American Airlines Tulsa and Transport Workers Union Case Study

advertisement

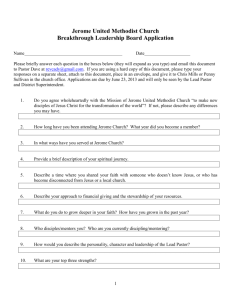

American Airlines and Transport Workers Union From Conflict to Collaboration Michael Sokoloff, PhD Synopsis: Stories of union-management conflict generally draw more attention and bigger headlines than reports of collaboration. If the opposite were true, the accounts of collaboration between American Airlines and its labor unions would be much better known. The author here recounts how American Airlines and one of its unions overcame a history of growing distrust and in this example worked together to create a $500 million return in two years’ time. A Rough Start Stories of union-management conflict generally draw more attention and bigger headlines than reports of collaboration. If the opposite were true, the accounts of collaboration between American Airlines and its labor unions would be much better known. What makes this story of collaboration even more remarkable is the level of extreme distrust and animosity which served as the starting point for a unionmanagement partnership. In April 2003, members of the pilots’, flight attendants’, and mechanics’ unions did the unthinkable by ratifying re-structured collective bargaining agreements and surrendering $1.8Billion in yearly concessions to American Airlines management. Only weeks earlier, employees were informed by American’s CEO Don Carty that the company would immediately file for bankruptcy if any of the 3 unions rejected the concessions demanded by the company. There were no good options for the unions. Union leaders had reviewed the company’s books with their own experts and concluded the threat of bankruptcy was very real and likely to occur. Collectively, union leaders also believed their choice was the lesser of two evils, with an extended concessionary contract being the slightly better choice over having a bankruptcy judge and a court appointed committee of creditors making decisions about union wages, benefits, and working conditions. When union members originally voted to approve the “give-backs” in their contracts, they did so with the knowledge that American’s managers and non-union employees were being forced to accept similar cuts to their salaries and benefits. However, almost immediately after the three unions gave their approval of the concessionary agreements, it was revealed Mr. Carty failed to adequately disclose substantial retention bonuses arranged for the top 45 executives of the company which included $41Million in pension benefits funded and protected even in the case of bankruptcy. This revelation incited an uproar resulting in Mr. Carty’s immediate resignation. ©2014 Overland Resource Group 1 Mr. Carty was replaced by Gerard Arpey, American’s President and COO and a longtime employee who, prior to accepting the job, met with leaders of the 3 unions, informing them that without their support it, he would not accept the job. Union leaders expressed their willingness to work with Mr. Arpey. Arpey later pledged, “As your new CEO, I am up to the task. I will always do what is right. Working with our unions and all of our employees, together we will put American Airlines back on top."1 A CEO’s Challenge Shortly after he assumed the role of CEO, consultants from Overland Resource Group were invited to meet with Mr. Arpey and his management team. Arpey asked each of his managers what one word would describe their personal view of the relationship between the company and its labor unions, posting their answers on a board at the front of the room - “hostile,” “belligerent,” “confrontational,” “destructive” and so on. Then, he asked a second question, “In one word can you describe the kind of relationship you’d like to have with our unions? Managers’ responses included the words "trust," "partnership," and "cooperation." Talking about their current view of the labor relationship, Arpey told the group “I’m not working someplace where that’s the way people feel about each other.” "I'm not sure yet how we're going to do it," he told the group. "But we've got to build a bridge from this list to that one."2 Mr. Arpey then declared that even with the hundreds of years of experience in the room, they still hadn’t found a way to create the positive relationship they wanted and that it was time to bring in some expert help. Management and Union Leaders Explore “Working Together” In August 2003, Overland met with company and union leaders and explored ways to facilitate the parties toward a more constructive set of relationships. In a series of separate conversations with the senior leaders of American, the Transport Workers Union (TWU), Allied Pilots Association (APA), and Association of Professional Flight Attendants (APFA), members of the Overland team assessed the interest and readiness of each party for a more collaborative approach to conducting unionmanagement relations. While union and management leaders expressed real doubts and concerns about their counterparts, they agreed to the formation of a National Joint Leadership Team (NJLT) that included CEO Gerard Arpey, six senior operating vice presidents along with key officers of the three unions, including Jim Little (Air Transport Division VP – TWU), John Darrah (President of APA) and John Ward (President of APFA). This leadership group elected to convene monthly, in half-day meetings to share financial information, to discuss critical business issues facing the airline, and to explore opportunities to work together on issues of mutual interest and gain. Their first mission was to provide all American employees with the crucial business information that had only recently been shared with union leaders because the company needed a concessionary agreement. ©2014 Overland Resource Group 2 Tulsa Maintenance Base launches Working Together In the winter of 2003 and early 2004 the NJLT invited local union and management leaders in 5 airports and 2 aircraft maintenance facilities, which included the 7000+ employee Tulsa Maintenance and Engineering Base, to prototype a union-management collaboration process in their locations. Union and management leaders in each location met and agreed to begin identifying and collaborating on issues of mutual interest. Tulsa leaders initiated their exploration into “working together” by establishing a “Core Team” comprised of the base’s top managers and TWU Local 514’s elected officers. As with the formation of the NJLT, both parties entered the arrangement with considerable skepticism about their counterparts’ trustworthiness and capacity to work together. Even so, the Core Team authorized Overland to interview a cross section of all Tulsa Base employees in focus groups in which employees were invited to share their opinions, concerns, and hopes. Drawing on feedback collected from focus groups, the Core Team prioritized issues and established five union-management task forces to focus on the more urgent problems which, if resolved, could trigger an immediate improvement in working conditions, morale, and the poor state of the unionmanagement relationship. The task forces quickly demonstrated union and management could make progress on issues of mutual interest. They began by sharing credible, timely news and information that had typically been withheld from employees. Employees at all levels were enlisted to gather and share critical information. The two parties started using jointly developed business cases to drive insourcing and outsourcing decisions intent on improving productivity, profitability, and job security. There was a new energy on both sides inspiring the resolution of hundreds of long-standing grievances and disciplinary issues. Morale improved as employees recognized their opinions were influencing more positive solutions to a set of problems ranging from the best ways to improve quality and productivity to correcting the way payroll exceptions were mismanaged. A Question of Survival During the spring and summer of 2004, even with changes in the elected leadership of Local 514, union and management gained more confidence in the collaboration process and developed a degree of trust in each other. However, a bigger concern was coming into focus for all employees in the Tulsa Maintenance Base. AA’s corporate leaders were sending the message that in light of AA’s severe cash challenges, unless the base could significantly improve its cost structure, maintenance work would have to be outsourced to MROs doing the same work as Tulsa for almost half the cost and Tulsa base would be shut down. The threat of outsourcing became very real. Most other airlines, such as United, had already outsourced their heavy maintenance; and Wall Street analysts were pressing hard on Arpey’s management team to stop bucking the trend toward outsourcing as a means to reduce operating costs. Why not send the work to MRO’s (maintenance, repair and overhaul stations) in Central America or Asia and save millions? ©2014 Overland Resource Group 3 Tulsa’s managers and union leaders recognized their shared fate. Management realized they couldn’t improve productivity without addressing the union’s job security issues, and the union realized they couldn’t address their job security concerns without improving productivity. While the two parties had some early success collaborating, they had no ready answer as to how they could drive costs down low enough to keep their work. Charting a New Course January 2005 marked a first for Tulsa’s Maintenance Base as 50 management and union leaders came together for 3 days to dissect the business challenges facing their base and figure out what to do about it. Sr. VP of Operations, Bob Reding, presented an in-depth analysis of AA’s airline competitors, the MRO industry, and the opportunities for Tulsa to compete in the MRO market. Carmine Romano, VP of Tulsa base, appealed to his managers and to union leaders “The only people that can provide our officers with justifiable business reasons to keep our overhaul organization are you and I. If we cannot provide justification for our existence, there will come a time when we no longer exist. Those are strong words that send a chill down my back.” With over 700 laid off mechanics on the street, TWU Local 514 president Dennis Burchette expressed his concerns about the threat to union jobs saying, “We have choices. We can choose to do nothing. We know where that leads — the evidence is all around us.” At the end of the 3 day meeting, the group of 50 had agreed on a goal - “To lead Tulsa to become a profit center by the end of 2006 achieving a measurable goal of $500 million by year-end 2006 through: an employee-involved culture, improved turn times, returning additional aircraft to revenue service, cost savings and customer contract work.” The consensus was that carving significant costs out of the $1Billion+ organization would shift the perception of Tulsa from a liability to a competitive asset. Those in the meeting understood their “big, hairy, audacious goal” of $500 million was unachievable without a dramatic departure from the ways they had always worked to maintain AA’s fleet. Their intent was to disrupt the attitude that “we’ve always done it this way” and encourage a mindset of invention. The leaders took their first steps to achieving their objective by organizing themselves into joint union/management teams formed to work on critical problems and develop strategies in the areas of technology, job security, turn time reduction, performance measures, marketing and sales, and culture change. Targeting a Breakthrough One of the early advances from the work teams came from the Turn Time Team. The Turn Time Team was jointly led by AA manager Ken Durst and TWU Chairman of Maintenance Kevin Hammack. The team’s goal was to find ways to reduce costs by shortening the amount of time required to overhaul aircraft and return them to service. The team quickly concluded they could make the most progress if they targeted an improvement plan on their largest fleet, the MD-80 aircraft. At the time, American had about 330 MD-80s in their fleet and each jet was required by the FAA to undergo a complete overhaul (“heavy check”) approximately every 5 years. ©2014 Overland Resource Group 4 The airline’s cost for overhauling an MD-80 was a little more than double what some competitor MRO’s charged. Each time an MD-80 flew into Tulsa for a heavy check, the plane would sit in one of 7 docks (scaffolding structures that surround the airplane)) staffed with about 120 mechanics and 5 supervisors for anywhere from 20 to 35 days. Turn Time Team members knew they had to close an enormous gap if they wanted to make the case for keeping the work in-house. The team also recognized they needed the support of mechanics, stock clerks, staff, supervisors and managers, and union reps if Tulsa maintenance base was going to produce a market competitive product. Overland Resource Group’s consultants met with the Turn Time Team to explore the potential of Breakthrough Work Design as a method for improving MD-80 turn time. Breakthrough Work Design® is a highly disruptive collaborative process that allows organizations to completely rethink how they get work done, enabling them to make radical improvements to their key business processes. The team agreed to apply the Breakthrough process to their MD-80 challenge. The Breakthrough Session With design support and facilitation from Overland, in March 2005 the turn-time team hosted a 4 day Breakthrough Work Design Session attended by 170 participants, including mechanics, stock clerks, engineers, planners, supervisors and others representing all aspects of the MD80 aircraft overhaul business. Over the four days the group was challenged to set a breakthrough target; a goal which they instinctively knew was achievable without necessarily knowing how they would achieve it. The idea of Breakthrough is to challenge groups to think beyond their “business as usual” approaches to invent what is necessary by working backward from an achievable objective. If a group in a Breakthrough session acknowledges that “we think our goal is possible, but we’ll have to invent a way to make it happen,” they are on the right track. After 4 days, the group of 170 had set a breakthrough goal of reducing MD-80 turn time heavy check by 55% and cutting the unit cost by 50%. A Heavy check is a complete overhaul of the aircraft that requires anywhere from 20,000 to 30,000 man-hours of labor and involves careful removal, repair, rebuild and final inspection of everything from the landing gear and jet engines to the lavatories. People are amazed when they look inside one of these jets once it’s been torn down for repair, usually saying something like “Wow, it’s an empty tube!” The breakthrough participants also established 7 work stream teams to drive the development and rapid cycle prototyping of breakthrough ideas for achieving the Breakthrough Goal. Mike Hunter of the Overland Resource Group explained, “The rapid cycle change challenges work stream teams to make progress every week by using the minimum criteria to set up and test prototypes, then quickly correcting and/or re-prototyping. The rapid cycle idea is to build fast, but refine and perfect later.” The group of 170 agreed to keep their teams moving and to reconvene at 30, 60 and 90 day intervals to check signals and coordinate action between teams. The “Breakthrough” teams included: · Flow Team: Charged with examining and re-designing the workflow to a target of 12 days for a heavy check while improving labor efficiency and eliminating waste. · Manpower Team: Develop and test staffing and crew designs supporting the redesigned workflow. ©2014 Overland Resource Group 5 · · · · · Point of Use Team: Create point of use tools and materials kits for critical routine and nonroutine overhaul work. Communication Team: Develop and test communication processes and vehicles necessary to elevate employee engagement and support the effectiveness of the new workflow. Standardization Team: Determine the best facility design for the 12 day check by designing dock layout plans in a manner that coordinated overhaul on the major sub-assemblies being completed in the back-shops. Culture Team: Develop approaches to establish a culture of employee engagement and union/management collaboration. Logistics Team: Evaluate and synchronize logistics of equipment, negotiate and coordinate staff groups’ (e.g. engineering, planning, etc.) and back shops’ support for the redesigned workflow. Forwarding Breakthrough The work stream teams were tasked to meet as frequently as necessary to maintain rapid progress toward the breakthrough goal. Some teams met on a daily basis throughout the breakthrough process while others met weekly or as needed. In addition, Turn Time Team co-leads Durst and Hammack fueled momentum and maintained coordination of the seven breakthrough teams by convening a weekly meeting attended by one union and management representative from each breakthrough team. Each week, Durst and Hammack asked, “Are we in Breakthrough?” The focus of each meeting was to share progress, consider implications for changes across teams, plan actions to address setbacks, and maintain a Breakthrough pace. Every team pair was challenged to keep their teams moving forward in a weekly cycle of rapidly prototyping ideas and concepts. Early on in the process, members of the Flow Team visited Boeing’s 737 manufacturing facility in Seattle, where they studied how 737s are built on a moving assembly line. Shortly thereafter, the group of 170 determined that the best way to achieve their breakthrough goal was to design a “Pulse Line”, a variation of the moving assembly line, where an aircraft would move through 3 work areas on a 12 day schedule. As the Flow Team developed the core workflow for the Pulse Line, the other teams worked on creating processes and procedures to support the new concept. On January 30, 2006 Tulsa launched production on the MD80 Pulse Line. Prior to the Breakthrough Work Design®, it took an average of 24 days (actually 28 calendar days because no work was done on weekends) to perform a heavy check overhaul on an MD-80 and 700 people on 7 docks were needed to maintain the schedule of heavy checks for the MD-80 fleet. Once the Breakthrough Work Design was implemented, the time to overhaul was reduced to about 12 days with the schedule of heavy checks for the entire fleet maintained by 400 people in half the original hangar space, enabling AA to put valuable aircraft back into the schedule in half the time. Collaboration Pays Off Because Tulsa’s management and leaders of TWU Local 514 took the risk to collaborate, they preserved jobs and improved the airline’s competitiveness. Both the unit cost and turn time for the MD80 fleet were cut nearly in half. There was an added benefit of creating new opportunities for American to compete directly with MROs that had once been the possible recipients of work outsourced from ©2014 Overland Resource Group 6 American. The 300+ mechanics, clerks, management and staff, and hangar space made available by the redesign became a new source of revenue for the airline, taking in work from a variety of other airlines. The Pulse Line and the addition of 3rd party work insourced from new customers were significant contributions to the goal set by Tulsa’s leaders to improve the operation by $500M, a goal they achieved at the end of 2006.3 It should be noted that while the MD80 Breakthrough was the most visible significant contribution to AA Tulsa’s performance improvements, there were many other teams formed and initiatives accomplished in support of the base’s $500M goal. Teams across the base discovered and implemented improvements in everything from reducing turn time on engine overhauls to extending the useful life of drill bits. The ultimate achievement of the cost savings and performance improvements in Tulsa was possible because so many people, managers, staff, union, and non-union employees banded together to achieve a common goal. In 2006 AMR posted a profit of $231 million. In 2005 the corporation lost $857 million. As Senior Vice President Bob Reding stated to the Tulsa Base employees on February 7, 2007 at the celebration of the Breakthrough accomplishment, "The successful accomplishment of the very aggressive breakthrough goal of $500 million in value creation in less than two years is proof that the concepts of working together and continuous improvement this company set in motion three years ago can achieve positive results for our employees, shareholders and customers."4 1. Reed, D. (2003, Apr 24). American flight attendants ok new contract concessions. USA Today. Retrieved from http://usatoday30.usatoday.com/money/biztravel/2003-04-24-cartycover_x.htm 2. Banstetter, T. (2007, February 26). American Airlines CEO's Turnaround Plan Worked. Fort Worth Star-Telegram. 3. Stewart, D. R. (2007, March 30). Airline allegiance: Union, company invest in future. Tulsa World. Retrieved from http://www.tulsaworld.com/archives/airline-allegiance-union-companyinvest-in-future-aa-boosts-maintenance/article_e4c95664-8ec6-5ffd-91aa-d87c53e21eea.html 4. Stewart, D.R. (2007, February 2). AA celebrates achievements. Tulsa World. Retrieved from http://www.tulsaworld.com/archives/aa-celebrates-achievements/article_1564b162-74655de6-a4ef-b6115cd43be0.html ©2014 Overland Resource Group 7