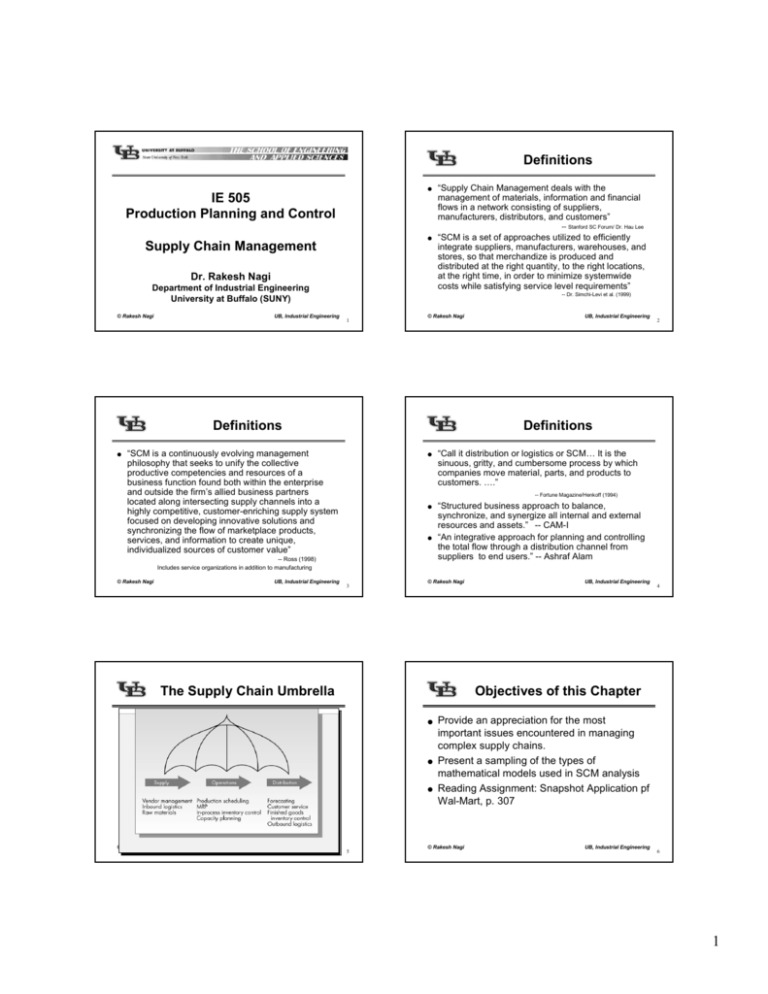

IE 505 Production Planning and Control Supply Chain Management

advertisement

Definitions IE 505 Production Planning and Control ● “Supply Chain Management deals with the management of materials, information and financial flows in a network consisting of suppliers, manufacturers, distributors, and customers” ● “SCM is a set of approaches utilized to efficiently integrate suppliers, manufacturers, warehouses, and stores, so that merchandize is produced and distributed at the right quantity, to the right locations, at the right time, in order to minimize systemwide costs while satisfying service level requirements” -- Stanford SC Forum/ Dr. Hau Lee Supply Chain Management Dr. Rakesh Nagi Department of Industrial Engineering University at Buffalo (SUNY) © Rakesh Nagi UB, Industrial Engineering -- Dr. Simchi-Levi et al. (1999) 1 © Rakesh Nagi Definitions ● ● “Call it distribution or logistics or SCM… It is the sinuous, gritty, and cumbersome process by which companies move material, parts, and products to customers. ….” ● “Structured business approach to balance, synchronize, and synergize all internal and external resources and assets.” -- CAM-I “An integrative approach for planning and controlling the total flow through a distribution channel from suppliers to end users.” -- Ashraf Alam -- Fortune Magazine/Henkoff (1994) ● -- Ross (1998) Includes service organizations in addition to manufacturing UB, Industrial Engineering 3 © Rakesh Nagi The Supply Chain Umbrella ● ● UB, Industrial Engineering UB, Industrial Engineering 4 Objectives of this Chapter ● © Rakesh Nagi 2 Definitions “SCM is a continuously evolving management philosophy that seeks to unify the collective productive competencies and resources of a business function found both within the enterprise and outside the firm’s allied business partners located along intersecting supply channels into a highly competitive, customer-enriching supply system focused on developing innovative solutions and synchronizing the flow of marketplace products, services, and information to create unique, individualized sources of customer value” © Rakesh Nagi UB, Industrial Engineering 5 Provide an appreciation for the most important issues encountered in managing complex supply chains. Present a sampling of the types of mathematical models used in SCM analysis Reading Assignment: Snapshot Application pf Wal-Mart, p. 307 © Rakesh Nagi UB, Industrial Engineering 6 1 Transportation Problem ● ● ● ● ● ● Transportation Problem Special case of Min Cost Flow Problem Shipping and Distribution Applications From plants to warehouses or warehouses to retailers, respectively Let there be m plants with known supplies (Si corresponding to supply point i) And n warehouses with know demands (Dj corresponding to demand point j) Identify flows at min cost to satisfy demand from given supply (cij is unit shipping cost point i) UB, Industrial Engineering © Rakesh Nagi ● Minimize n x ij ij i =1 j =1 ● S.t. n ∑x m ij ≤ Si for i = 1,2, ij ≥ Di for j = 1,2, j =1 m ∑x i =1 xij ≥ 0 7 n for all i, j UB, Industrial Engineering © Rakesh Nagi Transportation Network 8 Transportation Problem ● cij S1 m ∑∑ c D1 For the model to possess a feasible solution, total supply should be at least as large as total demand m n ∑ Si ≥ ∑ D j i =1 j =1 S2 D2 ● S3 Plants © Rakesh Nagi It is convenient to assume equality by adding a dummy destination with remaining supply Warehouses UB, Industrial Engineering 9 © Rakesh Nagi Transportation Problem ● ● ● UB, Industrial Engineering 10 Standard Simplex Simplex solution to an LP problem has at most k positive variables, where k is the number of independent constraints Convince yourself that there are M+n-1 independent constraints in the transportation problem Also note that a key result in network theory is that at least one optimal solution to the TP has integer-valued xij provided Si and Dj are integers. © Rakesh Nagi UB, Industrial Engineering ● ● ● ● 11 Step 1: Select a set of m+n-1 routes that provide an initial basic feasible solution Step 2: Check whether the solution is improved by introducing a non basic variable. If so, go to Step 3; otherwise, Stop. Step 3: Determine which routes leave the basis when the variable that you selected in Step 2 enters. Step 4: Adjust the flows of the other basic routes. Return to Step 2. © Rakesh Nagi UB, Industrial Engineering 12 2 Initial Solution Initial Solution ● Northwest corner rule ● Algorithm: Begin by selecting X11 (that is, start in the northwest corner of the transportation simplex tableau). Thereafter, if Xij was the last basic variable selected, then next select Xi,j+1 (that is, move one column to the right) if source i has any supply remaining. Otherwise, next select Xi+1,j (that is, move one row down). 1 8 ● 3 10 2 6 A 4 9 35/0 9 12 13 10 7 20 14 20 9 50/40/20/0 16 5 10 C Demand ui Supply 35 B Northwest corner rule: Example 45/10/0 20/0 30 40/30/0 30/10/0 UB, Industrial Engineering © Rakesh Nagi 10M 30/0 Initial Solution Minimum Matrix Method ● Algorithm: Find the minimum Cij and assign to Xij the higher of Si or Dj. Reduce the demand and supply (Si- Xij; Dj- Xij). Repeat until done. Note that the last arcs chosen could be very expensive. 1 8 2 6 3 12 13 9 16 Vogel’s Approximation Method ● Algorithm: For each row and column remaining under consideration, calculate its difference, which is defined as the arithmetic difference between the smallest and next-tothe-smallest unit cost Cij still remaining in that row or column. (If two unit costs tie for being the smallest remaining in a row or column, then the difference is 0.) In that row or column having the largest difference, select the variable having the smallest remaining unit cost. (Ties for the largest difference, or for the smallest remaining unit cost, may be broken arbitrarily.) Supply 7 20 50/20/0 5 1 30 40/10/0 10 45/30/0 ● 35/15/0 30 14 C Demand 4 9 20 9 B 3 10 2 15 20/0 30/10/0 30/0 UB, Industrial Engineering © Rakesh Nagi Z=2,460 UB, Industrial Engineering 16 © Rakesh Nagi 15 Initial Solution ● Initial Solution Vogel’s approximation method 1 8 2 6 3 10 ● 4 9 Supply 35 12 13 7 14 9 16 5 2 B 50 C Demand Col Diff 4 30 40/10 45 20 30 30/0 1 3 3 2 1 8 2 6 3 10 4 9 Supply 35 9 12 13 7 14 9 16 5 3 B 50 C Demand Col Diff 5 10 45 1 © Rakesh Nagi 30 40/10/0 20/10 3 30 30/0 3 UB, Industrial Engineering 17 2 6 A 3 10 4 9 13 7 10 9 12 Supply Row Diff 2 35/25 3 B 50 14 C Demand Col Diff 9 16 5 10 45 1 30 40/10/0 20/10/0 30 6 1 8 Row Diff 2 A Vogel’s approximation method 1 8 Row Diff 2 A 9 14 Initial Solution ● A UB, Industrial Engineering © Rakesh Nagi 13 2 6 A 3 10 10 9 12 B C Demand Col Diff 4 9 25 13 16 © Rakesh Nagi 20/10/0 2 50/0 5 10 45/0 1 Row Diff 4 5 9 Supply 35/25/0 7 45 14 30/0 3 30 40/10/0 30/0 30/0 3 UB, Industrial Engineering 18 3 Initial Solution For ABC-> 1234 example ● Northwest corner rule ● Minimum Matrix Method ● Vogel’s Approximation Initial Solution $1,180 $1,080 $1,020 UB, Industrial Engineering © Rakesh Nagi ● Russell's approximation method ● Algorithm: For each source row i remaining under consideration, determine its ui which is the largest unit cost Cij still remaining in that row. For each destination column j remaining under consideration, determine its vj which is the largest unit cost Cij still remaining in that column. For each variable Xij not previously selected in these rows and columns, calculate ∆ij = Cij - ui –vj. Select the variable having the largest (in absolute terms) negative value of ∆ij (Ties may be broken arbitrarily.) ● ● Dual Linear Program is m n Maximize S i vi + ∑ D j w j ∑ i =1 j =1 S.t. v + w ≤ C for all i = 1,2, m i j vi j = 1,2, ij where vi , w j 20 Format for Transportation Simplex Step 2: Optimality Test ● UB, Industrial Engineering © Rakesh Nagi 19 n are unrestrict ed in sign wj ● Theorem of complementary slackness gives: C ij = vi + w j − Cij ≤ 0 if xij = 0 C ij = vi + w j − Cij = 0 if xij > 0 UB, Industrial Engineering © Rakesh Nagi 0 21 Example Example 1 2 2 3 3 11 4 7 1 0 6 1 Supply A 6 B 1 5 8 15 7 5 1 2 A 2 3 2 3 11 4 7 ● 0 6 1 1 5 8 1 7 15 4 5 ● Supply 6 1 B © Rakesh Nagi ● 9 3 Initial Basic Feasible Solution using Vogel’s Approximation = 112 C Demand ● 10 C Demand vi+wj - Cij 6 ● 1 ● 10 ● 9 3 3 2 2 UB, Industrial Engineering 23 Finding vi and wj Set vA = 0 arbitrarily to determine all other duals vA + w2 - 6 = 0; so w2 = 6 vC + w2 - 9 = 0; so vC = 3 vC + w4 - 5 = 0; so w4 = 2 vA + w3 - 10 = 0; so w3 = 0 vC + w1 - 9 = 0; so w1 = 6, etc. © Rakesh Nagi UB, Industrial Engineering 24 4 Example ● Step 3: Identify incoming variable (A2) 1 2 A 2 3 0 1 2 5 1 6 -4 8 -1 1 15 0 0 -5 0 6 3 9 0 5 0 12 1 2 A 1 2 6-z 1 2 3 z 0 B 4 7 5 6 5 8 1+z C Demand 15 1 B 3 3 5 UB, Industrial Engineering © Rakesh Nagi A 2 3 4+z 0 1-z 8 B 5 ● ● 4 7 6 8 A 1 B 1 2 15 2 3 1 1 0 6 10 5 8 6 7 C Demand ● 15 6 A 1 B 10 UB, Industrial Engineering C Demand © Rakesh Nagi 27 A 2 3 0 1 5 0 ● 4 7 3 11 Supply 1 6 B 5 ● 8 7 7 15 6 0 -1 -5 0 6 3 9 0 12 5 0 8 6+z 7 4 7 3 11 z 6 6 1 1 15 0 5 Supply 1 9 2-z 3 2 2 UB, Industrial Engineering 10 28 1 ● MRP logic to manage distribution systems (Martin, 1990). Advantage over ROP systems is that it can deal with changing demand patterns However it ignores uncertainty 9 1 3 5 ● 1 1 C Demand v_I -1 Distribution Resource Planning (DRP) Step 4: Adjust the flows – find new basis (cost = 100) 1 2 15 0 Example ● 26 1 0 -2 3 2 3 5 2 2 1 6 8 1 2 1-z 1 9 2 3 © Rakesh Nagi 3 Identify which variable leaves (A1) Supply 1 0 5 0 6 4 7 3 11 -3 0 2 C w_j 1 0 -5 9 0 12 0 0 5 2 2 4 7 3 11 2 3 -5 9 3 5 B 15 -2 3 0 1 Step 4: Adjust the flows – find new basis (cost = 101) A 0 2 1 3 UB, Industrial Engineering 1 2 6 1 5 v_I -1 Step 3: Identify incoming variable (A3) Supply z 3-z 7 10 Example 3 11 5+z C Demand 6 © Rakesh Nagi Step 3: Identify which variable leaves (B2) 1 2 2-z 1 1 0 0 2 C w_j 25 2 2 4 7 3 11 0 Example ● 9 3 3 0 -2 5 10 6 15 2 3 1 2 2 Supply 1 0 5 0 9 4-z 7 8 5 7 1 2 1 1 1 Step 3: Identify incoming variable (B3) Supply A 4 7 6 1 C Demand 6 3 11 4 0 B ● 3 11 2 3 2 1 Identify which variable leaves (C2) A Step 4: Adjust the flows – find new basis (cost = 104) v_I 1 0 0 2 C w_j ● 4 7 3 11 0 B ● Example 2 2 10 Step 3: Test for optimality again 1 2 A 2 3 -1 1 B 0 -5 5 © Rakesh Nagi 0 6 -2 8 0 1 C w_j 4 7 3 11 0 0 2 -5 0 5 4 1 0 15 -1 3 v_I -2 9 0 11 UB, Industrial Engineering 29 © Rakesh Nagi UB, Industrial Engineering 30 5 Delivery Routes in Supply Chains Practical Issues in Vehicle Scheduling ● Vehicle Scheduling Problems are of two types ¾ ¾ ● 1. 2. 3. UB, Industrial Engineering © Rakesh Nagi 31 Arc-based (e.g., snow removal, garbage collection) Node-based (e.g., collection and distribution) Schrage (1981) list these features: Frequency Requirements (e.g., daily) Time Windows Time dependent travel times Practical Issues in Vehicle Scheduling 4. 5. 6. 7. UB, Industrial Engineering © Rakesh Nagi 32 Designing Products for Supply Chain Efficiency Multidimensional capacity constraints (weight/volume) Vehicle types (different capacities and costs) Split deliveries (more than 1 vehicle to a customer) Uncertainty (e.g., traffic conditions, weather, vehicle breakdowns) ● Historically Product Design has been “throw over the wall” to manufacturing. In recent past we have ● Now – ● ¾ Design For Manufacturing (DFM) ¾ Concurrent Engineering ¾ Design for Logistics (DFL) ¾ Three-dimensional concurrent engineering (3- DCE): Products, Processes, and Supply Chains UB, Industrial Engineering © Rakesh Nagi 33 © Rakesh Nagi Designing Products for Supply Chain Efficiency ● ● ¾ Product design for efficient transportation and shipment ¾ Delayed differentiation (Postponement of final product ● ● configuration) ● Benetton: Dyeing sweaters after knitting (“gray stock”) HP: Localization of printers (correct power supply + plug) can be done at DC rather than factories ● Additional issues ● ¾ The configuration of the supplier base ¾ Outsourcing arrangement (3PL) ¾ Channels of distribution (DCs, 3P wholesalers, licensing, or direct selling) © Rakesh Nagi ● UB, Industrial Engineering 34 Role of Information in SCM How logistics considerations enter design UB, Industrial Engineering 35 The Case of Pasta Barilla (Harvard B School) Barilla is an Italian manufacturer of pasta In late 1980s the head of logistics tried to introduce a new distribution approach JITD The idea was to get the distributor sales #s and Barilla would decide when and how large should the deliveries be. At that time distributors would independently place weekly orders based on std reorder point methods. This would cause large swings in demand for Barilla’s factories due to the “Bullwhip Effect” The change was met with great resistance but adopted © Rakesh Nagi UB, Industrial Engineering 36 6 Role of Information in SCM Bullwhip Effect Role of Information in SCM ● ● ● ● ● The Case of Pasta Barilla (cont.) JITD system was implemented with striking results It was a win-win for Barilla and its distributors This is known as “Vendor Managed Inventory” or VMI today Now, Proctor and Gamble has accepted VMI for Wal-Mart, etc. UB, Industrial Engineering © Rakesh Nagi ● ● ● Industry and academics realized that the orders placed by distributors had much more variance than sales at retail stores. P&G coined the term “bullwhip” effect Where does it come from? ¾ Demand Forecast updating ¾ Order batching at stages causes spiky demands to previous suppliers ¾ Price fluctuations ¾ Shortage gaming 37 UB, Industrial Engineering © Rakesh Nagi Bullwhip Effect: Causes Demand Forecast updating 38 Bullwhip Effect: Causes ● Order Batching ¾ We will see this in MRP systems too, order batching (EOQ-type) translates a smooth demand pattern into spiky demand at “lower” levels ● Price fluctuations ● Shortage gaming ¾ “forward buying” due to attractive prices ¾ When product is in short supply the manufacturer places customers on allocation, so the customers inflate demand to make up for expected shortfall. UB, Industrial Engineering © Rakesh Nagi 39 © Rakesh Nagi Information Sharing ● Channel Alignment 40 Multilevel Distribution Systems Bullwhip Effect: Elimination* ● UB, Industrial Engineering ¾ All parties share POS data (for forecasts also). Fortunately, IT has helped – EDI, for instance. ¾ Reduction of fixed costs (ordering cost via EDI; transportation costs by mixed product and LTL shipments or outsourcing – 3rd party logistics) ● Price Stabilization ● Discouragement of Shortage Gaming ¾ Value-pricing rather than promotional pricing ¾ Allocate based on past sales rather than orders. * Lee, Padmanabhan, and Whang (1997) © Rakesh Nagi UB, Industrial Engineering 41 © Rakesh Nagi UB, Industrial Engineering 42 7 Multilevel Distribution Systems ● Advantages of intermediate storage ● Disadvantages ● Reading Assignment § 6.10 pp. 346-351 on “Designing the SC in a Global Environment” ¾ Risk pooling (aggregate demand has lower variation) ¾ DCs can be designed to meet local needs ¾ Economies of scale in storage and movement ¾ Faster response time ¾ May require more inventory ¾ May increase total order lead times ¾ Could result in higher cost of storage and movement ¾ Could contribute to the bullwhip effect. © Rakesh Nagi UB, Industrial Engineering 43 8