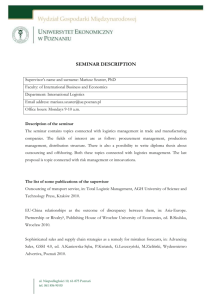

Does the outsourcing of logistics services keep its promise of

advertisement