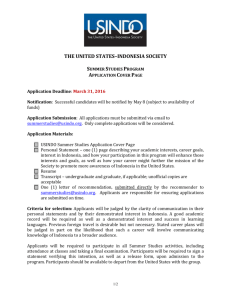

Indonesia

advertisement