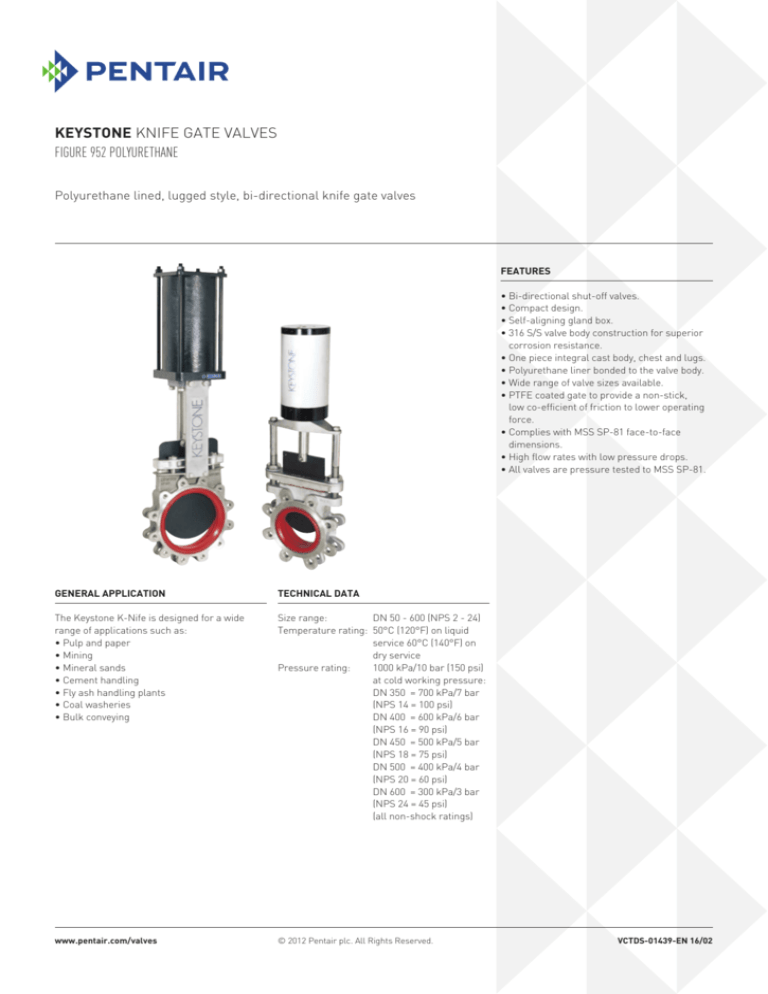

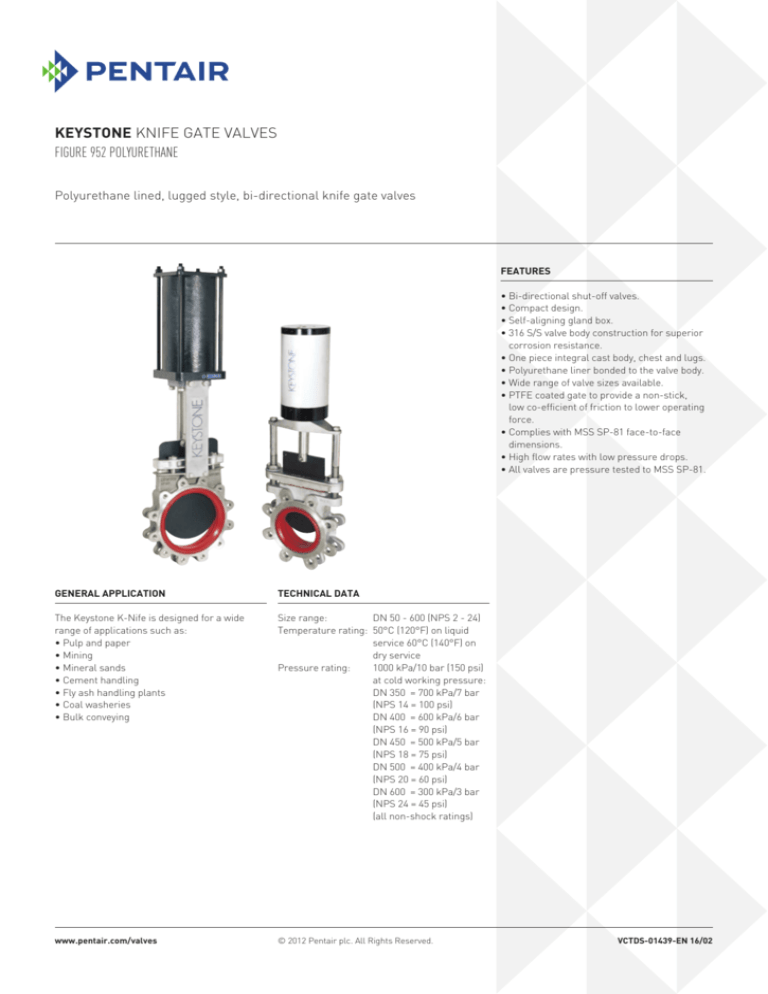

KEYSTONE KNIFE GATE VALVES

FIGURE 952 POLYURETHANE

Polyurethane lined, lugged style, bi-directional knife gate valves

FEATURES

• Bi-directional shut-off valves.

• Compact design.

• Self-aligning gland box.

• 316 S/S valve body construction for superior

corrosion resistance.

• One piece integral cast body, chest and lugs.

• Polyurethane liner bonded to the valve body.

• Wide range of valve sizes available.

• PTFE coated gate to provide a non-stick,

low co-efficient of friction to lower operating

force.

• Complies with MSS SP-81 face-to-face

dimensions.

• High flow rates with low pressure drops.

• All valves are pressure tested to MSS SP-81.

GENERAL APPLICATION

TECHNICAL DATA

The Keystone K-Nife is designed for a wide

range of applications such as:

• Pulp and paper

• Mining

• Mineral sands

• Cement handling

• Fly ash handling plants

• Coal washeries

• Bulk conveying

Size range:

DN 50 - 600 (NPS 2 - 24)

Temperature rating: 50°C (120°F) on liquid

service 60°C (140°F) on

dry service

Pressure rating:

1000 kPa/10 bar (150 psi)

at cold working pressure:

DN 350 = 700 kPa/7 bar

(NPS 14 = 100 psi)

DN 400 = 600 kPa/6 bar

(NPS 16 = 90 psi)

DN 450 = 500 kPa/5 bar

(NPS 18 = 75 psi)

DN 500 = 400 kPa/4 bar

(NPS 20 = 60 psi)

DN 600 = 300 kPa/3 bar

(NPS 24 = 45 psi)

(all non-shock ratings)

www.pentair.com/valves

© 2012 Pentair plc. All Rights Reserved.

VCTDS-01439-EN 16/02

KEYSTONE KNIFE GATE VALVES

FIGURE 952 POLYURETHANE

12

11

10

7

8

ØF

12

11

10

5

8

7

13

5

C1

13,14

C

3

9

6

9

3

6

11

2

2

1

4

4

D

B A

1

E

Note: DN 50 - 200 (NPS 2 - 8) valve illustrated.

PARTS LIST

No.

1

2

3

4

5

6

7

8

9

10

11

12

Description

Body

Gate

Gland box

Seat

Spindle

Gland packing

Bridge (DN 50 - 200 / NPS 2 - 8)

Upstand (DN 250 - 600 / NPS 10 - 24)

Pillar

Glandbox washer

Handwheel nut

Thrust washer

Handwheel

13

14

Clevis

All fasteners

Note: DN 250 - 600 (NPS 10 - 24) valve illustrated.

Ma­te­ri­al

316 S/S - Polyurethane lined

316 S/S (PTFE coated)

304 S/S

Polyurethane

303 S/S

K-LON

304 S/S

304 S/S or painted mild steel

304 S/S

Nylon

Leaded gunmetal

Nylon

S.G. Iron (rising DN 50 - 300 / NPS 2 - 12)

S/S (non rising DN 250 - 600 / NPS 10 - 24)

304 S/S

304 S/S

OPTIONS

• F738 Pneu­mat­ic actuators

• Electric actuators

• Bevel gear operators

• Chainwheels

• F459 Quick acting levers

(DN 50 - 200 / NPS 2 - 8)

• F791 So­le­noid valves

• Limit switches

• F793 Positioners

• F493 Pneu­mat­ic failsafe

• Safety guards and shrouds

2

KEYSTONE KNIFE GATE VALVES

FIGURE 952 POLYURETHANE

ØF

12

11

10

ØF

5

8

7

13

C1

C1

C

9

3

C

6

2

4

B A

D

B A

1

D

E

E

Notes: DN 250 - 600 (NPS 10 - 24) valve illustrated.

Number of lugs is dependent upon flange drilling.

Notes: DN 50 - 200 (NPS 2 - 8) valve illustrated.

Number of lugs is dependent upon flange drilling.

DIMENSIONS mm (inches)

Valve

size

DN (NPS)

50 (2)

65 (2½)

80 (3)

100 (4)

125 (5)

150 (6)

200 (8)

250 (10)

300 (12)

350 (14)

400 (16)

450 (18)

500 (20)

600 (24)

Bore

A

50 (1.97)

65 (2.56)

80 (3.15)

100 (3.94)

125 (4.92)

150 (5.91)

200 (7.87)

250 (9.84)

300 (11.81)

330 (13.00)

378 (14.88)

425 (16.73)

475 (18.70)

571 (22.48)

B

92 (3.62)

108 (4.25)

127 (5.00)

157 (6.20)

186 (7.32)

212 (8.35)

270 (10.63)

326 (12.83)

380 (15.00)

452 (17.80)

480 (18.90)

540 (21.25)

585 (23.03)

692 (27.25)

Rising spindle

(closed)

(open)

C

C1

264 (10.39)

295 (11.60)

284 (11.18)

316 (12.45)

324 (12.76)

391 (15.40)

358 (14.10)

425 (16.75)

450 (17.72)

519 (20.43)

487 (19.17)

579 (22.80)

602 (23.70)

746 (29.37)

726 (28.60)

908 (35.75)

825 (32.50)

1057 (41.60)

881 (34.70)

1144 (45.04)

968 (38.10)

1281 (50.43)

1095 (43.10)

1450 (57.10)

1192 (46.93)

1598 (62.91)

1400 (55.12)

1881 (74.06)

Non-rising

C

693 (27.30)

793 (31.22)

848 (33.40)

935 (36.81)

1084 (42.68)

1181 (46.50)

1369 (53.90)

D

49 (1.90)

49 (1.90)

52 (2.00)

52 (2.00)

58 (2.25)

58 (2.25)

71 (2.75)

71 (2.80)

76 (3.00)

76 (3.00)

89 (3.50)

89 (3.50)

114 (4.50)

114 (4.50)

E

159 (6.30)

177 (6.80)

192 (7.50)

222 (8.75)

256 (10.00)

285 (11.10)

325 (13.40)

406 (16.00)

474 (11.65)

520 (20.47)

584 (23.00)

628 (24.72)

696 (27.40)

822 (32.36)

ØF

200 (8)

200 (8)

200 (8)

200 (8)

300 (12)

300 (12)

300 (12)

400 (14)

400 (14)

400 (14)

400 (14)

600 (24)

600 (24)

600 (24)

Nom. mass

manual kg

(lbs)

7 (15)

8 (18)

10 (22)

12 (26)

18 (40)

22 (48)

34 (75)

47 (101)

74 (156)

93 (191)

121 (251)

170 (361)

212 (440)

312 (660)

Kv* (Cv❖) at

full open

223 (258)

368 (425)

557 (643)

909 (1050)

1416 (1635)

2112 (2439)

4065 (4695)

6850 (7912)

9863 (11392)

11858 (13696)

15590 (18006)

20165 (23291)

25117 (29010)

36896 (42615)

NOTES

Dimension D = The face to face dimension.

Dimension E = The maximum valve or upstand clearance dimension for installation.

Kv* = the flow rate of water in m3/hr that will pass through a valve with a differential pressure of 1 bar (100 kPa) at 20°C.

Cv ❖ = the volume of water in US gpm that will pass through a valve with a differential pressure of 1 psi at 60°F.

Cv = 1.155 Kv

Dimensions are nominal.

3

KEYSTONE KNIFE GATE VALVES

FIGURE 952 POLYURETHANE

PRESSURE/TEMPERATURE RATINGS

PRESSURE/TEMPERATURE GRAPH

Temperature °F

1500

(15)

200

300

400

AS

0

ASM

E1

TM

5

A1 0

05

AS

21

29

200

E

150

500

(5)

0

0

50

Max. limit for dry service

1000

(16)

Max. limit for liquid service

Pressure kPa (bar)

JIS 1

60

Polyurethane lined valves

1000 kPa/10 bar (150 psi) at 20°C (68°F)

935 kPa/9.35 bar (135 psi) at 50°C (120°F)

(max. for liquid service)

500

100

STANDARD SEAT DETAIL

Pressure psi

100

50

100

150

200

230

250

300

Polyurethane seat

Temperature °C

TYPICAL SPECIFYING SEQUENCE

Example:

Valve size

Figure number

F952

Trim code

193

End connections

AS 2129

JIS B2210

ASME B16.5

DIN 2501

BS 4504

ASME B16.5

Trim code

193

150

F952

193

AS 2129 E

DN 50 - 600 (NPS 2 - 24)

Lugged style rising and non rising spindle polyurethane bi-directional valve

Table C, D, E metric threads

Table 5, 10

Class 125 and 150 UNC threads

Table 10, 16

PN 10 and 16

Class 125 and 150 metric threads (for N.Z.)

Body

316 S/S/P.U.

Gate

316 S/S/PTFE*

Seat

Urethane

Gland box

304 S/S

Bridge

304 S/S

Spindle

303 S/S

Packing

K-LON

NOTES

* Gates are 316 S/S, coated with PTFE.

P.U. = Polyurethane lined.

Non-rising spindle design available upon request.

To minimize risk to personnel, Pentair recommend the use of purpose built guards and shrouds.

Refer to the Pentair data sheet or consult factory for details.

PENTAIR VALVES & CONTROLS

www.pentair.com/valves

All Pentair trademarks and logos are owned by Pentair plc. All other brand or product names are trademarks or registered marks of their respective owners.

Because we are continuously improving our products and services, Pentair reserves the right to change product designs and specifications without notice.

Pentair is an equal opportunity employer. © 2016 Pentair plc. All rights reserved.

4