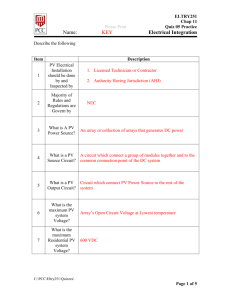

PV and the Electrical Code

advertisement