify

methodology (1,2,3).

Wet scrubber hydraulic model during operation.

flow and by applying proper high-velocity mist elimination devices. The reduction in tower height was achieved by using a

B&W-patented interspacial header design (Figure 3).

The interspacial spray header design doubles the number of

spray nozzles at a particular level by locating the main header

outside the tower and penetrating the tower with the branches

at several locations around the scrubber perimeter. This approach reduces the number of spray levels, for example, from

four to two and reduces the tower height by a minimum of 10

feet. The hydraulic model was used to evaluate the pressure

drop of this new design and the changes in the gas and liquid

behavior as a result of the consecutive restriction and expansion in the gas flow area in the spray zone. The study showed

that the pressure drop of the spray zone did not change compared with the two separate header designs, because the anticipated increase in the spray-zone pressure drop due to inertial

mechanisms and area restrictions was offset by the reduction in

the mixture static height pressure drop. Therefore, the

Conventional Design

∆P spray (2 headers) = 1.12 inches H20

Interspacial Design

∆P spray = 1.08 inches H20

Wet-Scrubber Design Improvements

Our development effort over the past several years resulted

in significant cost savings in material of construction, simplified fabrication, and expanded the operating range of modern

scrubber design. The design improvements that have been

achieved in the hydraulic model demonstrated that a reduction

of 20% in diameter and several feet of tower height are achievable.

Reducing tower diameter was achieved by increasing superficial absorber gas velocity from the conventional 10 ft/s to more

than 15 ft/s. The higher tower gas velocity was obtainable by

optimizing the B&W tray to uniformly distribute the tower gas

2

Figure 3

Compact spray header design.

Babcock & Wilcox

interspacial spray header offers capital cost savings due to reduced tower height without penalties in operating cost due to

increased pressure drop.

Field data of full-scale commercial units confirmed the hydraulic model findings without sacrificing the absorber’s removal efficiency.

The other design improvement modified the tower inlet by

redesigning the awning that controls the formation of solid buildup in the absorber inlet at the wet/dry interface. The awning

directs the contact between the gas and the liquid into a location in the middle of the absorber domain away from the inlet

flue. Figure 4 shows the original and the improved awning designs. The awning design shown in Figure 4 was the first step

to further develop other inlet configurations to reduce the absorber pressure drop and tower height while still protecting the

inlet from solids formation at the wet/dry interface.

New Inlet Design

The wet scrubber inlet provides a transition between the hot

inlet flue gas at a velocity of 50 ft/s and the wet scrubber tower

that operates at a velocity ranging from 10 to more than 15 ft/s.

The key design requirement of the tower inlet is to quench the

flue gas to saturation temperature while keeping the wet/dry

interface boundary away from the inlet flue surfaces.

If the limestone slurry is drawn into the inlet flue due to

eddy currents or to poor distribution of the incoming gas and

contacts the hot inlet flue surface, the liquid phase of the slurry

evaporates and solids deposition occurs. Further growth of these

solids restricts the flue gas inlet flow area, increases the system’s

flow resistance, and may force an unscheduled outage for cleaning and solids removal.

B&W uses the awning as shown earlier in Figure 4 to control the wet/dry interface to prevent formation of hard solid deposition on the surfaces of the inlet flue.

Besides controlling the wet/dry interface, the flue inlet and

the transition to the tower must also effectively decelerate the

flue gas from the high inlet flue velocity to the lower tower

velocity without an unnecessary increase in pressure drop. Also,

an ideal inlet transition would not only provide an efficient decrease in velocity but would turn the flue gas 90° upward, entering the tray with a uniform distribution.

Figure 5 shows the commonly offered inlet design that uses

the low-pressure-drop inlet shown in Figure 4. When this inlet

design was used on a flared tank, the inlet transition was located above the flare in the cylindrical section of the liquid colFinal Design

∆P Inlet = 1.5 inches H 20

Initial Design

∆P Inlet = 2.2 inches H2 0

Flue Gas

Flow

Flue Gas

Flow

Figure 4

Wet scrubber inlet design for low pressure drop.

Babcock & Wilcox

Figure 5

Conventional inlet.

lection tank. This design is satisfactory at the conventional

absorber gas velocities. At these gas velocities, the gas momentum in the spray zone and in the gas leaving the inlet is

close enough to provide an even gas flow distribution at the

face of the mist eliminators. At high absorber gas velocities,

the absorber diameter becomes small and the designer has to

decide between one of the two options for the absorber inlet:

• Maintain the same inlet flow area and increase the gas

velocity to accommodate the physical constraints of the small

absorber diameter. As a result, the momentum of the gas leaving the inlet increases more significantly than the spray zone

gas momentum. The relatively large gas momentum leaving

the inlet causes significant distortion in the gas flow, which cannot be corrected by the spray-zone resistance before the gas flow

enters the mist eliminators. Local distortions in gas velocity

entering the mist eliminators that exceed the critical velocity of

the mist eliminator result in excessive liquid carry-over to the

stack.

• Maintain the same standard inlet gas velocity and increase

the inlet flow area. If the inlet flue flow area is adjusted to

provide the conventional standard velocity, the aspect ratio

(height/width) of the inlet flue would have to increase. The

increase in the tower height would reduce the benefits and the

advantages gained by high tower velocity.

3

Straight wall inlet

transition

P inlet = 1.5 in H 2 O

References

New flared inlet

transition

P inlet = 1.0 in H 2O

Awning

Flue gas

flow

Figure 6

Flue gas

flow

New flared wet scrubber inlet.

The increase in the resistance as the tower velocity increases

from 15 ft/s to 20 ft/s is due to higher-than-normal inlet flue

velocity. Therefore, to take advantage of the increased tower

velocity and the reduction in absorber diameter without an increase in tower height, the width of the inlet flue has to be increased, thereby decreasing the inlet flue aspect ratio.

The new inlet design is shown in Figure 6. The new design

positions the inlet in the flared tower transition section between

the lower larger diameter liquid recirculation tank and the upper smaller diameter absorption section of the tower. As a consequence of locating the inlet in the flare, the top surface of the

inlet flue is not directly above the bottom surface, but extends

beyond the lower surface of the inlet flue. The advantage of

having this extension is that it provides a natural protection for

the inlet as it controls the wet/dry interface boundary the same

way that the awning did in the conventional straight-wall inlet.

The amount of this extension depends on the angle of the flared

section.

Hydraulic model tests of the new inlet design have confirmed

a lower pressure drop than the straight-wall inlet design. Visual observation of the inlet and the liquid flow also confirmed

that when operating the absorber over a wide range of gas velocities and spray liquid flux there was no deposition or rollback of the absorber liquid on the surfaces of the inlet flue.

Conclusions

The results of the hydraulic model tests have confirmed that

the new inlet positioned in the flare section of the tower has

lower pressure drop than an inlet with an awning structure and

results in no liquid deposition on the inlet. This new inlet enables the next generation of wet scrubbers to achieve tower velocities in the 15 to 20 ft/s range with minimum absorber pressure-drop resistance.

4

1. T.W. Strock, P. Dykshoorn, M.J. Holmes, and W.F.

Gohara, “Experimental Approach and Techniques for the Evaluation of Wet FGD Scrubber Fluid Mechanics,” presented at the

EPRI/EPA/DOE 1993 SO 2 Control Symposium, Boston, Massachusetts (August 1993).

2. T.W. Strock and W.F. Gohara, “Use of Hydraulic Models

to Identify and Resolve Design Issues in FGD Systems,” presented at the EPRI 1995 SO 2 Control Symposium, Miami,

Florida (March 1995).

3. W.F. Gohara and T.W. Strock, “New Perspective of Wet

Scrubber Fluid Mechanics in an Advanced Tower Design,” presented at the EPRI/EPA/DOE Combined Utility Air Pollutant

Control Symposium, Washington D.C. (August 1997).

Copyright © 1999 by The Babcock & Wilcox Company,

All rights reserved.

No part of this work may be published, translated or reproduced in any

form or by any means, or incorporated into any information retrieval

system, without the written permission of the copyright holder.

Permission requests should be addressed to: Market Communications,

The Babcock & Wilcox Company, P.O. Box 351, Barberton, Ohio,

U.S.A. 44203-0351.

Disclaimer

Although the information presented in this work is believed to be

reliable, this work is published with the understanding that The

Babcock & Wilcox Company and the authors are supplying general

information and are not attempting to render or provide engineering or

professional services. Neither The Babcock & Wilcox Company nor any

of its employees make any warranty, guarantee, or representation,

whether expressed or implied, with respect to the accuracy,

completeness or usefulness of any information, product, process or

apparatus discussed in this work; and neither The Babcock & Wilcox

Company nor any of its employees shall be liable for any losses or

damages with respect to or resulting from the use of, or the inability to

use, any information, product, process or apparatus discussed in this

work.

Babcock & Wilcox