Lab Capability - Nanolab

advertisement

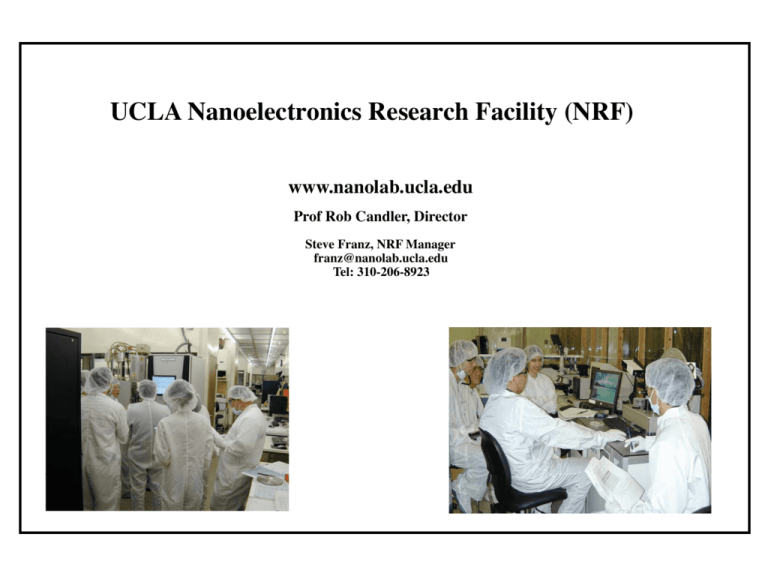

UCLA Nanoelectronics Research Facility (NRF) www.nanolab.ucla.edu Prof Rob Candler, Director Steve Franz, NRF Manager franz@nanolab.ucla.edu Tel: 310-206-8923 The NRF is a recharge center within HSSEAS under the auspices of the UCLA Electrical Engineering Department. UCLA NRF CHARTER NRF MEMBER PROFILE • Establish an interdisciplinary Center of Excellence for nanoscale fabrication among UCLA researchers, other universities and industry • ~ 75 Faculty Users • Graduate UCLA students with relevant fabrication experience useful to industry and further advanced research • >250 Student users (primarily graduate researchers) • Share a common-use facility to reduce research costs and foster intergroup cooperation • Provide a professionally-managed facility which keeps current with process trends and equipment advances • Support UCLA’s education and community service mission • 9 Departments including Bioengineering, Physics Chemistry, EE, MAE, Material Science etc. • Users from >20 Universities such as Cal Tech, UC Riverside, UC Irvine and USC • >45 industry users • NRF supports 2 undergraduate fabrication courses (MEMs and MOS processing classes) • Undergraduates from its “NanoScholars” program NRF OPERATIONS • Lab online for over 20 years • 7 Full Time Professional Engineers with over 100 years experience and a full-time business analyst • Hourly Lab Use Fee to cover general operating cost (see Lab Manager for rate sheet) • Additional hourly charge for use of more costly equipment eg vacuum deposition equipment, SEM, furnaces, ICP etchers etc. • Online written procedures, calendar, reservation system, training lists, email, lab access etc. managed via custom software (LabRunner) • Superusers and staff training system with 2 step certification for complex equipment and training coordinator • Lab available 7 days/week, 16 hours/day • CNID-funded ($3M) equipment upgrades completed in ‘07 • Lab supports CNSI, FENA, DARPA NSF, WIN among others NRF STATISTICS • Annual revenue (2012): $1.8 M • Equipment assets: $ 10 M • Capital Expenditures/ Lab upgrades (2011-12) $ 931K • External income (2012): 39% of total • Lab Usage (2012): 1990 hrs./mo. 145 users/mo. • Student helpers supported: 10 Hrs/month FY 95 FY 96 FY 97 FY 98 FY 99 FY 00 FY 01 FY 02 FY 03 FY 04 FY 05 FY 06 FY 07 FY 08 FY 09 FY 10 FY 11 FY 12 # Users/month #Users/Mo Hrs/mo NRF FACILITY • ~8000 sq. ft. class 1000 + 500 sq. ft. class 100 vertical flow clean room • Vibration-isolated floor, independently suspended from building • Yellow room lithography area for processing photosensitive materials • High purity de-ionized water system (18MΩ-cm) on tap at each hood • 7 facilitized hoods for safe wet chemical processing • High purity (5 9 s) bulk nitrogen gas delivery system • In-situ real time toxic gas monitoring system with remote toxic gas bunker and state-of-the-art safety features UCLA Nanoelectronics Research Facility EST 1992 UNDERGRADUATE TEACHING LAB UNDERGRADUATE TEACHING LAB HYBRID LAB UNDERGRADUATE TEACHING LAB HYBRID LAB FURNACE CHASE Oxidation Badge Entrance MEASUREMENT Unaxis SLR 770 DRIE STS AOE Etcher LT Storage Hi Temp Ox/Annl III-V/METAL Dry Etch Matrix Stripper Porous Si Etch PARYLENE COATER Chem CVC SPUTTER Bonder LT Spin Coat Develop R/D Chem Wet Etch VEECO AFM SOPRA ELLIPS WYCO NANOSPEC Dektaks Chem Logitech CDP CMP Prefurnace Clean LT R/D III-V RTA Ulvac Etcher Filmtek 2000 S 4 Pt Probe Fast Si DRIE HW FE FE LAB OFFICE 14-131 Plating Hood F Si RTA W E T P R O C E S S Wet Si Etch Nanospec Unaxis 790 PECVD STS PECVD ES Chem ES CHA Evap DENTON SPUTTER CHA Evap LT P ES Oxford RIE TEGAL Chem Chem Suss Aligners Chem Inspect NIL 6 ES F Technics RIE F Bake HW M E T A L D E P FURNACE PROCESSING ICP Deposition P M E T A L D E P ALD Storage P XeF2 ETCH HF ACID HOOD Fridge Bake Sloan Ebeam Evaporator S FE Fridge L I T H O G R A P H Y Storage CP Dryer MASK WRITER P Burn Box GOWNING ROOM ResMap 4 pt probe Staging Inspection SEM LT P Flexus Prober SEM SPUTTER LPCVD Oxidation Lab Main Entrance 18-132 Servers Chem Chem Chem Chem Chem Lab Director: Lab Manager: Engineers: Admin Analyst IT & Programming Prof Rob Candler Steve Franz Noah Bodzin, Huynh Do, Max Ho, Tom Lee, Wilson Lin, Hoc Ngo, Joe Zendejas Jamie Kahng Mohammad Shahangian www.nanolab.ucla.edu 8000 sq ft Class 1000 & 500 sq ft Class 100 clean space 18 Megohm DI water 99.999% pure gaseous nitrogen 7 fully facilitized fume hoods 5 ICP deep etchers Si, III-V, metals and oxides 3 Electron Beam Deposition and 2 sputtering systems ~2000 sq ft dedicated yellow room 2 4 stack LPCVD/Oxide furnaces with doping 3 PECVD systems for oxide, nitride & silicon deposition 1 ICP PECVD system for low temperature oxide & nitride Pieces to 4 inch wafer processing with 6 inch capability 2 Suss MA6 top and bottom aligners & 1 Obducat Imprinter Hitachi S4700 Field Emission SEM with EDAX attachment FEI Nova 600 Dual Beam FIB (located in Rm 1129, EV Bldg) SUPPORTS: >250 grad students ~ 75 faculty 9 Departments >40 companies OTHER FACTS: Annual Budget~ $2M $10M equipment Main funding: • Recharge REV 01/10/11 LEGEND LT Lab Log-in Terminal PM5 Lapper Chem HSSEAS recharge center is open to UCLA faculty, other University faculty and industry and is under the auspices of the Electrical Engineering Dept STAGING AREA & CHEMICAL STORAGE Chem Chem Emergency Exit Emergency Evacuation Button Chem ES F HW P S FE ES LAB VITALS Chemical Storage Emergency Shower First Aid Hazardous Waste Phone Spill Kit Fire Extinguisher ELEVATORS NRF IMAGING AT THE NANO-SCALE Hitachi S4700 SEM with EDX probe Features: • Field Emission SEM. • KEV from 0.5 up to 30 KEV. • EDX elemental analysis. ---------> • 1 nm spec resolution. • Load-locked for quick pump down • Low current mode for reduced sample charging Metal stack EDX Spectrum Nova 600 SEM / FIB A state-of-the-art scanning electron microscope, focused ion beam and nanofabrication tool. • • • • • • • • • • • 1.1 nm SEM Resolution 10 nm FIB Resolution Pt., W, and C Deposition 5-axis Stage with 150 mm Travel Wafer Handling Up To 6” TEM Sample Preparation Cross-Sectional Imaging Nanoscale Patterning Basic Circuit Edits Material Deposition High Resolution SEM Imaging Located in Rm 1129, EV NRF THERMAL PROCESSING CAPABILITIES • 2 Modular Process Rapid Thermal Annealers with pyro or TC control –––> • Temperatures to 1200°C • Ramp rates to 200 °C/sec • 2- 4 tube furnace banks: • Dry & wet (steam) oxidation • Phos. doped, undoped & low stress polysilicon, • Standard & low stress silicon nitride • Low Temp Oxide (Phos. doped & undoped) • Sintering/Annealing with forming gas or N2 • High temperature oxidation/anneal to 1300 °C NRF METAL EVAPORATION CAPABILITIES • 2 CHA Mark 40, e-beam evaporators • • • • Cryo-pumped, with 22, 4” wafer capacity and rotating lift-off dome, substrate heat and 6 crucible pockets Thermal deposition, and carousel planetary capability Inficon rate control with Xtal thickness monitor. Multiple films of up to 6 different materials can be deposited sequentially in a single pump down • Sloan 1800-electron-beam evaporator with • • • Substrate heat, and cryo-pumped chamber Closed loop deposition control 4 crucible pockets • Evaporated films include: • Ti, Al, Au, Pt., Ni, Cr, Pd, Al2O3, SiO2, Ta, NiFe, Cu, Au-Ge and Zn • Thicknesses 5 nm to 1 μm NRF METAL SPUTTER CAPABILITIES • Denton Discovery 4 target sputter system • • • • • • 2 RF and 2 DC targets (dielectrics as well as metals) 3 inch quick-change targets for economy and flexibility High temperature heater for in-situ anneal Reactive sputter capability for metal oxide or nitride formation and stoichiometry control Co-sputter capability for unique alloy formation Substrate table capable of multiple size and shapes • CVC 601 3 target sputter deposition with RF etch capability • High throughput, 10, 4 inch wafers/run Denton Films Include: ITO, SiO2, Al, Cu, Cr, Ti, Ni, Nb, SnO2, W, Ru Al2O3, In2O3, Hf, TiO2, Zr, ZrO2 Denton Discovery Sputterer CVC 601 Sputter Deposition System NRF DRY ETCH CAPABILITIES • 3 ICP Silicon/Metal / III-V Deep Etchers: • PlasmaTherm DSE2 fast silicon etcher • • • • • Si Etch rates to >8 μm/min Selectivities to 100:1 Etch depth>200 μm with aspect ratio >20:1 Profile control >85° slope Proprietary notch reduction (undercut)@ dielectric interface • SLR 770 Bosch Si etcher using SF6 and C4F8 • SLR 770 Metal and III-V etcher using Cl2, BCl3 and CH4 • Si test structures etched with DSE2 NRF DRY ETCH CAPABILITIES • 2 ICP Dielectric Etchers: • Ulvac NLD 570 Oxide Etcher • Etch rate to 0.3μm/min and depth to 100μm • Load-locked and turbo-pumped with heated chamber for etch repeatability • Reduced heating for better process control using B field • Uses Ar and C3F8 for straight sidewalls • Etch substrates include glass, quartz, silicon nitride Ulvac Oxide Etcher STS Advanced Oxide Etcher • Etch rate to 1 μm/min and STS AOE ICP Oxide Etcher depths to 50 μm • 2 RIE Etchers: Oxford 80+ and Technics RIE 800 using F chemistry for Si oxide and nitride etching • 2 Tegal barrel strippers and 1 Matrix 105 low damage asher Ulvac-etched glass Microfluidic Channel • Student loads Tegal stripper NRF PLASMA DEPOSITION CAPABILITIES • 3 Low Temperature PECVD Dielectric Deposition Tools for depositing oxides and nitrides of Si: • STS Multiplex PECVD Deposition load-locked system • Stress control (eg SixNy < 5 MPa for low stress and > 1.3GPa for high stress) • Refractive index control (eg 1.9-2.2 for nitride) • Phos doping from 0-4 wt% • Films of oxide, nitride, oxynitride and -Si • Deposition rate control from 10-500 Å/min STS Multiplex PECVD • Deposition temperature from 200-400 °C • Thicknesses from 100 Å to 10 μm with high conformality • PlasmaTherm 790 manual load system • Pieces to 4 inch wafers • Oxide, nitride and oxynitride films Unaxis 790 PECVD system NRF PLASMA DEPOSITION CAPABILITIES • BMR ICP Low Temperature PECVD Deposition Substrates: pieces to 6 inch High density films at < 50°C High conformality, films of oxide, nitride & oxynitride can now be deposited on polymers Low H2 concentration for device stability σ on 6 in. wafer Good thickness uniformity < 2.5%, 3σ • • • • • Wet Etch Rate (A/min) * Nitride Etchant 6:1 NH4F:HF PECVD @ 200oC 1000 800 PECVD @ 300oC 600 400 PECVD @ 400oC 200 0 0 50 100 150 Chuck Temperature 200 NRF Lapping and Polishing Capability Logitech CDP Polisher/de-planarizer • Programmable polisher • Can use alkaline or acid slurries • Sub 100 nm removal uniformity • Ra in the sub-nanometer range • Control of a wide range of process parameters including: plate temperature, carrier speed and force, plate rotation, slurry dispense rate • In-situ pad conditioner • Pieces up to 8 inch substrates Logitech PM5 Lapper • Used to thin dielectric, semiconductor and metal substrates • Samples can be thinned to tens of microns with one micron accuracy • Semiautomatic operation insures uniform flatness with minimal scratching NRF LITHOGRAPHY CAPABILITIES Optical Lithography Lithography 2 Suss MA 6 aligners • Top and bottom side alignment alignment • Bond alignment • Resolution to 0.8 microns microns Lithography Support Equipment • • Programmable spin coaters, bake ovens and programmable hot plates, solvent & acid wet benches Suss SB6 Bonder with anodic and thermocomp- ression bond capability and substrate heating to 450°C Nano-imprint Lithography Lithography Obducat NIL 6 6 • Substrates: pieces to 6 inch, hard or soft soft • Thermal cure with PMMA, MR I 7010 etc. etc. microns • Alignment to about 3 microns °C • Temperature to 300 °C bars • Pressure 15 to 80 bars • Resolution < 50 nm possible possible • Up to 160 step recipes for precise process control control Photomask Fabrication at the NRF Heidelberg DWL 66 LaserWriter Loading a mask plate Inspecting the mask plate Resolution Test Pattern Low-cost, quick turn around mask writing system Supports common CAD programs L-Edit, LinkCAD, AutoCad Patterns 4 -7 inch, Cr/glass substrates Effective write grid: 40 nm Minimal structure size: 1 μm Active write area: 140 mm x 140 mm Positional resolution: 10 nm Exposure Wavelength: 442 nm Supports gray-scale lithography Data Conversion Formats: CIF, GDSII, Gerber, DXF Integrated metrology and alignment system for multi-layer exposures and metrology measurements System can scale and invert polarity of pattern file and can combine files from different layout Exchangeable write heads for resolution/print area trade-off Plates wet-developed and wet-etched using standard NRF wet benches and chemical processes Over 2500 photomasks made to date ATOMIC LAYER DEPOSITION Ultratech/Cambridge Nanotech - Savannah 100 •Materials: Al2O3, HfO2, AlxHfyO • Substrate: Pieces to 4 inch • High conformality • Highly scalable process • High aspect ratio structure (50:1) • Excellent uniformity across the wafer; < 1% • Deposition Temperature: 25 to 250° • Monolayer film thickness control -6 1.6x10 As-Deposited Annealed HfO2~ 110 A -6 1.4x10 0 10 -6 1.2x10 As-Deposited Annealed -1 10 -2 10 -6 1.0x10 -3 TEM Image of As-deposited HfO2 Al2O3 n~1.7 HfO2 n ~ 1.9 AlxHfyOz n ~ 1.6 0 20 40 60 80 100 120 # of cycles 140 160 180 200 2 Jg(A/cm ) 10 2 RMS=1.2 RMS S=1.2 Å Å C(F/cm ) Thickness(nm) AFM Image of As-deposited HfO2 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 -7 8.0x10 -7 6.0x10 -4 10 -5 10 -6 10 -7 10 -7 4.0x10 3.2 nm nm 2.1 nm nm 220 -8 10 -2 HfOxx -1 0 1 2 Vg(V) -7 2.0x10 Si 0.0 -2 -1 0 Vg(V) 1 2 Plasma Atomic Layer Deposition Ultratech/Cambridge Nanotech – Fiji F200 •Substrate: Pieces to 8 inch (4 inch is the standard size) • Load-lock with motorized transfer arm • High conformality and highly scalable process • Excellent uniformity across the wafer; < 1.5% • Ultra high aspect ratio structure (up to 450:1) • Deposition temperature: 25 to 500 °C • Deposition films: •Oxide: Al2O3, HfO2, La2O5, SiO2, TiO2, ZnO, ZrO2, Ta2O5, SnO2, ITO, Fe2O3, Nb2O5 • Nitride: WN, Hf2N4, Zr3N4, AlN • Metal: Ru, Pt., W, Ni, Fe, Co •Plasma Mode: • For difficult nitrides and metals • Enables low temperature process • Ability to control stoichiometry • Plasma surface treatment • Faster deposition rate than Thermal ALD • Plasma Source: Ar, N2, O2, H2, NH3, CH4 NRF METROLOGY CAPABILITIES • SCI Filmtek 2000 spectrophotometer for measuring thickness ess and refractive index of multiple films including SOI, porous silicon and III-V heterostructures etc.. • Flexus 2320A film stress measuring system. • Nanospec 210 spectrophotometer for measuring film thicknesses of known refractive index. • M & M 6400 probe station with HP 4145 parametric analyzer Filmtek Reflectance curve for LPCVD nitride film • Miscellaneous microscopes, video cameras etc. • CDE ResMap 4 point probe for mapping sheet resistances. • Dektak 6 and 8 surface profilometers with extended vertical range and topology mapping capability (Dektak 8) ResMap resistivity contours NRF METROLOGY CAPABILITIES • Veeco Dimension 3100 Atomic Force Microscope NanoScope IV SPM Control Station supports all AFM /STM scanning techniques. Up to 10X faster topographical scanning, plus phase imaging in air with Tapping Mode. Includes Quadrex Extender Electronics and Q-Control for improved phase, sensitivity and image contrast; high-speed DSP and SPM computer interface electronics; ten micro-actuated probes (Model DMASP) SPECS: X-Y scan range: ~50 μm square Z (vertical) range: ~8 μm Vertical noise floor: <0.05 nm RMS Non-linearity (X-Y) <1% X-Y noise level: <2 nm RMS, 6 nm peak-to-peak (closed-loop feedback) Dimension CL, XY Closed-Loop SPM Scan Head Integrated Vibration Isolation Table & Acoustic Enclosure Dimension 3100 Scanning Probe Microscope performs all major AFM imaging techniques on samples up to 200mm in diameter / 12mm thick. Stage resolution: 2μm; bidirectional (x-axis: 4μm, Y-axis: 6μm), video optics (zoom w/ 150-675μm viewing area), Nanolithography Software allows user to build custom lithography programs to control the NanoScope and includes a lithography support note, a compiler, function libraries and sample programs. NRF OPTICAL METROLOGY Sopra GES5 Spectroscopic Ellipsometer • Spectral Range: 210 – 900 nm; upgradable for wider spectral range in DUV, NIR & IR • Spectrometer Accuracy .16 nm • Double Prism & Grating for stray light rejection & more accurate signal capture • PMT Detection + Photon counting method: better SNR (signal-to-noise ratio) eliminated need to converts signal with A/D converters & loss of signal • Photon Counting: SNR is constant over whole spectral range & does not interfere with measurement signal • Optical Fiber connects direct to spectrometer for reduced signal loss • Microspot formation by lens focusing for measuring pattern samples as small as 150 μm • Goniometer: variable angle from 7°to 90°, variable ± 0.01° • Typical Applications: • High-k: SiO2, Si3N4, SiNx, HfO2, Ta2O5, • Low-k: SiOC, SOG, Polymers… • Metals & Interconnects: Al, Cu, Cr, Mo, W, Pt., TiN, TaN, WSix, AlCu… • Lithography: AR coatings, BARC, SiOxNy • Semiconductors & Epi-layers: SOI, SiGe, Strained Si, SiC, Poly-Si, a-Si, HSG, III-V: AsGa, InP, GaN…, II-VI: CdTe, ZnSe… NRF Optical Metrology Wyco NT 3300 Optical Profiler • • • • • • • • • • Micro Connector Used for 3-dimensional, non-contact, surface profile measurements Vertical Measurement Range 0.1 nm to 1 mm; Vertical Resolution < 1 Å Ra, RMS Repeatability 0.01 nm Patterned films of 160 nm and up and thick films ≥ 3 μm Lateral spatial sampling 0.08 to 13.1 μm, vertical scan speed up to 7.2 μm/sec; Field-of-View 8.24 mm to 0.05 mm, reflectivity 1% to 100% Uses optical phase-shifting and white light vertical scanning interferometry Objectives 5.0X, 20X, 50X with 0.5, 1 and 2X extended magnification Uses a tungsten halogen lamp and automated filter selection Automated stage; ± 50.8 mm (±2 in.) X/Y translation, ±90° rotation, ±6° tip/tilt MEMS Heater Simultaneous measurement of X and Y profiles for contact holes NRF Custom Processing Capability Researcher loads parylene coater prior to deposition Automated custom XeF2 etcher for isotropic Si etching AMMT HF Vapor Etcher with electrostatic chuck for MEMS etching of SiO2 films on pieces to 6 inch substrates AMMT Porous Silicon Etcher NRF Custom Processing Capability Critical point dryer for cleaning delicate MEMs structures using liquid CO2 Researcher loads high temperature oxidation/anneal Furnace (1325 Deg C Denton Desk II Sputter Coater for SEM preparation of insulating samples