Hydrogenation of Nitrobenzene to Aniline

advertisement

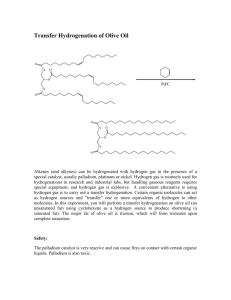

MultiMax Appliaction Note ™ Dr. Fabio Visentin Herbert Briggeler Dr. Olivier Ubrich Hydrogenation of Nitrobenzene to Aniline Mettler-Toledo AG, AutoChem Mettler-Toledo AG, AutoChem Mettler-Toledo AG, AutoChem 1. Introduction Catalytic hydrogenation of aromatic nitro compounds is an industrially important process for the introduction of amino functionality into pharmaceutical and agrochemical intermediates and in the polyurethane chemistry. Aromatic nitro compounds are hydrogenated very easily, and hydrogenations have been carried out under a wide range of conditions including the vapor phase. They are known to be potentially hazardous reactions, especially because the hydroxylamine intermediates formed are often thermally unstable and can disproportionate with a significant temperature increase causing large explosions [1]. During aryl-nitro hydrogenation, formation of the bimolecular azo and azoxy compounds is also possible [2]. These compounds can be hydrogenated to arylamine along with formation of hydrazo compounds. The extent of azo and azoxy formation depends on temperature and accumulation of arylhydroxylamine [3]. 2. Apparatus Technology that reduces the time required for screening, optimization, characterization, and scale-up of target compounds holds significant time-to-market value for chemical and pharmaceutical companies and contract manufacturing services. Automated laboratory reactors (ALR) are essential tools for these purposes. new technology to decrease time to market while increasing their knowledge base of the chemical processes at earlier stages of the development cycle. The information gained directly impacts the areas of process research, organic synthesis, process development, and manufacturing. Pharmaceutical and chemical companies are turning to this Hydrogenation of nitro-compounds was studied at lab scale to understand the process. In order to access the role of mass transfer, experiments with different stirrer speeds were performed. Experiments with different pressure were also done. The goal was to define the necessary rules to run The ALR deliver precise and repeatable control of critical reaction variables (temperature, stirrer No. 03-2007 the hydrogenation experiments in the chemical reaction regime or at least to monitor the influence of the mass transfer with different reaction conditions [4]. To do this, the hydrogen uptake was measured by two methods, the first one using a mass flow meter, the second one by measuring the pressure drop in a small gas reservoir where the hydrogen was stored. The reaction was also studied in term of heat flow monitoring, i.e. by monitoring the difference between the temperature of the reactor contents and the temperature of the jacket (Tr -Tj). speed, etc.) and automation of routine experimental procedures (dosing, pH control, etc.), allowing the rapid optimization of critical reaction variables (catalyst, solvent, pressure, dosing rate, etc.). Thanks to integrated real-time analytics, the reaction behavior can be observed at each moment without taking samples. Experiments can be run on scales from as little as 25 mL during the characterization phase. Hydrogenation of Nitrobenzene to Aniline ™ The MultiMax RB04-50 Reactor Box with Hastelloy® reactors of 25-50 ml as a working volume ™ (part of the MultiMax family) is ™ used here. MultiMax is an automated parallel reactor system, designed for process screening and optimization. It allows increasing the productivity while taking benefit from precise, reproducible and documented experiments. ™ MultiMax is very versatile so that a wide range of experiments can be performed. It features the temperature control of the reaction mixture and jacket simultaneously as well as multiple dosing, magnetic or mechanical stirring, pH, volumetric and gravimetric dosing controls. Each reactor is independent from the other, offering enhanced flexibility. The high quality of the temperature control and measurement allows the user to get valuable information such as reac- tion initiation, reaction end point and relative thermal data. ™ The MultiMax intuitive software interface has been designed for easy experiment definitions, data visualization as well as data export. 3. Hydrogenation of nitrobenzene using a MultiMax™ system To allow reactions under pressure, ™ the MultiMax system is provided with an automatic gas uptake system (A10 and A60) or with a manual gas uptake system (M30, M100 and M200). The automatic gas uptake is provided with a pressure regulator LMPress10 (up to 10 bar) or LMPress60 (up to 60 bar) that allows controlling the pressure in the reactor automatically. The manual pressure regulator instead, allows the user to control the pressure in the reactor manually up to 200 bar. A mass flow meter (optionally) and a reservoir are used to measure the hydrogen consumption (see Figure 1). Moreover, for each pressure vessel the gassing stirrer has been installed to improve the mass transfer effect by pumping the gas into the liquid phase (see Figure 3). To improve the information content of a single measurement of a reaction, reactors are often combined with further analytical sensors such as an IR-ATR probe. METTLER TOLEDO has developed the patented ReactIR reaction monitoring system, which comes in several different configurations including a 6mm diameter probe or a system integrated into the bottom a Hastelloy vessel [5, 6]. The probe fixed on the bottom of the 50 ml vessel is used here in this work. The Hastelloy reactor vessel is also available without the IR-ATR probe. The inserts can be dismantled individually. Stirrer blades with larger dimensions can be used, too. The stirrer has been designed in such a way that even at high liquid levels a significant gas mass transfer is guaranteed. Automatic Gas Uptake Manual Gas Uptake LMPress60 Pressure sensor Pressure regulating valve Reservoir Reactor RB04-50 ReactIR400 Figure 1 MultiMaxIR system with an RB04-50 Reactor B Pressure gauge Needle valve for sampling and discharging Bent 1/4” connections Easy closure Optional with DiComp sensor Powerful stirrer motor Pt100 sensor Rupture disc units - 200 bar - 100 bar - 30 bar 2 mm flexible tubing Additional opening Figure 2 Overview of one reactor with magentic coupling, sensors and IR probe on the bottom of the reactor Kalrez O-ring Tube for dosing Tube for sampling and discharging Tr sensor tube Gassing stirrer Figure 3 Configurable reactor setup Possibility to dismantle dosing and dip tube Hydrogenation of Nitrobenzene to Aniline 4. Experimental procedure NO2 + 3H2 35-60°C MetOH Pd/C 5% 2-4-6 bar Solvent: Methanol, 35 mL Catalyst: Pd/C, 5% Substrate: NH2 Ratio catalyst/substrate: Stirrer speed: + 2H2O The reactor was filled initially with 35 mL of methanol, 0.03 mg of 5 % Pd/C and 3.1 g (0.0252 mol) of nitrobenzene. The desired reaction temperature was set to 50 °C, and as soon as the set temperature was reached, to start the reaction two ways were followed: adding the hydrogen in the reactor at the desired pressure or increasing the stirrer speed up to 1200 rpm. As Figure 5 shows, the software allows monitoring eight signals at the same time in a graph. Here, the most relevant signals are displayed: (Tr - Tj), pressure of the reactor, pressure of the reservoir, temperature of the reservoir and the H2 uptake. 5. Results and discussion 5.1 Hydrogen uptake The reaction was monitored by measuring the consumption of the hydrogen using a Mass Flow Meter (see Figure 6 and 12) and by measuring the pressure drop in the reservoir used to feed hydrogen to the reactor (volume of 150 mL and maximum pressure of 250 bar, see Figure 1 and 7). A comparison is shown in Figure 8. It may be noted that the reaction was carried out at a constant hydrogen pressure. Using the Mass Flow Meter, the software allows the user to moni- tor the instantaneous and the total hydrogen consumption. Using the volumetric method to measure the H2 uptake, the pressure and the temperature in the reservoir have to be monitored as shown in Figure 5. Temperature of the reactor contents: Pressure in the reactor: Nitrobenzene, 3.1 g = 0.025 mol 1.25 g·mol-1 Variable, rpm 50 °C 2.4, 4 and 6.3 bar (H2, const.) Table 1 Recipe for the hydrogenation of nitrobenzene Figure 5 View of the evolution of the monitored signals during the experiment. Figure 7 instead shows the agreement between the heat flow trending and the gas consumption. A comparison between the hydrogen uptake using the Mass Flow Meter and the volumetric method is shown in Figure 8. The two methods give the same result [7]. Figure 6 Totalizer integrated in the MultiMax™ software Figure 7 Monitoring of the pressure in the reservoir and the pressure in the reactor Hydrogenation of Nitrobenzene to Aniline 5.2 Mass transfer effects Influence of the stirrer speed (external diffusion) In order to assess the role of the external mass transfer on the reaction rate, the effect of the stirrer speed was studied. The stirrer speed was varied from 200 to 900 rpm (see Figure 9). The overall effect of an increasing stirrer speed is that the rate of the reaction increases. This trend can be explained by an increase of the H2 absorption in the liquid phase with increasing stirrer speed. By this the mass transfer increases, too. As it can be seen in Figure 9, a significant change in the rate of reaction occurred when the stirrer speed was varied from 200 to 900 rpm. This indicates the presence of the mass transfer limitation for the diffusion of hydrogen from the gas-liquid interface to the bulk liquid and subsequently to the external surface of the catalyst. ™ The MultiMax is a very precise instrument. It allows the user to see small variations in the gas consumption as shown in Figure 9b. In hydrogenation reactions, the knowledge of the influence of the stirrer speed is crucial to understand the mixing regime of the system. In order to optimize the reac- tion conditions (catalyst, catalyst loading, pressure, temperature …), a distinction has to be made between • reactions limited by the mass transfer and • reactions where the rate determining step is assumed to be the surface reaction between the organic substrate and H2. Figure 8 Comparison between the H2 uptake using the Gas Flow Meter and the hydrogen uptake using the reservoir and the concentration profile of the aniline measured by FTIR (see below). Therefore, the stirrer speed plays a fundamental role to distinguish between mass transfer limitation and process optimization. 5.3 Pressure effects The effect of a change in partial pressure of hydrogen on the relative concentration of nitrobenzene was studied in the range of 2.4 to 6.3 bar and shown in Figure 10. When the hydrogen pressure was increased, the rate of reaction increased, too. Figure 10 shows that when the pressure was changed from 2.4 to 6.3 bar, a significant change in the rate of reaction occurred, indicating the possibility to optimize the reaction by adjusting the pressure ™ conditions. The MultiMax shows again very precise measurements: (approximately) the same amount of hydrogen consumed for three different pressures is shown in Figure 10. Figure 9a Effect of the change in the stirrer speed (200 to 900 rpm) on the reaction rate of the hydrogenation of nitrobenzene Figure 9b Zoom of a region between 1400 and 1800 seconds. Reaction conditions: substrate: nitrobenzene (0.025 mol); catalyst: 5% Pd/C (~0.03 g); solvent: methanol (35 ml); pressure: ~6 bar; temperature: 50 °C; ratio catalyst/substrate = 1.25 g • mol-1 Hydrogenation of Nitrobenzene to Aniline 5.4 The heat flow trending of the reaction Preliminary information of the heat flow trending of the reaction is given by the difference between Tr and Tj where Tr is the temperature of the reactor contents and Tj the temperature of the jacket (Tr - Tj). The heat flow trending can be seen as a “rate meter” [8]. It allows the user to have a qualitative overview of the reaction kinetics. To get quantitative information, one needs to perform experiments with a calorimeter with high performances. A reactor with these requirements is the METTLER TOLEDO RC1. The profiles shown in Figure 11 represent the typical profiles of the heat of reaction for hydrogenations of nitro groups. The experiments are the same as described in chapter 5.3 where the hydrogen uptake at different pressures is shown (see Figure 10). The Tr - Tj profile shows, as first result, the start and the end of the reaction and its shape gives an overview of the reaction kinetics. Kinetics is the study of the reaction rates or the study of how fast reactions occur under different conditions. It usually includes a study of the mechanism of reactions, which is a look at how the reacting molecules break apart and then form new molecules. This knowledge allows chemists to control reactions and/or design new or better ways to produce the desired products. The heat flow trending (Tr -Tj) shows that the reaction shows zero order behavior. The reaction rate is therefore independent of the concentration of reactant and accumulation of nitrobenzene is observed. The reaction is therefore not dosing-controlled. Doubling the concentration has no effect on the reaction rate. An interesting result is the comparison between the integration of the hydrogen uptake and the temperature difference Tr –Tj. As shown in Figure 12, the two signals are comparable (overlapping). Due to this comparison, it can be proved again that the instrument has high precision also under pressure and with heterogeneous reactions. Figure 10 Effect of partial pressure of hydrogen (2.4, 4 and 6.3 bar) for the hydrogenation of nitrobenzene. Reaction conditions: substrate: nitrobenzene (0.025 mol); catalyst: 5% Pd/C (~0.03 g); solvent: methanol (35 ml); temperature: 50 °C; ratio catalyst/ substrate = 1.25 g • mol-1. Figure 11 Effect of partial pressure of hydrogen (2.4 to 6.3 bar) on the heat flow signal for the hydrogenation of nitrobenzene. Reaction conditions: substrate: nitrobenzene (0.025 mol); catalyst: 5% Pd/C (~0.03 g); solvent: methanol (35 ml); pressure: 2.4 to 6.3 bar; temperature: 50 °C; ratio catalyst/substrate = 1.25 g • mol-1 Figure 12 Comparison between the measurements done with the Mass Flow Meter (gas flow) and the difference of Tr-Tj (heat flow). Reaction conditions: substrate: nitrobenzene (0.025 mol); catalyst: 5% Pd/C (~0.03 g); solvent: methanol (35 mL); stirrer speed: 900 rpm; pressure: 2.4 to 6.3 bar; temperature: 50 °C; ratio catalyst/substrate = 1.25 g • mol-1. Hydrogenation of Nitrobenzene to Aniline 5.5 IR measurements As mentioned previously and shown in Figure 1, the MultiMax™ system is provided with an FTIR. The spectrophotometer is directly ™ connected in the MultiMax software as shown in Figure 13 ™ (MultiMax IR ). The IR spectra were acquired using the ReactIR4000 Spectrophotometer and the ReactIR software. The spectra were measured using an attenuated total reflectance (ATR) probe coupled to the spectrophotometer. The spectra were measured in the range of 1100 to 1800 cm-1. The peak at 1505 cm-1 corresponds to the C-H bending, the peaks at 1605 cm-1 and 1630 cm-1 correspond to the NH2 bending absorption of aniline, the peak at 1530 cm-1 to the NO2 asymmetric stretch absorption, and the peak at 1350 cm-1 to the NO2 symmetric stretch absorption of nitrobenzene. All these peaks were chosen to follow the reaction (see Figure 14) [4, 7]. The time-dependent profiles of the initial compound and the final product can be estimated using the ConcIR software. This software uses the principle component analysis to extract the relative concentration and the pure spectra (see Figure 8). Figure 13 The MultiMax™ software can communicate with different instruments, including the ReactIR Figure 14 Part of the IR spectrum recorded as a function of time during the hydrogenation of nitrobenzene at 50 °C. The peaks indicated at 1530 and 1350 cm-1 were used to determine the decreasing concentration of nitrobenzene and the peaks indicated at 1505, 1605 and 1630 cm-1 were used to determine the increasing concentration of aniline during the hydrogenation reaction. Hydrogenation of Nitrobenzene to Aniline 6 Conclusions ™ The MultiMax RB04-50 Reactor Box (four reactors of 50 mL each) has been used to investigate the hydrogenation of nitrobenzene. The main advantage of these reactors is the small amount of compounds necessary to investigate the reaction. In addition, the reactors are completely independent of temperature controlling, pressure and stirrer speeds. This enables the user to investigate more than one parameter at the same time and logging all the data. It has been shown that even at the 50 mL scale the hydrogenation can be investigated in details. ™ The MultiMax experiment provides some very good information related to kinetics and mass transfer. 7 References [1] Tong W. R., Seagrave R. L., Wiederhorn R., 3,4-Dichloroaniline autoclave incident. Loss Prevention. 1977, 11, 71-75. [2] Kosak J. R. Hydrogenation of nitroarenes - The hydroxylamine intermediate. Catalysis of Organic Reactions, edited by Rylander P. N., Greenfield H. and Augustine R. L., Marcel Dekker. 1988. [3] Rains R. K., Lambers E. A.; Genetti R. A., Hydrogenation of nitroarenes – the effect of ring substituents on hydroxylamine accumulation. Mettler-Toledo AutoChem Inc. 7075 Samuel Morse Drive Columbia, MD 21046, USA Phone +1-410 910 8500 Fax +1-410 910 8600 E-Mail: autochem.marketing@mt.com Mettler-Toledo AG, AutoChem Sonnenbergstrasse 74 CH-8606 Schwerzenbach, Switzerland Phone +41-44 806 77 11 Fax +41-44 806 72 90 E-Mail: ALR.marketing@mt.com Subject to technical changes. ©05/2007 Mettler-Toledo AG Printed in Switzerland Marketing RC/ALR Three-phase reactions under pressure such as hydrogenations of nitrobenzene have been performed in order to demonstrate the advantage and the quality of the instrument’s measurement ™ with the MultiMax IR RB04-50 system for high pressure combined with a real-time FTIR spectrophotometer. The rate of hydrogenation of nitrobenzene to aniline over a 5% Pd/C catalyst in a three-phase reaction at 50 °C is strongly influenced by the intraparticle mass transfer as well as by the gas-liquid and liquid-solid mass transfer. Therefore, the effects of H2 pressure and stirrer speed on the initial rates were discussed to asses the role of mass transfer. Chemical Industries (Dekker). Catalysis of Organic Reactions. 1996, 68, 43-52. [4]Visentin F., Kinetic Study of Hydrogenation Reactions of Aromatic Nitro Compounds Using a New Pressure Resistant Reaction Calorimeter Combined with a FTIR-ATR Device. Diss. ETH, Zurich, 2005. [5]ReactIRTM iC10, ReactIRTM 4000, MultiMaxIRTM, http://www.mt.com/ AutoChem (Mettler Toledo). [6]Visentin F., Gianoli S. I.; Kut O. M., Hungerbühler K., A Pressure-Resistant Small-Scale Reaction Calorimeter That The hydrogen uptake and the heat flow trending (Tr -Tj) have also been used to characterize the chemical reaction. The heat flow trending (Tr -Tj) shows as a first qualitative result that accumulation of reagent takes place, i.e. the reaction in not dosing-controlled. Moreover, to improve the information content of a single measurement of a reaction, the ™ MultiMax has been combined with an IR-ATR probe per vessel. The absorbance spectra for all the components of the reaction have therefore been acquired and studied. The Hastelloy vessels are easily exchangeable and available with and without the IR-ATR probe. Combines the Principles of Power Compensation and Heat Balance (CRC.v4). Organic Process Research & Development. 2004, 8, 725-737. [7]Visentin F., Puxty G., Kut O. M., Hungerbühler K., Study of the Hydrogenation of Selected Nitro Compounds by Simultaneous Measurements of Calorimetric, FT-IR, and Gas-Uptake Signals. Ind. Eng. Chem. Res. 2006, 45, 4544-4553. [8]Hawkins Joel, Heat Flow Profiling as a Tool for Process Optimization: Tr–Tj as a «Rate Meter» for Every Flask. MT User Forum, Newport. 2002. www.mt.com/MultiMax For more Information Quality certificate. Development, production and testing according to ISO 9001. Environmental man­agement system according to ISO 14001. European conformity. The CE conformity mark provides you with the assurance that our products comply with the EU directives.