Comparative Cost Study of a 35m Wind Turbine Blade using

advertisement

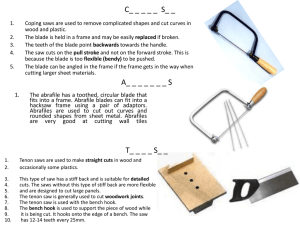

Comparative Cost Study of a 35m Wind Turbine Blade using Infusion and Prepreg Materials Technology Introduction Wind turbine blades are manufactured using advanced composite materials due to their specific properties and their flexibility for component construction. In recent years as blade sizes have increased, and as manufacturing output has accelerated, the choice of materials and the production route has become increasingly critical. Two material technologies have emerged during this rapid growth of the industry to meet the increasing demands on output, performance and quality: Prepreg Technology; and Infusion Technology. These two technologies are well established and account for the majority of blades currently in operation. However, the wind industry continues to develop higher MW output turbines which require larger blades, and as a consequence the demands on the materials and process continue to increase. As a response to the evolving market, the debate on the most appropriate technology for blade manufacture is becoming more intense. The selection of a material technology is a complex issue as it has implications on the whole supply chain. This study uses a simple comparative 35m blade model to highlight the many parameters that need to be considered when making a strategic choice between infusion and prepreg technology for blade manufacturing. 1.1 Composite Processing Technology The majority of blade manufacturers using infusion technology use epoxy resin as their chosen matrix, but polyester is also used in this process. Prepreg technology is currently exclusively epoxy based. A simplistic overview of the fundamentals of the two material technologies is presented in the following sections. 1.1.1 Infusion Technology The general principal of infusion technology is to draw a resin into the reinforcing fibres and fabrics using a vacuum. The vacuum reduces the pressure at one end of the fabric stack allowing atmospheric pressure to force the resin through the stack. The speed and distance that you can infuse a fabric stack will be dependent on the following parameters: The viscosity of the resin system The permeability of the fabric stack The pressure gradient acting on the infused resin η D ΔP The relationship between these can be simply defined using the following equation with respect to the speed of the infusion process v. v ∝ D x ∆P η WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Therefore the speed of an infusion is increased with increasing permeability of the fabric stack (D), increased with increasing pressure gradient (ΔP), and decreased with increasing viscosity (η). Infusion Processing Schematic The requirement for a low viscosity resin for the infusion process is met by using standard liquid polyester or epoxy systems. Once the fabric stack is infused with resin the temperature is raised, typically between 50 to 70 °C, to accelerate and complete the curing process. 1.1.2 Prepreg Technology Prepreg is an abbreviation for “pre impregnation” where a fibre layer or fabric is impregnated with a resin to form a homogenous precursor that is subsequently used to manufacture composite components. The resins used to manufacture prepregs have inherently high viscosities and are therefore solid at room temperature allowing easy handling, cutting, and lay-up into the mould without any transfer or contamination from the resin. Once in the mould prepregs are then cured under vacuum at elevated temperatures, typically between 80 and 120 °C for industrial applications. Prepreg Processing Schematic WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Prepregs are often supplied in roll format and provide the benefits of highly controlled resin content, higher performance resins than with infusion, controlled fibre alignment in unidirectional products (a key benefit for mechanical performance), and fast deposition rates and automation capability. However, as a consequence of the inclusion of higher performance resins, the requirement for chilled storage and shipping, and the additional processing step of “prepregging”, prepregs are more expensive per kg than the equivalent resin and reinforcement in an infusion process. Furthermore, the increased processing temperatures required for prepregs can also increase tooling costs. However, prepregs provide some benefits with respect to process reliability and repeatability, higher levels of automation, higher mechanical performance, and carbon fibre utilization (infusion of carbon fibre is increasingly seen as unviable). 2. Summary of Methodology The blade model was developed to provide a financial analysis of the two manufacturing technologies. Many assumptions have been used in the development of the model and as a consequence the financial output is useful from a qualitative perspective only. However, taking a financial approach to the model enables the clear identification of key parameters and their influence on the cost of a blade. Unfortunately, the model only provides analysis on blade manufacturing and does not consider service life and performance, which will have a significant effect on the life-cycle cost of a blade. The blade model was constructed using the following steps: ¬ Definition of a 35m blade geometry and structural design based on Class I loads and fixed tip deflection ¬ Creation of a Bill of Materials (BOM) for both infusion and prepreg structural design ¬ Determination of the direct labour required for blade manufacture form the detailed manufacturing route for the spar and shell components ¬ Determination of the annual indirect labour and annual plant overheads based on 4 mould sets ¬ Determination of plant CAPEX and annual depreciation ¬ Determination of tooling CAPEX and annual depreciation ¬ Financial analysis of annual plant output: Blade cost, Profit, Asset Turn, Return on Total Assets Each step is described in detail below with assumptions and presentation of the comparative results. 3. Blade Structural Design 3.1 Blade Overview The blade model is based on a 35m blade manufactured using a shell and box spar structural arrangement. The blade has no pre-bend. The structural arrangement for both infusion and prepreg blades is a structural box spar section, i.e. the primary structural member, consisting of two unidirectional spar caps and biaxial sandwich shear webs. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology The root section is integrated into the box spar. The box spar supports two aerodynamic shell fairings joined at the leading and trailing edges of the blade. Blade Construction 3.2 Blade Construction Options The blade structural arrangement described above is used as a common basis to compare the following material options: ¬ E-Glass infused box spar and shells ¬ E-Glass pre-preg box spar and shells 3.3 Loads The comparative study is based on equivalent stiffness which tends to be the typical structural design driver for this size of blade. Flapwise blade stiffness is required in order for the blade tip to clear the tower and for the ratio of first bending natural frequency to rotor frequency to be sufficiently high to avoid resonance. In this case, a target flapwise tip deflection, towards the tower, has been chosen to be met by both design options. Furthermore, this target deflection has been adjusted to ensure that all blade designs meet or exceed the required minimum ultimate strength criteria. As a result of this adjustment the blade stiffness is significantly higher than would be required for an optimised blade design. The fatigue strength has not been considered for the stiffness based comparative study. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Minimum strength criteria relate to four ultimate load cases where aerodynamic loads have been calculated to represent extreme gusts and wind shifts causing flapwise bending, towards and away from the tower, as well as edgewise bending, with and against rotation directions. Buckling stability has been restricted to spot checks. An aeroelastic model has been used to calculate the corresponding section shear forces, bending moments and torques. Ultimate design loads have been obtained by factoring these up by the required Germanischer Lloyd (GL) general load factor of 1.5. Note that no aeroelastic iteration has been performed to assess the effects of final stiffness and inertia distributions on the above aerodynamic loads. 3.4 Design Allowables The value of the allowable stress/strain is known as the design strength of the material, Rd. This is calculated by dividing the material characteristic value, Rk, by the partial safety factor, γMx: Rd = Rk /γMx (Equation 1) The characteristic value, Rk, is determined from a statistical equation that quantifies the reliability of the test data. Therefore, the greater the variation in the test results (large standard deviation and variation coefficient) the lower the characteristic value. If the test results are very reproducible, giving a low standard deviation and variation coefficient, the characteristic value will be very close to the mean test result. The characteristic value is calculated according to the process documented in Germanischer Lloyd (GL) Rules and Regulations as follows: (Equation 2) where x is the mean of the test values, v is the variation coefficient, and n is the number of tests. The characteristic value will also decrease as the number of tests decreases. However, this change is small compared to the effect of the variation coefficient. The partial safety factor, γMx, is calculated separately for the general static strength/stiffness analysis and the fatigue analysis. The partial safety factor is obtained using Equation 3: (Equation 3) where for both static and fatigue analysis a general safety factor of γM0 = 1.35 is used. The partial safety factors generated by GL are as follows where N is the number of fatigue cycles (10,000,000): WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Factor General Strength Fatigue General Safety Factor 1.35 1.35 Ageing – C1 1.35 N1/10/N1/14 (E-Glass or Carbon) Temperature – C2 1.1 1.1 Manufacture – C3 1.1 1.0/1.1 (U/D or stitched) Post-cure – C4 1.0 1.0 Total Material Safety Factor 2.21 7.44/8.18 GL Partial Safety Factors Therefore, from Equation 1, the maximum design allowable strength that can arise in a blade laminate during operation is calculated. Due to the different material properties within a composite structure the design is performed using strain values as these will in general be consistent throughout the anisotropic composite structure. The allowable strain values have been calculated using the characteristic strength values divided by the average modulus and subsequently by the material partial safety factors. Some typical values are illustrated in the table below. Material Test Char. Strength (MPa) Modulus GL Partial Safety Factor Design Allowable Prepreg UD 1600g Tensile Strength 952 42.0 2.21 1.02% Prepreg UD 1600g Compressive strength 687 42.0 2.21 -0.74% Infusion UTE 800g Tensile Strength 821 37.8 2.21 0.98% Infusion UTE 800g Compressive strength 511 37.8 2.21 -0.61% Prepreg UD 1600g Fatigue (10e7) 952 42.0 7.44 0.30% Infusion UTE 800g Fatigue (10e7) 821 37.8 8.18 0.26% Material Design Allowables The values in the above table show that the prepreg design allowables are higher than those for the infusion process and in particular for compression loading. This is a consequence of the higher performance resin in prepregs preventing fibres from buckling, and due to the high fibre alignment in collimated unidirectional prepreg. The infusion process uses slightly lower performance resins due to the requirement of low viscosity and stitched unidirectional fabrics which introduce a level of fibre waviness. The net result is the designer can utilize the higher design allowables for prepreg and reduce the material content in the blade. 3.5 Blade Design Program (“BDP”) The BDP is effectively a very detailed cantilevered beam model set up to perform the analysis of a blade box structural spar and supported blade shell. Slender beam theory assumptions are applicable to the BDP model (no shear deformation of cross sections). Polynomial curve fitting functions are used to provide a convenient analytical representation of the blade geometry. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology The blade model is divided into a large number of sections with intermediate subsections (typical section spacing 0.2m) created by linear interpolation between input sections (typ. spacing 1m). Each blade section is divided into 12 elements. These elements are grouped into a number of laminate zones as shown in Figure 4. Blade Section and Elements Each zone along the blade has a laminate input and laminate properties are computed based on classical laminate theory. Bending stiffnesses EIxx, EIyy and EIxy are then calculated by summing up contributions from each element around the section. A similar calculation is carried out for the shear centre and torsional stiffness properties (GJ) of each section. The centre of gravity (CG) position and detailed mass distribution are also calculated. This information is used to calculate the required outputs for each load case in turn: ¬ Deflection curves ¬ Strain chordwise and spanwise distributions ¬ First bending natural frequency (Rayleigh’s quotient) ¬ Mass estimate ¬ Bill of materials (BOM) 3.6 Results The design outputs for the blade are summarised in the following table. It should be noted that no load iteration steps were made following the determination of the mass and stiffness distributions. The reduction of the mass of the prepreg blade would reduce the static and dynamic loads on the blade and therefore design iterations would enable further optimisation of the laminate. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Blade Design Parameter Infusion Prepreg Tip Deflection (m) 2.53 2.53 Lead-Lag Deflection (m) 0.21 0.27 Flapwise Frequency (Hz) 1.142 1.359 Blade Mass (kg) 6,186 4,987 4.87 x106 3.79 x106 Rotational Inertia (kgm ) 2 Blade Design Output 4. Bill of Materials (BOM) The output from the blade design program provides the net material requirement but does not take into consideration the level of waste or over consumption associated with each manufacturing process, and this needs factoring in to the BOM. The assumptions used in the model to determine the gross material requirements are as follows: ¬ 5% additional consumption for Dry Fabrics and Prepreg. A consequence of kitting and nesting inefficiencies ¬10% additional consumption for Infusion Matrix. A consequence of additional resin consumption in the core and the infusion delivery system ¬ 8% waste for Core Kitting. A consequence of kitting and nesting inefficiencies ¬20% additional consumption for Adhesive. A consequence of the difference between theoretical and production bond line adhesive requirements The BOM output from the blade design program is summarised in the table below. Material Component Infusion BOM Prepreg BOM Biax 600gsm (XE600) 960 m 588 m2 Triax 900gsm (YE900) 485 m 522 m2 Uni-directional (EGL1600) 1,451 m2 1,247 m2 Fleece surface veil 140 m - Core (PVC/SAN 80kg) 3.38 m3 3.38 m3 Structural adhesive 263 kg 263 kg Gelcoat 70 kg 70 kg 2 2 2 Bill of Materials (composites) In addition to the BOM for composite materials some assumptions have been made as to the costs of other significant items in a blade. For vacuum consumables a separate estimate has been provided for both infusion and prepreg blades. These assumptions are summarised in the following table. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Item BOM Cost (€) Root Studs 1,800 Lightening Protection 1,500 Painting 3,000 Vacuum Consumables € 1,000/€ 500 Bill of Materials (additional items) The composites BOM from the blade design output was then converted, using the additional consumption factors and current market volume pricing (April 2009), to produce the total composite cost for each model. The additional items were then added to both models to give the final BOM cost for the blades. The results are summarised in the table below. Material Option BOM Cost (€) Infusion Technology 26,849 Prepreg Technology 30,312 Bill of Materials Cost (composites) 5. Direct Costs The direct manufacturing costs are estimated from analysis of each processing step in the construction of the spar and shell components. For simplicity the manufacture of the root section and the attachment of the root studs are included in the spar manufacturing process. As there are many different solutions to the root section of a blade, a general estimate of time and resource is provided for both the infusion and prepreg blade models. The labour required for each processing step is estimated together with the total elapsed tool time for each step. The summary of labour and time required for shell and spar component manufacture are summarised in the tables overleaf. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology Process Infusion Prepreg hrs labour hrs labour Mould Preparation 0.5 4 0.5 4 Gelcoat Application 0.5 12 0.5 12 Gelcoat Part-cure 0.5 1 0.5 1 Tissue Application 0.5 12 Fabric/Prepreg Lay-up 5 12 4 12 Vacuum Bag Application 1 4 0.5 4 Infusion 2.5 12 Cure 5 1 5 1 Consumable Removal 0.5 6 0.5 6 Adhesive Application 1 6 1 6 Adhesive Cure 5 1 5 1 Demould 1 6 1 6 Total Mould Time 23 18.5 Labour and Time for Shell Manufacture Process Infusion Prepreg hrs labour hrs labour Mould Preparation 0.5 4 0.5 4 Fabric/Prepreg Lay-up 4 6 3.5 6 Root Studs 5 2 5 2 Vacuum Bag Application 0.5 4 0.5 4 Infusion 1.5 6 Cure 5 1 5 1 Consumable Removal 0.5 4 0.5 4 Demould 1 4 1 4 Total Mould Time 18 16 Labour and Time for Spar Manufacture In addition to the direct labour costs for component manufacture an estimate of the labour for pre-kitting the fabric and prepreg prior to lay-up was also calculated. It was assumed for the purposes of this model that the time and labour costs for pre-kitting prepreg and dry fabric are identical. This gives an additional direct labour cost of €360 based on 2 people kitting an entire blade in 6 hours. The total direct labour costs for blade manufacture were then calculated using a standard labour rate of €30/hr. The total mould time for shell manufacture was also WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 10 calculated as this is required to determine the output capability of the blade plant for each composite technology route. The annual plant output is used to allocate indirect costs and depreciation costs of infrastructure and tooling CAPEX, to each blade. The total direct costs are summarised below. Direct Labour (€) Infusion Blade Prepreg Blade 6,105 4,245 Total Direct Costs 6. Indirect Costs The indirect costs were determined by consideration of a manufacturing plant with floor space for 4 blade production lines and the associated indirect labour of running a plant. Annual blade production output was then used to allocate annual indirect costs to each blade. 6.1 Indirect Labour The annual indirect labour cost was calculated using the headcount assumptions in the table below: Position No Plant Manager 1 Maintenance Manager 1 Warehouse 1 Process Engineer 2 Quality Engineer 3 Electrical technician 1 Maintenance technician 1 Security 1 Production Manager 1 Planning and Logistics 1 Finance 1 Total €770,000 Indirect Labour 6.2 Utility Costs The utility costs include gas, electricity, rates, and telephone taken from a European manufacturing plant with similar energy demands. It is assumed that because of the higher curing temperatures of prepreg materials that the infusion process energy consumption was 65% of the prepreg process consumption. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 11 Utility Costs (€/annum) Infusion Blade Prepreg Blade 549,500 695,500 Utility Costs The total annual indirect costs are summarised below. These costs are allocated to the blade as detailed in Section 8. Indirect Cost (€/annum) Infusion Blade Prepreg Blade 1,319,900 1,465,500 Total Annual Indirect Costs 7. CAPEX The CAPEX has been divided into manufacturing plant infrastructure, and tooling and associated manufacturing equipment. 7.1 Blade Plant Infrastructure The CAPEX requirements for a manufacturing plant with 4 blade production line were estimated using a nominal cost of 550 €/sqm for land and buildings. The estimates for the required floor space are summarised in the table below. Floor Space sqm Warehouse and Administration 1,000 Spars 4,000 Shells 6,000 Finishing 4,000 Total 15,000 Manufacturing Plant Dimensions Mechanical and Electrical (M&E) CAPEX was estimated at 66% and 40% of the plant land and buildings cost for prepreg and infusion technology respectively. The higher M&E costs were assumed for prepreg technology due to the requirement for higher control of environmental temperature for storage and use of prepreg materials, and an increased level of automation. The total blade plant infrastructure CAPEX was depreciated over 20 years. CAPEX requirements are summarised below. Total Plant CAPEX (€) Infusion Blade Prepreg Blade 12,150,000 14,350,000 Plant CAPEX WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 12 7.2 Tooling CAPEX The tooling cost analysis is based on the standard master model approach where CNC machined plugs are produced to enable the fabrication of female shell and spar moulds. The two common approaches to design and manufacturing of blades are: Non structural shells with the structural box spar (used in this study); and, Structural shells with integrated spar cap and shear web connectors. The structural box spar design has some benefits in the manufacturing process and also allows integration of the root section. However, the consequence of having a female mould for the box spar increases the tooling costs compared to the shear web approach. In this study for simplicity the female moulded box spar manufacturing route has been adopted for both the infusion and prepreg blade design. The estimates in the following table for tooling CAPEX are based on the assumption that there is a 50% premium for prepreg tooling due to the higher temperature performance required. Item No Item cost (€) Total (€) Shell Mould Set 4 650,000 2,600,000 Shell Plug 1 400,000 400,000 Spar Mould Set 4 300,000 1,200,000 Spar Plug 1 225.000 225,000 Kitting Machine 2 150,000 300,000 1,725,000 4,725,000 Prepreg Total Infusion Shell Mould Set 4 433,290 1,733,160 Shell Plug 1 400,000 400,000 Spar Mould Set 4 199,980 799,920 Spar Plug 1 225,000 225,000 Kitting Machine 2 150,000 300,000 1,408,270 3,458,080 Total Tooling CAPEX The CAPEX was then depreciated over 5 years for tooling and plugs, and 10 years for the kitting equipment to produce the annual depreciation rates in the table overleaf. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 13 Item Depreciation (€/annum) Prepreg Shell Mould Set 520,000 Shell Plug 80,000 Spar Mould Set 240,000 Spar Plug 45.000 Kitting Machine 30,000 Total 915,000 Infusion Shell Mould Set 346,600 Shell Plug 80,000 Spar Mould Set 160,000 Spar Plug 45.000 Kitting Machine 30,000 Total 661,616 Annual Depreciation Costs 8. Allocation of Indirect and Depreciation Costs The allocation of the annual indirect costs and the annual depreciation of the tooling were based on the productivity of the blade factory. The productivity was calculated from the shell mould cycle (the rate determining step for blade production), an operating schedule of 49 weeks a year at 24/7, and at an efficiency of shell mould utilisation of 85%. The productivity data is summarised below: Position Infusion Prepreg Shell Mould Cycle Time (hrs) 23.0 18.5 Operational Days/Annum 340 340 Operational efficiency 85% 85% Number of Moulds 4 4 Theoretical Blades/Annum 1,206 1,500 Blade Productivity The annual indirect costs and depreciation were then allocated to each blade as illustrated in the table overleaf. The higher productivity of the prepreg blade plant reduces the allocation of indirect cost and depreciation to the individual blade cost. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 14 Infusion Blade Prepreg Blade Indirect Cost (€/blade) 1,094 977 Plant Deprecation (€/blade) 504 478 Tooling Deprecation (€/blade) 548 610 Total Allocation 2,146 2,065 Blade Cost Allocation 9. Financial Results and Ratios The calculation of the cost of manufacturing a blade has been obtained by the analysis of a theoretical blade design and manufacturing model. The structural engineering study has allowed the calculation of the BOM for both infusion and prepreg manufacturing technology. A review of the manufacturing process, capital equipment and the manufacturing facility has then enabled calculation of the direct and indirect cost elements associated with blade manufacture. A summary of the costs in provided in the table below: Infusion Blade Prepreg Blade BOM Cost (€) 26,849 30,312 Direct Labour Costs (€) 6,105 4,245 Indirect Labour Costs (€) 1,094 977 Depreciation (€) 1,052 1,089 Total Blade Cost (€) 35,101 36,623 Blade Cost Summary The calculation of the individual blade cost does not give the complete financial picture on the differences between the two manufacturing routes. Due to the difference in productivity of the two blade plants there will be an impact on the annual financial performance and this is best demonstrated using a simple P&L financial analysis and some common financial ratios. The main assumption in this analysis is that the sales price for both blades in the market is the same at €40,000. The P&L analysis is summarised in the table overleaf. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 15 Infusion Blade Prepreg Blade Gross Sales (€) 48,240,000 60,000,000 Material Costs (€) 32,380,180 45,467,912 Direct Costs (€) 7,362,630 6,367,500 Indirect Costs (€) 1,319,900 1,465,500 Depreciation (€) 1,269,116 1,632,500 EBIT (€) 5,908,174 5,066,588 EBIT % 12.2% 8.4% Total CAPEX (€) 12,150,000 14,350,000 Asset Turn 3.97 4.18 ROTA (EBIT x AT) 49% 35% Blade Plant P&L Due to the higher productivity of the prepreg process of 1,500 blades per annum compared to 1,206 for infusion, the allocation per blade of fixed indirect costs and the recovery of depreciation are reduced. This offsets the higher material cost for prepreg material and the associated additional depreciation from the more capital intensive requirements of using prepreg materials. However, as the majority of the contribution to blade cost is related to the materials the 35m infusion blade has a lower overall cost base than that of the prepreg blade. There are some additional cost items that are not included in this model that are difficult to quantify. Repair costs have not been included but it is expected that the reliability of the prepreg process will reduce rework expenditure compared to the infusion process. The benefit of the weight saving of a prepreg blade is even more difficult to quantify as it affects the service life of other components of the turbine. However, this weight benefit can only be realised if the whole turbine system is optimised for light weight blades with a fully integrated design approach. Model validation The indications are that the current market price for a 35m infused blade is approximately $US 50,000. Using a 2009 year to date exchange rate of 1.30 for €/$, the blade market price would be €38,500. This is 10% above the cost estimation for the infused blade in the model and therefore shows a good correlation. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 16 10. Summary A 35m blade design model was created to analyse the costs of blade manufacture using two material manufacturing technologies, resin infusion and prepreg. The summary of the analysis is as follows: ¬ The model validation shows very good correlation with current market pricing of 35m blades. ¬ The higher mechanical properties of the prepreg materials, and in particular the compression strength of the unidirectional glass, enable the design of a lighter blade with less material content than the infusion equivalent. ¬ The BOM costs for the prepreg blade are higher than those for the infused blade due to the inherent additional costs associated with the prepreg manufacturing process and the advanced resin systems used in prepregs. ¬ The Capital Expenditure for the prepreg process is higher than that of infusion due to the higher temperature requirements of the tooling and the additional temperature control requirements for the storage and use of prepreg materials. ¬ The prepreg blade manufacturing is more suited to automated processes and allows increased productivity due to shorter manufacturing cycle times. These productivity benefits partially offset the premium of prepreg material costs. ¬ The resultant financial analysis indicates that for a 35m blade design the infusion process is marginally more profitable than a prepreg blade, although a prepreg facility has a 24% productivity advantage. The analysis has highlighted the main contributing factors of the manufactured cost of a 35m wind turbine blade. What the analysis has not quantified is the effect of manufacturing process on process reliability and repair frequency, and the in-service performance and reliability of the blades. These lifetime service costs could become a significant contributor to the overall cost and should be considered as a critical factor when evaluating choices of manufacturing technology. The current analysis was based on a 35m blade design as this was representative of the mainstream blade size for 1.5MW WTG’s and therefore providing a good baseline study. As blade lengths extend beyond 40m the design choices will become more critical as weight and strength become limiting factors. Therefore, the selection criteria for materials technology will move away from material cost towards performance for the critical components of the blade structure. This will be realised by using higher performance materials like prepreg and ultimately the switch from glass unidirectional fibre to carbon fibre. WE Handbook- 6- Blade Cost Analysis: Prepreg vs Infusion Material Technology 17