Experiment 26

advertisement

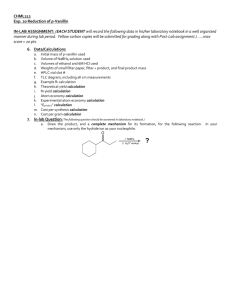

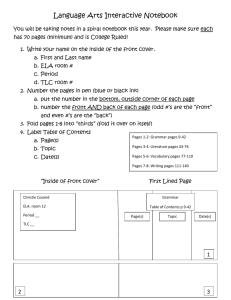

Experiment 20 Chemoselective Reduction with Sodium Borohydride O O H H HO C C O O + H3C O OCH3 CH2 CH3 NaBH 4 EtOH NaOH OCH3 acetic anhydride O OH 4-hydroxy-3-methoxybenzaldehyde (p-vanillin) OCH3 O O CH3 O CH3 4-acetoxy-3-methoxybenzaldehyde (vanillin acetate) 4-acetoxy-3-methoxybenzyl alcohol (vanillin alcohol) Figure 20.1 Acetylation of p-vanillin followed by chemoselective reduction. Introduction Chemoselective reductions of carbonyl compounds to the corresponding alcohols are very important functional group conversions in organic synthesis, yet there are very few laboratory experiments which focus on this particular concept. In this experiment, the flavoring additive vanillin with be acylated in order to produce a compound with two different carbonyl functional groups. Once acylated, the product will be reduced with sodium borohydride. The resulting product will illustrate the difference in selectivity of NaBH4 towards different carbonyl containing functional groups. The reaction will be followed using TLC analysis, and the purity of the product will be determined using HPLC analysis. Reactants and products will be characterized using 1H-NMR and IR spectroscopy. Reducing Agents The most common laboratory reagents for the reduction of a carbonyl group of an aldehyde or ketone to an alcohol are sodium borohydride (NaBH4) and lithium aluminum hydride (LAH), shown in Figure 20.2. Both of these compounds behave as sources of a hydride ion, which is a very strong nucleophile (see McMurry text, pages 609 and 709). H Na + H B H Li+ H H Al H H H Sodium borohydride H Hydride ion Lithium aluminum hydride Figure 20.2 Common reducing agents. Lithium aluminum hydride is a very powerful reducing agent and reacts not only with aldehydes and ketones, but also with many other carbonyl containing compounds such as esters, carboxylic acids, and amides. One disadvantage of LAH is that it reacts violently with protic solvents such as water and methanol, to produce metal hydroxides or alkoxides, and hydrogen gas, which could result in an explosion or fire. 169 Sodium borohydride is much milder, much more selective reducing agent than lithium aluminum hydride. Unlike lithium aluminum hydride, sodium borohydride will not reduce carbonyl-containing compounds such as esters, carboxylic acids, or amides, therefore an aldehyde or ketone can be reduced with sodium borohydride in the presence of these other types of functional groups. These reductions can be performed in a wide variety of solvents, such as aqueous methanol or ethanol, with a good to excellent yield. The key step in the metal hydride reduction of an aldehyde or ketone is transfer of a hydride ion from the boron atom of the reducing agent to the electropositive carbon of the carbonyl group to form a tetrahedral intermediate (Figure 20.3) called an alkoxide ion. The resulting alkoxide ion is protonated by the protic solvent to form a neutral alcohol. One mole of NaBH4 is a source of four hydride ions, therefore can react with four carbonyl groups to produce four moles of the product. Thus, one mole of the reducing agent reduces four moles of the carbonyl compound. 4 R O C O 4 H R C OH CH3CH2O H 4 R H H C H H H H B H H Figure 20.3 Mechanism for the sodium borohydride reduction of an aldehyde. Chromatographic Analysis All reactants and products in this experiment contain aromatic rings which are chromophores easily visualized using a UV lamp. It is also optional to stain the TLC plate with certain compounds that not only aid in the visualization of compounds, but also provide a method for determining which functional groups are contained within a molecule. A solution of 2,4-Dinitrophenylhydrazine (2,4-DNP) is a stain mainly used to detect aldehydes and ketones. When these types of carbonyl compounds react with 2.4-DNP, they form the corresponding hydrazone, which is usually yellow or orange, thus resulting in the spot on the TLC plate to appear colored. Interestingly, 2,4-DNP does not react with other carbonyl containing functional groups such as esters, carboxylic acids, and amides, therefore can be useful to distinguish between compounds containing more than one type of carbonyl functional group. R H C HN NH 2 HN O NO 2 N NO 2 + H R aldehyde or ketone NO 2 NO 2 product hydrazone (yellow-orange) 2,4-DNP (red-orange) Figure 20.4 Reaction between 2,4-DNP and an aldehyde or ketone. 170 IR Spectroscopy The products can be easily distinguished from the reactants using IR spectroscopy. The first step of the reaction results in the conversion of a hydroxyl group to an acetyl group. The phenolic O-H stretch typically appears as a broad absorption in the range of 3200-3600 cm-1. Also present is the C-O bond absorptions, which typically appear between 1000-1300 cm-1. It is interesting to note that a characteristic of esters is the presence of two of these absorption bands, one stronger and broader than the other. Aldehydes exhibit two C-H stretches around 2700 and 2800 cm-1, however these may be difficult to distinguish when broad O-H absorptions are present. Finally, a C=O stretching absorption would appear between 1680-1740 cm-1. Make note that if an acetyl group was successfully added onto the reactant, a second C=O stretching absorption could appear in this region. The second step of the reaction results in the conversion of a carbonyl group to a hydroxyl group. IR spectroscopy can certainly be used to determine whether the reducing agent reduces one, or both, of the carbonyl substituents based on the appearance or disappearance of certain types of absorptions characteristic of those types of carbonyl groups. The IR spectra of the reactants and products are shown in Figure 20.5. NMR Spectroscopy The 1H NMR spectra of the reactant and products are shown in Figure 20.6 The chemical shift of a phenolic hydrogen in proton NMR varies depending on the purity of the sample, the temperature, and the sample solvent. It typically appears in the range of 5.0-10.0 ppm, depending on the experimental conditions. Hydrogens on the carbon bearing the hydroxyl group are deshielded by the oxygen atom, and typically appear in the range of 3.5-4.5 ppm. Hydrogens attached to carbons to the carbonyl typically resonate between 2.0-3.0 ppm. The aldehyde proton signal is very distinctive, appearing as a singlet 10.0 ppm. Very few signals appear that far downfield in a 1H NMR spectrum. Objectives In this experiment you will synthesize acetylate p-vanillin using acetic anhydride. Once acylated, the product will be reduced using NaBH4 in ethanol. The identity and purity of the product will be analyzed using TLC and HPLC analysis. Finally, reactants and products will be characterized using IR and 1H NMR spectroscopy. Experimental PART 1: Synthesis: Preparation of Acylation product Mix ~0.76 g of p-vanillin and 12.5 mL 10% NaOH in a 125 mL Erlenmeyer flask containing a stir bar. Stir for 2-3 minutes. Add 15.0 g of ice to flask, then add 2.0 mL acetic anhydride while stirring. Place a large cork loosely in the top of the flask, and allow reaction to stir for 15 minutes. Record any observations in your laboratory notebook. 171 Purification of Acylation product: If a white precipitate forms: o Suction filter to isolate the crude solid. Use ~25 mL ice cold water to help transfer solid from reaction flask to funnel, and to rinse solid once filtered. o Transfer crude solid to a 50 mL Erlenmeyer flask. Recrystallize the solid in ~3 mL hot ethanol. Once dissolved, cool to room temperature, and then place in an ice bath for 15 minutes to induce crystallization. o Suction filter to isolate the pure solid. Use ice cold ethanol to help transfer the solid to the funnel, and to rinse the solid once filtered. If any solid appears in the filtrate, repeat filtration process. o Prepare an HPLC sample by transferring 2-3 crystals to an autosampler vial and dissolving completely in the provided HPLC solvent (2:3 ethyl acetate/hexane). Submit this sample for analysis. o Prepare a TLC sample by transferring 2-3 crystals to a small sample vial and dissolving in ½ mL reagent acetone. Label this vial clearly ACYLATION PRODUCT and use during Product Analysis below. o Transfer the solid from the funnel to a preweighed large filter paper. Secure with a small amount of tape and submit to instructor to dry until next lab period. o Once dry, reweigh solid to obtain a final product mass, calculate % yield, and obtain an experimental melting point of this solid. Complete Tables 20.1 and 20.3 on the final lab report. If a colorless liquid or oil forms: o Transfer reaction solution to a separatory funnel, using ethyl acetate to aid transfer if necessary. o Extract the solution 2X with 15 mL ethyl acetate (review Experiment 6 if necessary). o Wash the combined organic layers with 25 mL 1M NaOH. Check pH of aqueous solution. Continue to extract with NaOH until the aqueous layer is strongly basic (pH>9). o Dry organic layer over MgSO4. Decant the solution into a preweighed 250 mL beaker containing a few boiling chips, and evaporate solvent on a warm hotplate (setting of 3, NO HIGHER!) to yield the solid product. o Prepare an HPLC sample by transferring 2-3 crystals to an autosampler vial and dissolving completely in the provided HPLC solvent (2:3 ethyl acetate/hexane). Label this vial clearly ACYLATION PRODUCT and store in lab drawer until next lab period. o Prepare a TLC sample by transferring 2-3 crystals to a small sample vial and dissolving completely in reagent acetone. Label this vial clearly ACYLATION PRODUCT and store in lab drawer until next lab period. o Cover the beaker containing the product with a Kim Wipe sheet and secure with a rubber band. Allow the product to dry until the next lab period. o Once dry, reweigh solid to obtain a final product mass, calculate % yield, and obtain an experimental melting point of this solid. Complete Tables 20.1 and 20.3 on the final lab report. 172 Product Analysis: HPLC Analysis Compare the HPLC results of the ACYLATION PRODUCT sample submitted to the standard chromatogram. Identify any compounds present in samples, and quantify compounds present. Complete Table 20.5 on the final lab report. TLC Analysis Perform a TLC experiment on the ACYLATION PRODUCT sample along with the provided standard of p-vanillin. Develop this plate in 2:3 ethyl acetate/hexane and visualize under UV lamp. Using tweezers, dip this plate in 2,4-DNP TLC stain. Blot excess stain on a paper towel, before transferring back to lab hood. Once completely dry, the 2,4-DNP reagent will produce a dark orange spot with any compound containing an aldehyde functional group. Sketch a diagram of this plate in your laboratory notebook, complete with color descriptions of the spots which appear. Complete Table 20.6 on the final lab report. PART 2: Synthesis: Reduction of Acylation product Record product mass from previous experiment. Transfer solid to 100 mL beaker. Add 5 mL ethanol, and swirl to mix completely. Hold the beaker and swirl directly on the surface of a warm hotplate (setting of 3) to dissolve solid completely. Lower the beaker into a shallow water bath, cooled with a few ice cubes. Weigh ~0.30 g of NaBH4. Add a small portion of this solid to the beaker and stir with glass rod (CAUTION! Do NOT add large amounts of NaBH4 all at once!). Continue adding the NaBH4 in small portions while stirring over a period of 2 minutes. Stir the reaction solution every few minutes for a total of 15 minutes in the cold water bath, then for an additional 15 minutes at room temperature. After 30 minutes, remove 1-2 drops of the reaction solution with a pipet and transfer to a small test tube. Add ½ mL reagent acetone to prepare a TLC sample of the CRUDE REDUCTION PRODUCT (the solid will not completely dissolve). Perform a TLC experiment on this reaction mixture along with the provided p-vanillin standard, and the ACYLATION PRODUCT sample prepared during the previous lab period. Develop the plate in 2:3 ethyl acetate/hexane, and visualize under a UV lamp. If there is any evidence of reactant present, stir the reaction for an additional 15 minutes and repeat the TLC analysis until there is no longer evidence of the starting material, thus indicating that the reaction is complete. Once complete, add 10 mL water to the reaction mixture. Stir this solution for an additional 5 minutes. Purification of Reduction product: Transfer the reaction solution to a separatory funnel. Extract the aqueous layer twice with 10 mL diethyl ether (review Experiment 6 if necessary). Wash the combined organic layers with 10 mL water, and then 10 mL saturated NaCl. 173 Dry the organic layer over MgSO4. Decant the solution into a preweighed 50 mL flask, and clamp to a ring stand. Evaporate the solvent by blowing air gently into the flask. The product will be a colorless, viscous oil. Reweigh the flask to obtain a final product mass, and calculate % yield. Complete Tables 20.2 and 20.4 on the final lab report. Add 3 mL reagent acetone directly to the flask, and swirl to dissolve the oily product. Use this solution as your TLC sample for the PURE REDUCTION PRODUCT. Prepare an HPLC sample of the PURE REDUCTION PRODUCT by transferring 2 drops of the liquid sample (in acetone from above) to an autosampler vial, and dissolving completely in the provided HPLC solvent (2:3 ethyl acetate/hexane). Submit this sample for analysis. Proceed to Product Analysis. Product Analysis: HPLC Analysis Compare the HPLC results of the PURE REDUCTION PRODUCT sample to the standard chromatogram. Identify any compounds present in the sample, and quantify compounds present. Complete Table 20.5 on the final lab report. Compare the HPLC results of the ACYLATION PRODUCT sample to the PURE REDUCTION PRODUCT sample. Was the acylation product pure when you started the reduction portion of the experiment? TLC Analysis Perform a final TLC experiment on the PURE REDUCTION PRODUCT sample along with the provided standards of p-vanillin, vanillin acetate, vanillyl alcohol, and vanillin alcohol. Develop this plate in 2:3 ethyl acetate/hexane and visualize under UV lamp. Sketch a diagram of this plate in your laboratory notebook. Using tweezers, dip this plate in 2,4-DNP TLC stain. Blot excess stain on a paper towel, before transferring back to lab hood. Once completely dry, the 2,4-DNP reagent with produce a dark orange spot with any compound containing an aldehyde functional group. Sketch a diagram of this plate in your laboratory notebook, complete with color descriptions of the spots which appear. Complete Table 20.7 on the final lab report. IR Analysis Using the provided spectra in Figure 20.5, identify all characteristic absorptions of reactants and products. Complete Table 20.8 on the final lab report. NMR Analysis Using the provided spectra in Figure 20.6, identify and tabulate all characteristic resonances of reactants and products. Complete Table 20.9 on the final lab report. 174 WASTE MANAGEMENT Place all solid waste into the container labeled “SOLID WASTE” located in the waste hood. Place all liquid waste into the container labeled “LIQUID WASTE”. Place any used melting point capillaries and TLC capillaries in the “BROKEN GLASS” container. TLC plates and filter papers can be discarded in the yellow trashcan. References McMurry, John. (2008). Organic Chemistry, 7th ed. Belmont: Thomson/Brooks/Cole. Baru, A. and Mohan, R. (2005). The Discovery-Oriented Approach to Organic Chemistry. Selective Reduction in Organic Chemistry: Reduction of Aldehydes in the Presence of Esters using Sodium Borohydride. Journal of Chemical Education. 82 (11): 1674-1675. 175 2843, 2751 3374 1673 1291 2845, 2753 1756 1126 1690 1207 3395 1150 1762 1197 Figure 20.5 IR spectra of reactants and products. 176 7.04 1H, d CDCl3 NMR Solvent H2,6 7.43 2H, m 6.21 1H, s O H1 C 9.83 1H, s 6 3.97 3H, s 2 5 OCH3 3 OH H2,6 7.49 2H, m CDCl3 NMR Solvent 4 7.22 1H, d O 3.91 3H, s 2.35 3H, s H1 C 6 2 5 OCH3 3 9.93 1H, s O CH3 4 C CDCl3 NMR Solvent O H2,6 6.90 2H, m 7.01 1H, d 3.84 3H, s CH2 OH 2.31 3H, s 7 1 2 6 5 4.62 2H, s 5.30 1H, s Figure 20.6 1H-NMR spectra of reactants and products. 177 OCH3 3 O C O CH3 4 178 Final Lab Report Due Date_______ Names______________________________ ______________________________ Exp. 20: Chemoselective Reduction with Sodium Borohydride EXPERIMENTAL RESULTS (Tables in INK only!) Table 20.1 Acylation Experimental Results Table 20.2 Reduction Experimental Results Theoretical yield (g) Actual yield (g) Percent yield Product Appearance Experimental Melting Point (oC) Theoretical yield (g) Actual yield (g) Percent yield Product Appearance Table 20.3 Acylation Green Chemistry Results Table 20.4 Reduction Green Chemistry Results Atom Economy (%) Experimental Atom Economy (%) “Eproduct” Cost per synthesis ($) Cost per gram ($/g) Atom Economy (%) Experimental Atom Economy (%) “Eproduct” Cost per synthesis ($) Cost per gram ($/g) Table 20.5 HPLC Analysis Sample ACYLATION PURE REDUCTION PRODUCT PRODUCT Retention Area Retention Area Times Percent Times Percent (min) (min) Standard Compound Retention Times (min) p-vanillin Vanillin acetate Vanillin alcohol Vanillyl alcohol Table 20.6 TLC Analysis—Part 1 Compound Part 1 Standard Sample Rf Rf TLC Diagram Table 20.7 TLC Analysis—Part 2 Compound p-vanillin p-vanillin Vanillin acetate Vanillin alcohol Vanillin acetate Vanillyl alcohol 179 Part 2 Standard Sample Rf Rf TLC Diagram Table 20.8 IR Analysis Base Values p-vanillin Vanillin acetate Vanillin alcohol Frequency (cm-1) Frequency (cm-1) Frequency (cm-1) Functional Group Frequency (cm-1) 3200-3600 1000-1300 1680-1740 2700-2800 OH stretch C-O stretch C=O stretch Aldehyde C-H stretch (2) Table 20.9 1H NMR Analysis p-vanillin O Vanillin acetate H1 C O C H1 Vanillin alcohol CH2 OH H1 6 H1 6 2 7 1 H1 2 6 2 5 H2,6 OCH3 5 5 OCH3 OCH3 H2,6 3 3 O OH C 4 3 H2,6 O C CH3 CH3 4 4 O H3 H3 H4 H5 H3 O H4 H5 H4 H5 H7 DISCUSSION/CONCLUSIONS (In the space provided, briefly answer the following questions. Use numerical values to support conclusions where applicable.) O O H C O O C H3C OCH3 OH 4-hydroxy-3-methoxy benzaldehyde (p-vanillin) $33.00/100g 1. CH3 NaBH 4 sodium borohydride $74.50/100g C O H C CH3 NaOH CH3CH2OH ethanol $20.60/1L acetic anhydride $39.20/500mL OCH3 H3C O C O 4-acetoxy-3-methoxy benzaldehyde (vanillin acetate) $190.20/100g OCH3 H3C O C 4-acetoxy-3-methoxy benzyl alcohol O Based on your HPLC analysis, did you synthesize only the desired product during the first step of the synthesis, or were other products formed? Did you synthesize only the desired product during the second step of the synthesis? Identify any compounds present in your sample chromatograms and give actual area percent values for each. If more than one product formed, briefly explain why this occurred. 180 2. What is one type of IR absorption band that could be used to indicate that the conversion from the aldehyde to the alcohol took place? What is the typical frequency for this type of absorption? What is the actual frequency of the absorption in the provided spectrum? 3. What is one signal in the 1H NMR spectrum that indicates that the reduction took place? What are the typical chemical shifts that these types of protons may appear? What is the actual chemical shift of this proton signal? 4. Once stained, how was the TLC plate used to indicate conversion of the reactant to the product alcohol? In your answer, briefly describe the Rf values and appearance of spots. 5. Draw the product, and a complete mechanism for its formation, for the following reaction. In your mechanism, use only the hydride ion as your nucleophile. O H O Li H3C C CH2 CH2 C OCH3 H Al H CH3CH2OH H **Attach sample chromatograms!** 181