Degree of Hydration and Strength Development of Low

advertisement

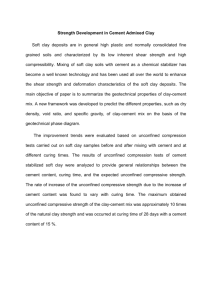

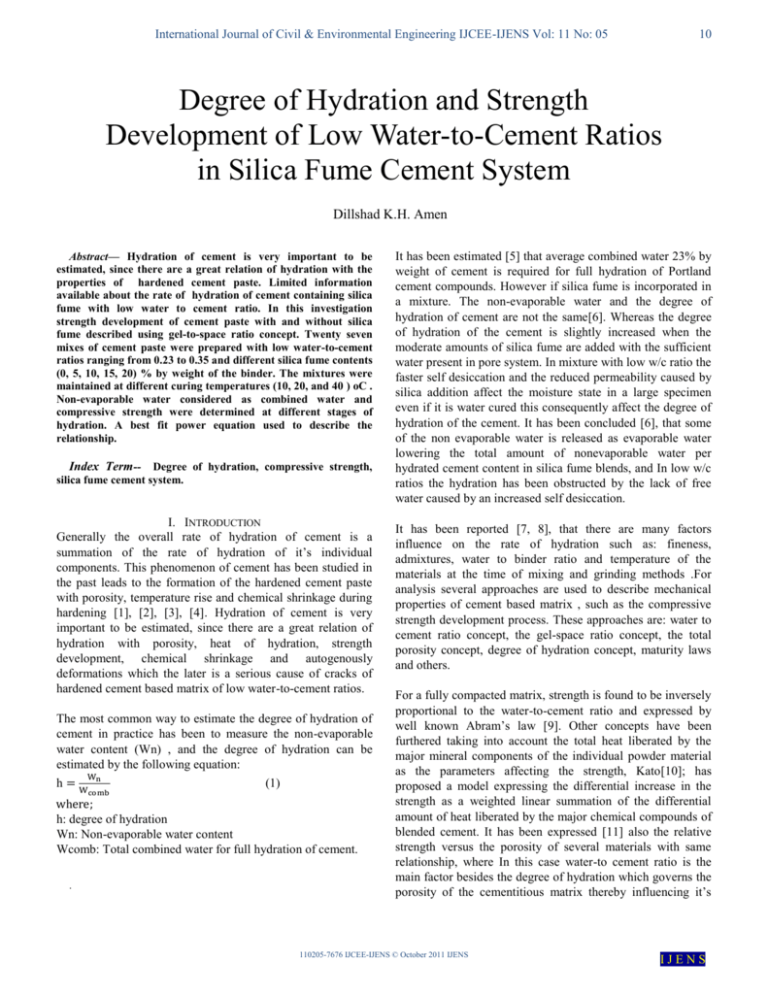

International Journal of Civil & Environmental Engineering IJCEE-IJENS Vol: 11 No: 05 10 Degree of Hydration and Strength Development of Low Water-to-Cement Ratios in Silica Fume Cement System Dillshad K.H. Amen Abstract— Hydration of cement is very important to be estimated, since there are a great relation of hydration with the properties of hardened cement paste. Limited information available about the rate of hydration of cement containing silica fume with low water to cement ratio. In this investigation strength development of cement paste with and without silica fume described using gel-to-space ratio concept. Twenty seven mixes of cement paste were prepared with low water-to-cement ratios ranging from 0.23 to 0.35 and different silica fume contents (0, 5, 10, 15, 20) % by weight of the binder. The mixtures were maintained at different curing temperatures (10, 20, and 40 ) oC . Non-evaporable water considered as combined water and compressive strength were determined at different stages of hydration. A best fit power equation used to describe the relationship. Index Term-- Degree of hydration, compressive strength, silica fume cement system. I. INTRODUCTION Generally the overall rate of hydration of cement is a summation of the rate of hydration of it’s individual components. This phenomenon of cement has been studied in the past leads to the formation of the hardened cement paste with porosity, temperature rise and chemical shrinkage during hardening [1], [2], [3], [4]. Hydration of cement is very important to be estimated, since there are a great relation of hydration with porosity, heat of hydration, strength development, chemical shrinkage and autogenously deformations which the later is a serious cause of cracks of hardened cement based matrix of low water-to-cement ratios. The most common way to estimate the degree of hydration of cement in practice has been to measure the non-evaporable water content (Wn) , and the degree of hydration can be estimated by the following equation: h (1) h h: degree of hydration Wn: Non-evaporable water content Wcomb: Total combined water for full hydration of cement. . It has been estimated [5] that average combined water 23% by weight of cement is required for full hydration of Portland cement compounds. However if silica fume is incorporated in a mixture. The non-evaporable water and the degree of hydration of cement are not the same[6]. Whereas the degree of hydration of the cement is slightly increased when the moderate amounts of silica fume are added with the sufficient water present in pore system. In mixture with low w/c ratio the faster self desiccation and the reduced permeability caused by silica addition affect the moisture state in a large specimen even if it is water cured this consequently affect the degree of hydration of the cement. It has been concluded [6], that some of the non evaporable water is released as evaporable water lowering the total amount of nonevaporable water per hydrated cement content in silica fume blends, and In low w/c ratios the hydration has been obstructed by the lack of free water caused by an increased self desiccation. It has been reported [7, 8], that there are many factors influence on the rate of hydration such as: fineness, admixtures, water to binder ratio and temperature of the materials at the time of mixing and grinding methods .For analysis several approaches are used to describe mechanical properties of cement based matrix , such as the compressive strength development process. These approaches are: water to cement ratio concept, the gel-space ratio concept, the total porosity concept, degree of hydration concept, maturity laws and others. For a fully compacted matrix, strength is found to be inversely proportional to the water-to-cement ratio and expressed by well known Abram’s law [9]. Other concepts have been furthered taking into account the total heat liberated by the major mineral components of the individual powder material as the parameters affecting the strength, Kato[10]; has proposed a model expressing the differential increase in the strength as a weighted linear summation of the differential amount of heat liberated by the major chemical compounds of blended cement. It has been expressed [11] also the relative strength versus the porosity of several materials with same relationship, where In this case water-to cement ratio is the main factor besides the degree of hydration which governs the porosity of the cementitious matrix thereby influencing it’s 110205-7676 IJCEE-IJENS © October 2011 IJENS IJENS International Journal of Civil & Environmental Engineering IJCEE-IJENS Vol: 11 No: 05 strength. Very limited information in the literature available dealt with the rate of hydration in silica fume cement system, whereas the rate of chemical reaction between silica fume and calcium hydroxide produced from the hydration of cement is not well understood. It has been reported [12] that pozzolanic materials have a retarding effect on the hydration of Portland cement especially at early stages of hydration, this reduction in the rate of reaction caused by the shortage of calcium hydroxide which is necessary for the reaction at any stage of hydration. While at later ages when there are sufficient amount of calcium hydroxide produced, rate of reaction will be preceded with further amount of gel produced leading to increase the strength of the matrix. Therefore the degree of hydration, of silica fume cement system at early age is not well known. In this investigation nonevaporable water which is considered as combined water were determined experimentally for cement paste with and without silica fume, then gel-to-space ratio determined based on the total combined water considered as equal to 0.23 that required for full hydration of 1 gm pure cement, while for full hydration of silica fume cement system total combined water calculated based on the amount of water required for chemical reaction of silica fume to be transformed to Silicic acid, and the percentage ratios of the materials (cement + Silica fume) making the composite. The results of gel-space ratio correlated with the strength of cement paste at different stages of hydration using a best fit power or exponential equation. In addition the effect of w/c ratio and curing temperature on the nonevaporable water were taken into account. II. EXPERIMENTAL WORK MATERIALS: Cement: normal type cement from Japan used in this investigation, some of chemical and physical properties of the cement are shown in table (1), Silica Fume: Fine powder silica fume with average size of 0.15 um, and specific gravity 2.2 used as a supplementary cementitious material. Some properties of silica fume are shown in table (2). III. PREPARATION OF THE MIXES Table (3) shows the proportion and preparation of 27 mixtures of the binding material. Mixing time were done about 4+ 1 minutes for all , then the mixes were placed into the molds of prisms (40X40x160) mm according to the ASTM C349-82 for measuring compressive strength from the failed flexural prisms. The prisms were covered by a polyethylene sheets and stored in a controlled room under the temperature of 20 +1 and relative humidity about 80 % for one day , then taken out from the molds , cured in a water bath until the testing date. 11 IV. COMPRESSIVE STRENGTH Modified cube method is used to determine compressive strength after testing modulus of rupture and taking the failed prisms of about 40 mm Cubes. Dimensions of the prepared cubic specimens measured using digital vernier caliper with accuracy of 0.01mm. Compressive strength determined at 12 hours, 1, 3, 7, and 28 days. V. NON-EVAPORABLE WATER After placing the specimens in a controlled room, and after the initial setting of cement, small pieces of the paste fractured from the prisms, sealed and stored in a Lab. At different conditions for different intervals of times [ 2.5 , 6, 12, 24, 48, 72, hours and 7 days] for measuring the combined water (nonevaporable water). The weight of the wet pieces was measured at the end of the specified intervals of time by a digital electronic balance with an accuracy of + 0.01. Specimens were immersed in ethanol for about 7 days. Then, taken out and dried in an oven at 105 oC for about 48 hrs. Dried specimens were weighed and crushed; parts of the crushed material in a ceramic cup were weighed, before placing in a furnace for firing with a constant rate of increase 250o C /hr. up to 1000 oC. Specimens were maintained at this temperature for 2 hours. After heating specimens in a ceramic cup were cooled naturally inside the furnace. Weight of specimens was measured after firing, the difference in the weight is the non evaporable water . Loss on ignition of dry cement and silica fume were determined, the average of 5 specimens was 2.47 % for cement and 3.01 % for silica fume. This subtracted from the determined non-evaporable water, VI. RESULTS AND DISCUSSION COMPRESSIVE STRENGTH Results of compressive strength of hardened cementitious composite at different ages are shown in Table (4-a &4-b), It can be observed that compressive strength of the paste increased with a high rate initially and slows down with increase in curing time for all kinds of the specimens with and without silica fume, this indicated that the hydration of cement is continuous with a high rate initially and slows down with age for different w/c ratios and silica fume contents. increasing w/c from 0.23 to 0.26 showed an increase in compressive strength for some specimens at ages of 3 and 7 days , while beyond 0.26 compressive strength has decreased, this was attributed to stiff mix of 0.23, which decreased the permeability and availability of mixing water for the hydration of cement or might insufficient compaction during the preparation of the mixes. Very stiff mixtures were resulted when cement partially replaced by silica fume. To enhance the flowability of the mixtures containing silica fume; superplasticizer 2% was added, The inclusion of silica fume as a partial replacement of 110205-7676 IJCEE-IJENS © October 2011 IJENS IJENS International Journal of Civil & Environmental Engineering IJCEE-IJENS Vol: 11 No: 05 cement decreased the compressive strength at early ages and have been increased later, with increase level of silica fume in the mixes, this was reported by Atlassi(6), who concluded that for very dense systems with low w/c ratios the hydration may be obstructed by the lack of free water, caused by an increased self desiccation, also because silica fume react with Ca(OH)2 generated from the hydration of cement therefore they have a diluting effect on PC during the period of Ca(OH)2 accumulation causes the effect of silica fume in favor of the system strength to arise. Greatest increase in strength can be seen in the mixture with silica fume at 15%, beyond this limit compressive strength slightly decreased. This indicated that 15 % is the best content of silica fume for the tested cement. It can be observed that (5, 10, and 20 ) % silica fume mixtures have a lower compressive strength than mixtures without. VII. NON-EVAPORABLE WATER Non-evaporable water of the cementitious composite determined for all the mixes at different stages of hydration as shown in Fig. (4). It is shown that the rate of hydration is high at the initial stage and has lowered with time. Degree of hydration can be determined by measuring the ratio of combined water at any stage divided by the total combined water for full hydration of cement which is considered as 0.23 for OPC. Higher rate of hydration were observed relatively for mixtures of lower w/c ratios at early age up to 48 hours curing, that exposed to temperature 20o C , and no significant difference in the hydration rate observed for all the mixtures exposed to curing temperature 10o C and 40o C; beyond this time of curing non evaporable (Combined) water increased with increase of w/c ratio. This indicated the availability of sufficient amount of mixing water and the presence of more space available for the precipitation and growth of hydration products , this increased the hydration rate and decreased the compressive strength, due to the increase in total porosity. Slower rate and higher rate of hydration were observed for specimens cured in low temperature 10o C and high temperature 40o C respectively as shown in Fig.(1) . For sealed specimens if there is no loss of water by evaporation, then adding the ratio of combined water to the moisture content (evaporable water) at any time before curing of cement, the result approximately was the total amount of water or w/c ratio , except some mixtures showed a slight difference ranged from 0.01 to 0.03. At early age up to 7 days, the results showed an increase in the nonevaporable water content per 1 gm binder of silica fume cement systems when silica fume has increased from (015%); beyond this limit for mixture of 20 % silica fume which is cured at 20 oC a slight decrease in the nonevaporable water is resulted. This case followed the same trend of compressive strength development. 12 VIII. STRENGTH DEVELOPMENT In this investigation, gel-to-space ratio concept was used to describe strength development of hardened cement paste with and without silica fume. It is assumed that 1 ml of cement on hydration will produce 2.132 ml of gel , then gel to space ratio determined by the equation: Gel / Space = h h (2) Where: G is the specific gravity of cement ; Gs is the specific gravity of silica fume (2.2); h is the degree of hydration, it is considered equal to the ratio of non-evaporable water-to-total combined water required for full hydration. It is represents about (5 23 percent of the mass of dry cement, while for silica fume cement system total combined water is slightly different which depends on the chemical reaction between silica fume and Ca(OH)2 resulted from the hydration of cement, at different stages, it is determined based on the molecular weights of the elements in a pozzolanic chemical reaction between calcium hydroxide (Ca(OH)2) and silicic acid , this reaction can be schematically represented as follows H4SiO4 (Silicic acid) 100 gm + 30 gm 130 gm Ca (OH) 2 + H4SiO4 CaH2SiO4 · 2 H2O (Calcium silicate hydrate). These reactions indicates that 1 gm of silica fume requires 0.3 ml of combined water for full transformation to Silicic acid , which is consequently transforms to calcium silicate hydrate (gel) , if sufficient amount of Ca(OH)2 is provided by the hydration of cement compounds. Using equation (2), specific gravity of cement is 3.16 , silica fume 2.2 and the percentage of air entrapped in the paste due to insufficient compaction approximately assumed equal to 2%. Gel to space ratio determined at different stages of hydration. Power equation of the type used as a best fit equation to estimate actual compressive strength of the paste as a function of the gel to space ratio. The results is plotted as shown in figure (2 ) &(3) . Based on this equation it is possible to calculate the effect of increasing the water –cement ratio at a given degree of hydration on both the porosity and strength of low water –cement ratio with and without silica fume. IX. CONCLUSIONS Based on the results obtained from the investigation the following conclusions can be drawn: 1) After the age of 48 hrs. higher water-to-cement ratio , resulted to higher rate of non-evaporable (combined) water while for too early age before 48 hrs. Converse effect of water-to-cement ratio were 110205-7676 IJCEE-IJENS © October 2011 IJENS IJENS International Journal of Civil & Environmental Engineering IJCEE-IJENS Vol: 11 No: 05 TABLE I PROPERTIES OF TYPE ( I )CEMENT resulted especially for curing temperature 20o C , and for other temperatures , the differences was very slight. 2) Different contents of silica fume resulted a slight increase in nonevaporable water with the reduction of compressive strength in silica fume cement mixes especially at early age 3) The best silica fume content was 15 % by weight of the composite, whence resulted highest compressive strength at ages of 7 and 28 days. 4) Silica fume cement mixes were influenced by the change in curing temperature more than mixes of pure cement paste. 5) The development of compressive strength of cement with and without silica fume were expressed as a function of the gel-to-space ratio using a power equation, higher correlation coefficient were resulted for cement paste mixes. For further work on this area it is recommended to determine and relate the effect of the degree of hydration especially at early age , on both chemical and autogeneous deformations, which the latter is a serious cause for crack at early age of low water to binder ratios in cement based matrix. REFERENCES Justnes, H., Sellevold, E.J., et, al “ The influence of cement characteristics on chemical shrinkage”, Proceddings of the international workshop on autogeneous shrinkage of concrete , Hiroshima, Japan, June 13 -14, 1998, pp. 67-76. [2] Justnes, H., Van Gemert, A., et al “ Total and external chemical shrinkage of low w/c ratio cement paste” , Advances in cement research , Vol. 8, No. 31, 1996 , pp. 121-126. [3] Justnes, H., Hammer, T.A., et al “ Chemical shrinkage of cement paste mortar and concrete”, Proceedings of the international workshop on autogeneous shrinkage of concrete, Hiroshima , Japan, June 13-14 , 1998, pp. 201-211. [4] Justnes, H. Sellevold, E. J., et al “ Chemical shrinkage of cementitious paste with mineral additives”, Proceedings of the second international research seminar on self-desiccation and its important in concrete technology, Lund, Sweden, June 18, 1999, pp.73-84. [5] Neville A. M., “ Properties of concrete”4th and final edition , Wiley, 4 sub edition 25 July 1996. [6] Atlasi,. E. H , “ Nonevaporable water and degree of cement hydration in silica fume-cement system”, ACI SP 153-37, volume 153, June, 1995. [7] Binici, H. , Cagatay, I. H. , Tokyay, M., Kose, M.M. “ The early heat of hydration of blended cements incorporating GGBFS and ground basaltic pumice (GBP). International Journal of physical sciences , Vol.1 (3) , November, 2006 , pp. 112 – 120. [8] SH Kosmatka, WC Panarese, “ Design and control of concrete mixtures, Portland Cement Association (PCA), Illinois , 1994. [9] Shetty, M.S. “ Concrete Technology Theory and Practice” S Chand and Company Ltd. Ram Nagar, New Delhi, Revised Edition, 2005 [10] Kato, Y. and Kishi, T., “ Strength development model for concrete in early ages based on hydration of constituent minerals” Proceedings of the JCI , 1994 , Vol. 16 , No. 1, pp. 503 -508. [11] Bentz ,D. P. and Stutzman , P. E. “ Curing, Hydration and microstructure of cement paste” , ACI materials Journal , Vol. 103, No.5, September-October 2006. [12] Maekawa, K. , Chaube, R. and Kishi, T. “ Modelling of Concrete Performance – Hydration, Microstructure Formation and Mass Transport, Published by E && FN an imprint of Routledge, London, 1999. 13 Properties Specific Gravity g / cm3 Setting Time Initial (h-min) Final (h-min) Compressive strength 3d N/mm2 7d 28 d Heat of hydration J/gm 7d 28d Secondary oxides % MgO SO3 Loss on Ignition Alkalies Cl 3.16 2-21 3-28 30 45.7 62.3 328 376 1.23 2.12 2.08 0.51 0.015 TABLE II SOME PHYSICAL PROPERTIES AND OXIDES CONTENT OF SILICA FUME Oxides L.O.I H2O C PH Na2O MgO Al2O3 K2O CaO Fe2O3 % 3.0 1.0 --2.5 3.0 1.5 3.0 2.0 3.0 Physical properties Bulk density Specific gravity Surface Area Average Size values 200-350 kg/m3 2.2 200,000 cm2/gm 0.15 um Table III proportions of cement paste mixes [1] Mixes w/c A 0.23 0.23 0.23 0.26 0.26 0.26 0.29 0.29 0.29 0.32 0.32 0.32 0.35 0.35 0.35 B C D E % silica fume 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Temp. 0C 20 10 40 20 10 40 20 10 40 20 10 40 20 10 40 mixes w/c D-5 0.32 0.32 0.32 0.32 0.32 0.32 0.32 0.32 0.32 0.32 0.32 0.32 D-10 D-15 D-20 % silica fume 5 5 5 10 10 10 15 15 15 20 20 20 TABLE IV-A COMPRESSIVE STRENGTH OF HARDENED CEMENT PASTE AT DIFFERENT AGES Age (days) 0.5 1 3 7 28 110205-7676 IJCEE-IJENS © October 2011 IJENS Compressive Strength (N/mm2) for the Mixes A B C D E 15.87 14.25 8.1 5.8 4.33 27.72 24.59 18.29 16.99 17.44 40.46 42.14 42.17 34.47 22.35 50.59 61.1 45.77 48.84 45.65 102.11 89.19 99.03 88.11 82.29 IJENS Tem p. 0C 20 10 40 20 10 40 20 10 40 20 10 40 International Journal of Civil & Environmental Engineering IJCEE-IJENS Vol: 11 No: 05 14 TABLE IV-B COMPRESSIVE STRENGTH OF SILICA FUMES CEMENT SYSTEM AT DIFFERENT AGES. Age (days) Compressive Strength (N/mm2) for the Mixes D-5 D-10 D-15 D-20 0.5 4.45 5.31 4.81 7.94 1 8.45 12.21 16.23 15.37 3 35.32 24.35 36.18 34.2 7 40 42.79 47.87 41.22 28 70.88 69.5 93.99 66.56 0.8 0.7 T=20 0C 0.7 0.6 0.6 0.5 0.5 0.4 0.4 A B C D 0.3 0.2 0.1 0.0 D-5 D-10 D-15 D-20 0.3 0.2 0.1 0.0 0 50 100 150 200 0 0.7 0.7 0 T=10 C 0.6 50 100 150 200 T=100 0.6 0.5 0.5 Degree of hydration T=20 0C 0.4 A 0.3 B 0.2 0.1 0.4 D-5 D-10 D-15 D-20 0.3 0.2 0.1 0.0 0.0 0 50 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 100 150 200 T=400 C A B C D 0 50 100 150 200 0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 50 100 150 200 T=400 C D-5 D-10 D-15 D-20 0 50 100 150 200 Curing time (hours) Fig. 1-a. Degree of hydration of cement paste versus curing time at different temperatures Fig. 1-b. degree of hydration in silica fume cement system at different temperatures 110205-7676 IJCEE-IJENS © October 2011 IJENS IJENS International Journal of Civil & Environmental Engineering IJCEE-IJENS Vol: 11 No: 05 120 15 y = 80.551x4.2644 R² = 0.8411 100 80 60 40 20 0 0 0.2 0.4 0.6 0.8 1 Fig. 2. Relationship between compressive strength and gel-to-space ratio for cement paste 100 y = 129.89x3.5017 R² = 0.7391 80 60 40 20 0 0.00 0.20 0.40 0.60 0.80 1.00 Fig. 3. Relationship between compressive strength and gel-to-space ratio for silica fume cement system D. K.H. Amen, is with the College of Engineering, University of Salahaddin - Erbil-Iraq, dillshadbzeni@yahoo.com . 110205-7676 IJCEE-IJENS © October 2011 IJENS IJENS