Handmade Scraper - The Missouri Folklore Society

advertisement

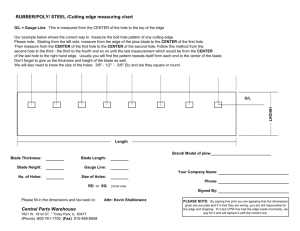

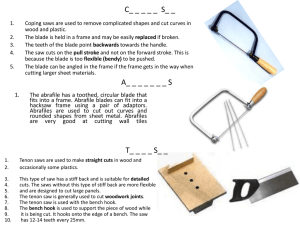

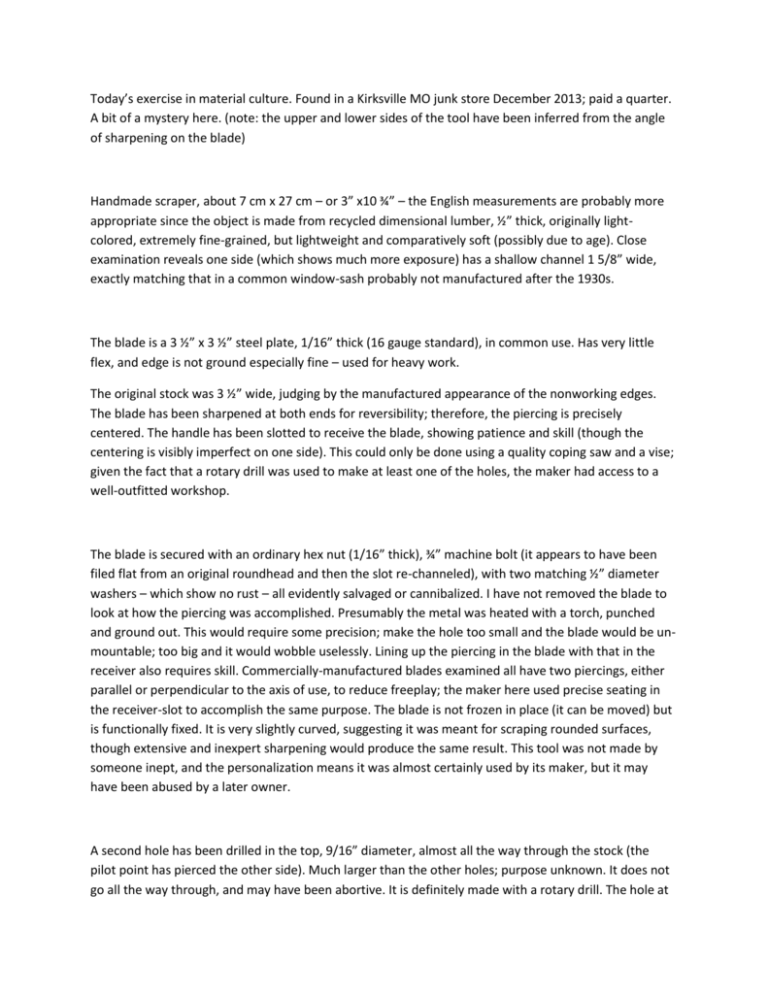

Today’s exercise in material culture. Found in a Kirksville MO junk store December 2013; paid a quarter. A bit of a mystery here. (note: the upper and lower sides of the tool have been inferred from the angle of sharpening on the blade) Handmade scraper, about 7 cm x 27 cm – or 3” x10 ¾” – the English measurements are probably more appropriate since the object is made from recycled dimensional lumber, ½” thick, originally lightcolored, extremely fine-grained, but lightweight and comparatively soft (possibly due to age). Close examination reveals one side (which shows much more exposure) has a shallow channel 1 5/8” wide, exactly matching that in a common window-sash probably not manufactured after the 1930s. The blade is a 3 ½” x 3 ½” steel plate, 1/16” thick (16 gauge standard), in common use. Has very little flex, and edge is not ground especially fine – used for heavy work. The original stock was 3 ½” wide, judging by the manufactured appearance of the nonworking edges. The blade has been sharpened at both ends for reversibility; therefore, the piercing is precisely centered. The handle has been slotted to receive the blade, showing patience and skill (though the centering is visibly imperfect on one side). This could only be done using a quality coping saw and a vise; given the fact that a rotary drill was used to make at least one of the holes, the maker had access to a well-outfitted workshop. The blade is secured with an ordinary hex nut (1/16” thick), ¾” machine bolt (it appears to have been filed flat from an original roundhead and then the slot re-channeled), with two matching ½” diameter washers – which show no rust – all evidently salvaged or cannibalized. I have not removed the blade to look at how the piercing was accomplished. Presumably the metal was heated with a torch, punched and ground out. This would require some precision; make the hole too small and the blade would be unmountable; too big and it would wobble uselessly. Lining up the piercing in the blade with that in the receiver also requires skill. Commercially-manufactured blades examined all have two piercings, either parallel or perpendicular to the axis of use, to reduce freeplay; the maker here used precise seating in the receiver-slot to accomplish the same purpose. The blade is not frozen in place (it can be moved) but is functionally fixed. It is very slightly curved, suggesting it was meant for scraping rounded surfaces, though extensive and inexpert sharpening would produce the same result. This tool was not made by someone inept, and the personalization means it was almost certainly used by its maker, but it may have been abused by a later owner. A second hole has been drilled in the top, 9/16” diameter, almost all the way through the stock (the pilot point has pierced the other side). Much larger than the other holes; purpose unknown. It does not go all the way through, and may have been abortive. It is definitely made with a rotary drill. The hole at the end opposite from the blade (7/16” dia), obviously meant for hanging the tool, appears to have been carved at least partially with a knife. The haft has been beveled at the front, apparently to reduce interference with the surface being scraped. That would not explain the beveling on the upper side of the receiver, unless it shows a taste for symmetry (which is not visible elsewhere) Noted: the beveling is not made easier by applying it to both sides, but it is a trivial effort, and maybe makes the tool reversible. From a practical standpoint, it is hard to imagine the beveling being done before the slotting. The butt end of the handle has been rounded very roughly, but also shows polish from wear, consistent with applying pressure with the heel of the hand. There is no ornamentation; appearance seems to have played very little role in design. Not weighed; estimate less than eight ounces. The most interesting feature here is the complex, unique, ergonomic carving of the handle, entirely asymmetrical. Astonishing effort went into making a tool that even a hundred years ago could be bought cheaply anywhere. It is skillfully whittled, probably with a small knife. It fits comfortably into the left hand of an adult male of average size, with full reversibility – not so the right. Contact-soiling and wear patterns support this hypothesis. This probably explains the artifact – a southpaw, knowing he was going to spend a lot of time pushing this thing, wanted something that would fit *him.*