Toyota Plant

advertisement

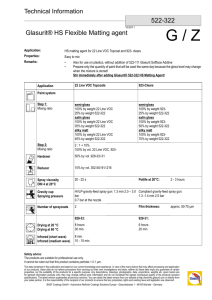

Environment & Power Systems International VOCGEN 525kW Industrial Gas Turbine Genset and CHP Systems featuring Gas Turbine VOC Oxidizer Technology (GTO) VOCGEN Value-Driven Energy and Environmental Solutions Copyright © 2011 Environment & Power Systems International Update 7/23/2013 Copyright 2011 1 Economic Solutions for a Sustainable Industrial Future Advantages and Benefits VOC emissions are a waste-to-energy opportunity fuel VOC destruct removal efficiencies (DRE) achieve EPA and State air pollution control standards VOCGEN Project economics provide a compelling case for use of energy efficient combined heat and power for manufacturing industries Operational savings provide a superior return on investment when compared to conventional air pollution controls The technology achieves a ≥50% reduction in carbon emissions compared to purchased regional conventional generation 7/23/2013 Copyright 2011 2 VOC Chamber Patent Owner Environment & Power Systems International Vericor Power Systems Engine Manufacturer 7/23/2013 Copyright 2011 3 Garrett IE 831-1000 Industrial Gas Turbine manufactured for over 45 years with over 500 engines operating worldwide Garrett IE 831-1000 Industrial Gas Turbine With VOC Destruct Combustion Chamber 7/23/2013 Copyright 2011 4 7/23/2013 Copyright 2011 5 Gas Turbine VOC Destruct Combustion Chamber Concept Diagram Natural Gas Pilot Fuel VOC Destruct Chamber Primary Combustor Inlet Air 6,200scfm @ ISO Conditions 2,500-3,000 ⁰ F 95% - 99.9% VOC Destruct Exhaust Air 800-925⁰F and ≈17,500scfm 4,500 lbs/hr steam ≤2,500 ⁰ F Compressor Turbine VOC Laden Air 600 ⁰ F G E A R B O X Generator Clean Exhaust Air Heat Recovery 525 kWh @ ISO Cond. Electric Output 480V The Garrett IE831-1000 (ASE8) is a single-spooled gas turbine with a two-stage centrifugal compressor & three-stage axial turbine. 7/23/2013 Copyright 2011 6 Conceptual Illustration VOC Destruct Combustion Chamber 7/23/2013 Copyright 2011 7 ASE8™ Gas Turbine in a Broad Range of Industrial Applications Worldwide Rugged Dependability Reliable Energy for Critical Operations Compact Installation Designed for Extreme Environments Energy Efficiency and Carbon Reduction Commercial Ready Equipment The outdoor-rated prototype ASE8 engine with the patented VOC reaction chamber (left) The VOC pentane was abated pursuant to plant air quality permit requirements of the State of California 4,000 lbs/hr steam was recovered in a heat recovery steam generator (HRSG) and utilized in the production process. 7/23/2013 Copyright 2011 9 Vericor Power Systems ASE™8 Gas Turbine Overhaul & Repair Facility in New Orleans Vericor Power Systems operates an ASE8 overhaul and repair facility in Harvey, LA. The facility offers full aftermarket support including spare parts, field service, repair and overhaul services, and long term maintenance contracts for Vericor's fleet of ASE™8 aero derivative gas turbines. As of 2009, there are 500 ASE8 gas turbines in use worldwide in industries such as oil and gas, food processing, telecommunications and hospitals, as well as in industrial and offshore power generation applications. The ASE8 is the current designation of the popular IE831 industrial gas turbine. A key benefit of this facility is that the OEM offers customers complete aftermarket services and support in a more cost-competitive and effective manner. Vericor's facility ensures that customers will receive the highest quality ASE8 spare parts and services at competitive pricing -- backed by the technical know-how and expertise of the OEM. About Vericor Vericor is an MTU Aero Engines Company based in Alpharetta, Georgia USA. Vericor is the OEM for the ASE series aeroderivative gas turbines, and supplies systems and related services for marine, oil and gas and power generation customers. For additional information visit www.vericor.com 7/23/2013 Copyright 2011 10 Two Options for Facilities with Existing Equipment Option A: Replace RTO with VOCGEN system VOC Laden Air Carbon Wheel Conc. VOC VOCGEN 6,000scfm Option B: Run VOCGEN parallel to RTO for redundancy /backup VOC Laden Air Carbon Wheel Conc. VOC VOCGEN Examples Only Actual Project Conditions are Subject to Feasibility Analysis 7/23/2013 RTO 6,000scfm Copyright 2011 11 Option A – Replace RTO System with VOCGEN System Existing New Steam 4.0 MMBtu/HR VOCGEN Gas Thermal Oxidizer (GTO) Exhaust Air Desorption ≈25 kW ≈75 kW VOC Laden Air Carbon Wheel* 6,000 scfm 180⁰F Chiller or Water Fogger 200 PSI Natural Gas Utility Natural Gas Clean Air 60⁰F VOCGEN Heat Recovery Steam Generator (HRSG) 925 ⁰F ≈50 kW Gas Booster Compressor Net Electricity 377kW (w/chiller, voc concentrator, and NG compressor) 7/23/2013 Copyright 2011 12 Option B – Operate VOCGEN Parallel to RTO Existing New New Existing VOCGEN Gas Thermal Oxidizer (GTO) Exhaust Air Desorption Carbon Wheel VOC Laden Air Optional VOC Air Flow to RTO RTO 6,000scfm ≈25 kW ≈75 kW to Chiller Chiller or Water Fogger Exhaust Air 60⁰F VOCGEN Natural Gas 200 PSI Utility Natural Gas Gas Booster Compressor Clean Air 925 ⁰F HRSG to Carbon Wheel Desorption and / or Exhaust Stack ≈50 kW Steam 4.5 MMBtu/HR Electricity 375 kW 4.5klbs/34.5lbs/HR = 130.4 Boiler HP (1,000 PPH Steam @ 0 psig 212°F ≈ 1000 kBtu/HR) 4,500lbs Steam ≈ 4.5 MMBtu/HR (NG Offset) 7/23/2013 Copyright 2011 13 EPSI Genset PCL Control VOC CONCENTRATOR EXHAUST STACK VOC Laden Air Stream <6,200CFM, 390⁰F @ Sea Level EPSI Genset & Slave Equipment Status Info Exhaust Stage To Atmosphere VOC Laden Air Stream Optional Desorption Return Air Stream MOTOR CONTROL CABINET 360⁰F From EPSI Genset To VOC Concentrator Electrical Power Control Signals from Genset PLC Operation Status From Booster Compressor Electrical Power Optional Power Supply For Compressors PT 200psi Gaseous Fuel Natural Gas BOOSTER COMPRESSOR SKID Redundant System w/ Dual Compressors FUEL RECEIVER TANK Variable Sizing Alternate Gaseous Fuel From Pressurized Storage Tank Propane, Butane, CNG Liquid Fuel Diesel Jet-A Gasoline JP-4 & JP-5 Ethanol/ biofuel And Equipment Control Optional For Maintenance EPSI Genset Data Acquisition Shop Air Line Liquid Fuel Supply Line To Optional EPSI Onboard Pump Damper Position Damper Motor Control Concentrator Motor Status & Control Air Stream to Genset Temperature 4160, 2740, 480 EPSI Genset Includes optional Step Down Transformers Generated Power To Grid Or Facility 525kW EPSI GENSET SKID Pressure & Valve Control Signal To/From Genset PLC w/ Onboard PLC Switch Gear EX Genset / Concentrator PLC Communications VOC CONCENTRATOR Remote EPSI Genset Control Panel Onboard Fire Suppression Rechargeable CO2 Tank 17,500 CFM 925⁰F H Allen Bradley Touch Pad Gas Turbine Engine & Controls w/ VOC Destruct Chamber & Onboard Master PLC / Modem COMPUTER W/ MODEM Remote Data Access & Equipment Monitoring Engine Oil Presser Engine Oil Level Engine Speed Engine EGT Fuel Inlet Pressure Engine Room Fan Engine Room Temperature Tire System Status Ambient Air Temperature Outside Humidity Potable Water 7/23/2013 Copyright 2011 14 Next Generation VOCGEN Generator Packages 525 kW Continuous Power 4,000 lbs/Hour Steam (w/HRSG) 6,200 SCFM/Hr Inlet Airflow (ISO Conditions) Functional Specifications and Designs by Environment & Power Systems International and Gas Technology Institute 7/23/2013 Copyright 2011 15 Environment & Power Systems International - Business Partners Vericor Power Systems Gas Turbine Engines and Services IMCOR Manufacturing VOCGEN Design & Contract Packager Petrotech, Inc. VOCGEN Automation & Controls GLHN Architects & Engineers, Inc. Project Engineering Design & Commissioning 7/23/2013 Copyright 2011 16 7/23/2013 Copyright 2011 17 Environment & Power Systems International VOCGEN Steven E. Sexton (520) 414-9472 stevesexton@vocgen.com http://www.vocgen.com 7/23/2013 Copyright 2011 18