Roundtable on Sustainable Palm Oil

advertisement

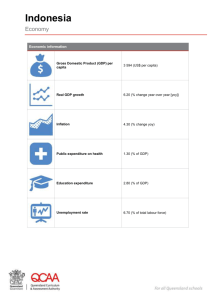

Roundtable on Sustainable Palm Oil Supply Chain Certification Report Report no.: SCCS_15011 Assessment against RSPO Supply Chain Certification Systems November 2011 Wilmar International Indonesia PT Wilmar Cahaya Indonesia Tbk Cikarang – West Java, Indonesia Date of assessment : October 9, 2014 Report prepared by : Hendra Fachrurozy (RSPO Lead Auditor) Certification decision by : Muhammad B. Asana (Head of Certification Body PT TUV Rheinland Indonesia) Certification Body : PT TUV Rheinland Indonesia Menara Karya, 10th Floor Jl. H.R. Rasuna Said Block X-5 Kav.1-2 Jakarta 12950,Indonesia Tel: +62 21 57944579 Fax: +62 21 57944575 www.tuv.com/id TABLE OF CONTENTS 1.0 SCOPE OF SUPPLY CHAIN CERTIFICATION ASSESSMENT .................................. 3 1.1 Executive Summary and Scope of Assessment .................................................................................. 3 1.2 Certification Details .............................................................................................................................. 3 1.3 Organisational Information / Contact Person ....................................................................................... 3 1.4 Actual Receipt material and sold product volumes............................................................................. 4 1.5 Summary of Previous Assessment ...................................................................................................... 5 2.0 ASSESSMENT PROCESS ........................................................................................... 6 2.1 Certification Body ................................................................................................................................. 6 2.2 Qualifications of Lead Assessor and Assessment Team .................................................................... 6 2.3 Assessment Methodology & Agenda ................................................................................................... 7 3.0 ASSESSMENT FINDINGS ............................................................................................ 8 3.1 Description of Supply Chain Management System ............................................................................ 8 3.2 Identified Non-conformances against RSPO SCCS Requirements, Corrective Actions Taken and Auditors Conclusions ........................................................................................................................ 14 3.3 Conclusion and Recommendation for RSPO Supply Chain Certification ......................................... 15 4.0 CERTIFIED ORGANISATION’S ACKNOWLEDGEMENT OF INTERNAL RESPONSIBILITY ...................................................................................................... 16 4.1 Date of Next Surveillance Visit ........................................................................................................... 16 4.2 Acknowledgements of Internal Responsibility and Formal Sign-Off by Client .................................. 16 APPENDICES ................................................................................................................... 17 Appendix 1 : Details of Supply Chain Certification Certificate ................................................................. 17 Appendix 2 : List of Abbreviations ............................................................................................................ 19 Appendix 3 : Observations and Opportunities for Improvement.............................................................. 19 Appendix 4 : Supply Chain Certification Audit Closing Meeting Summary ............................................. 20 Appendix 5 : List of supplier and buyer .................................................................................................... 21 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 3 of 21 1.0 SCOPE OF SUPPLY CHAIN CERTIFICATION ASSESSMENT 1.1 Executive Summary and Scope of Assessment PT Wilmar Cahaya Indonesia Tbk – Cikarang plant is foreign investment company under Wilmar International group, which is engaged in the processing of palm kernel oil to be their derivatives in the form of edible oil such as Refined Palm Kernel Olein (RBD PKOL) and Refined Palm Kernel Stearin (RBD PKST) by fractioning and refining process. The operations of PT Wilmar Cahaya Indonesia Tbk – Cikarang plant were assessed against Module B and C of the RSPO Supply Chain Certification (SCC) document (November 2011). The scope of the Supply Chain Certification assessment covers the implementation of the Segregation (SG) and Mass Balance (MB) supply chain model for all edible oil products produced by PT Wilmar Cahaya Indonesia Tbk – Cikarang Plant. This is not a multi-site certification. According to information stated on Bussiness permit no. 01/32/IU/I/PMDN/INDUSTRI/2013 dated on January 15, 2013 the mill has capacity of production are 36,000 MT for vegetable oil. The volume of palm oil product was sold by PT Wilmar Cahaya Indonesia in year 2013 and forecase year 2014. Product Type Product sold for year 2013 Projection for year 2014 RKO 11,669.82 12,000.00 RKL 7,066.09 9,600.00 RKS 0.00 3,600.00 RHKL 1,904.50 2,400.00 RHKS 2,877.15 3,600.00 CBR 0.00 4,800.00 CBS 0.00 12,000.00 The assessment was carried out on October 9, 2014 and a total of 2 (two) non-conformities were found during assessment. 1.2 Certification Details The details of RSPO certification of PT Wilmar Cahaya Indonesia Tbk – Cikarang plant are as per the table below Table 1 : RSPO Certification details of PT Wilmar Cahaya Indonesia Tbk – Cikarang plant RSPO Membership no. : 2-0017-05-000-00 on behalf Wilmar International Limited Membership starting on : August 15, 2005 RSPO Supply Chain Certificate no. : 824 503 15011 January 27, 2015 & January 26, 2020 Date of RSPO Supply Chain Certificate Refer to Appendix 1 for further details of the RSPO Supply Chain certificate. & Validity : 1.3 Organisational Information / Contact Person Contacts details of the company are as follows: QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 4 of 21 Company Name : PT Wilmar Cahaya Indonesia Tbk Address : Head Office : Jl. South Industry 3, Jababeka industry areas II Block GG 1, Cikarang – West Java, Indonesia Cikarang Plant : Jl. South Industry 3, Jababeka industry areas II Block GG 1, Cikarang – West Java, Indonesia Contact Person : Neni Kurniawati Position : Management Representative Telephone / Fax : +62-021-29380777 / +62-021-8937143 Email : neni.kurniawati@wilmar.co.id 1.4 Actual Receipt material and sold product volumes. Table 2: Records of Certified Material Recived/ Purchased * RSPO Certificate Number Supplier - - Product UTZ Number - - Volume - Note : *). This is main assessment for PT Wilmar Cahaya Indonesia Tbk so that auditee is not purchase raw material as certified claim Table 3: Records of Certified Palm Oil Product Sold* RSPO Certificate Number Buyer - - Product UTZ Number - - Volume - Note : *). This is main assessment for PT Wilmar Cahaya Indonesia Tbk so that auditee is not purchase raw material as certified claim Table 4 : Records of Material Received/ Purchased Supplier RSPO Certificate Number Product UTZ Number Volume (MT) Status / Model SC Period of Januari to December 2013 PT Wilmar Cahaya Indonesia – Pontianak - PKO - 25,522.38 - PT Sari Agrotama Persada – Palembang - PKO - 12,942.65 - Total 38,465.03 Period of Januari to September 2014 PT Wilmar Cahaya Indonesia – Pontianak - PKO - 20,954.80 - PT Sari Agrotama Persada – Palembang - PKO - 10,185.85 - Total 31,140.65 Note : - QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 5 of 21 Table 5 : Records of Palm Oil Product Sold RSPO Certificate Number Buyer Period of Januari to December 2013 PT Unilever Indonesia – Surabaya PT Sinar Antjol - PT Tempo Nagadi - Multi Commodity International LTD - PT Ayu Naturally Cemerlang - PT Wilmar Nabati Indonesia – Gresik* PT Lautan Krimerindo Natural PT Kievit Indonesia Pasar Rebo – PT Kievit Salatiga* – Indonesia Product 6,889.04 - RKO - 3,818.32 - RKO - RKL - HKL RHKL IV 6-7 PO1000000396 - RHKL IV 6-7 - RHKL IV <1 CU-RSPO SCCS829955 Status / Model SC - RKL - Volume (MT) RKO RKO 185 0 2248 001 UTZ Number - 752.46 - 210.00 - 4,557.00 - 1.50 - 2,507.59 MB 266.81 - 481.91 - 289.92 SG & MB RHKL IV <1 - 865.86 PT Gandum Mas Kencana - RHKS - 1,711.96 - PT Freyabadi Indotama - RHKS - 882.49 - PT Pusan Manis Mulia - RHKS - 282.70 - Total 23,517.56 Period of Januari to September 2014 PT Unilever Indonesia – Surabaya* PT Sinar Antjol - RKO - 4,068.73 - RKO - 1,929.29 - RKO PT Wilmar Nabati Indonesia – Gresik* 185 0 2248 001 1,005.39 PO1000000396 RKL HKL PT Sayap Mas Utama - RKO 7,360.56 - 803.61 408.59 PT Tempo Nagadi - RKO - PT Royal Industries Indonesia - RKO - 16.00 PT Ayu Naturally Cemerlang - RKL - 19.00 PT Lautan Natural Krimerindo - RHKL - 827.35 PT Freyabadi Indotama - RHKS - 610.91 PT Gandum Mas Kencana - RHKS - 1,495.17 PT Pusan Manis Mulia - RHKS - Total MB 2,200.24 304.35 21,049.19 Note : *). Not claim as certified product 1.5 Summary of Previous Assessment There is no summary of previous assessment audit, due to this is first SCCS audit for PT Wilmar Cahaya Indonesia Tbk – Cikarang Plant. QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 6 of 21 2.0 ASSESSMENT PROCESS 2.1 Certification Body PT TUV Rheinland Indonesia is member of Group TÜV Rheinland Group, a global leader in independent testing and assessment services. The TÜV Rheinland Group was established in 1872 with offices located in over 490 locations in 62 countries on all five continents. PT TUV Rheinland Indonesia offers certification for a wide range of management systems according to established international standards including ISO 9001, ISO 14001, OHSAS 18001, SA 8000, RSPO, ISPO, ISCC, Timber Legality Verification (TLV), as well as CDM Validations and Verifications, RSPO (RSPO-ACC-013 dated on June 06, 2014) and ISPO (LS-P&K-005-ISPO dated on May 10, 2012). PT TUV Rheinland Indonesia’s office is located in Jakarta, Indonesia. 2.2 Qualifications of Lead Assessor and Assessment Team Name Position Hendra Fachrurozy Lead Auditor Heni Handayani Auditor (Trainee) Qualifications / Experience Education: Bachelors Degree in Forestry - Bogor Agriculture Institute. Indonesia, (1995 to 2000). Trainings attended: ISO 9001:2008 lead auditor course - Neville Clark (2011); ISO 14001:2004 lead auditor course – TUV Rheinland Indonesia (2011); SMK3 auditor course – Department of Manpower and Transmigration of The Republic of Indonesia (2009); Sustainable Forest Management (SFM) - Forest Stewardship Council (FSC) system training; Chain of Custody training for FSC System; Sustainable Forest Management (SFM) – Forestry Education and Training Centre (2010); Timber Legality of Verification – Forestry Education and Training Cetre (2010); RSPO Lead Auditor Course – Pro Forest & Wild Asia (2011); SCCS RSPO by David Ogg Consulting (September 2012). Working experience: Experienced as Junior Consultant at PT Surveyor Indonesia (2002 s/d 2010), assesor for SFM –mandatory (PHPL & PHTL), assessor for industry performance assessment (IPHHK)-mandatory, auditor for Timber Legality of Verfication and CoC, auditor for SMK3, auditor for QMS and EMS and auditor for ISPO, RSPO & SCCS at TUV Rheinland Indonesia. Education : Bachelors Degree in Forestry - Bogor Agriculture Institute. Indonesia, (1990 to 1995). Trainings attended : ISO 9001:2008 lead auditor course – PT TUV Rheinland Indonesia (2014, certified); Compliance in The TUV Rheinland Group/learning course – PT TUV Rheinland Indonesia (2014, certified), FSC/PEFC Chain of Custody Standard training – PT TUV Rheinland Indonesia (2013, certified), Indonesian Sustainable Palm Oil / ISPO training – ISPO Commission (2013, certified), Upgrading Auditor Training for Natural Forest Management Certification Sustainable Production - Center for Forestry Education and Training, Ministry of Forestry of Indonesia (2010, certified), Competency Exam Passed as Auditor in Production Aspects – Indonesian Ecolabelling Institute / LEI (2010, certified), Upgrading Auditor Training for Timber Legality Verification - Center for Forestry Education and Training, Ministry of Forestry of Indonesia (2010, certified), Auditor Training for Verification of Wood Industry and Wood Products - Cooperation Development Research Center of Ministry of Forestry with PT. Sucofindo (2005, certified), Natural Forest Management and Sustainable Production Certification training - Indonesian Ecolabelling Institute / LEI (1998, certified). Working experience : Staff Division Forestry PT Aji Buana Asri, Jakarta (1995 – 1997), Executive Secretaris PT Pro Natres Development, Bogor (1997 – 1998), Planning Superintendent and Analyse the board of directors office PT Dalek Hutani Esa – Natural Forest Concession Company, Jakarta (1999 – 2003), Quality Control PT. Sucofindo (Persero) in Project Exporter Verification Enlisted by an Industrial Product of forestry and Project Monitoring Performance of Wood Suplier and Wood Buyer between Island in Indonesia (2005 – 2006 and 2007), Forestry Assistant at Consultant PT. Hatfield Indonesia to QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 7 of 21 Name Position Qualifications / Experience support project “ Forestry Stakeholder Mapping and Database Assessment “, project from IFC (International Finance Corporation, World Bank Group) Advisory Services Indonesia (2009), Assesor for SFM (2010 – 2014) : Mandatory (PHPL & PHTL), Assessor for industry performance assessment (IPHHK), Auditor for Timber Legality of Verfication and CoC, Auditor for ISPO & SCCS at PT TUV Rheinland Indonesia. 2.3 Assessment Methodology & Agenda The supply chain certification assessment was conducted on October 9, 2014 as per the assessment program below. The assessment was carried out in accordance PT TUV Rheinland Indonesia’s RSPO audit procedure as well as the RSPO Supply Chain Certification document. An on-site assessment was conducted and the assessment team carried out field and document assessments of compliance to RSPO Supply Chain Certification System requirements. The company proposed the correction and corrective action for all identified non conformities raised to the certification body 15 days after the closing meeting. Verification of closure of non-conformances was conducted through document checked 1 (one) months after the closing meeting of the main assessment. The certification assessment agenda is as explained below. Main Assessment Agenda Date Oct 9, 2014 Location/ Main sites Plant office & Plant Tj port Priok Main activities • Opening meeting • Company profile • Verification of document & field : − Some procedure are related of SCCS such as procedure of the handling of document & data, procedure of correction & corrective action, procedure of base material receipt, procedure of the dispatch of product and finished goods, procedure of non-conformities product, procedure of the selection & evaluation supplier/vendor, etc. − List of suppliers and buyers − A set of base material receipt records (since unloading in port until plant/mill) − A set of dispatch of product or finished goods record (since − Matrix of training year 2014 − Handling and documentation incoming material and dispatch product QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 8 of 21 3.0 ASSESSMENT FINDINGS 3.1 Description of Supply Chain Management System The following is a description of the findings pertaining to the company’s supply chain management system according to the RSPO SCCS requirements, including status of compliance of the company and their outsourced third parties to RSPO SCCS requirements: Section 1: General Chain of Custody System Requirements for the Supply Chain 1. Applicability of the General Chain of Custody System Requirements for the supply chain Findings: PT Wilmar Cahaya Indonesia Tbk (WICA) is a member of Wilmar International Limited. It is strategically located at Jababeka Industry Area II - Cikarang, Indonesia. It is a factory/plant/facility to fractionation and refinery palm kernel oil. Management of PT Wilmar Cahaya Indonesia Tbk has commitment to implement RSPO SCCS. The company’s supply chain management system integrated with the implementation of quality management system (ISO 9001:2008), environmental management system (ISO 14001:2004), OHSAS (ISO 18001:2007), food safety (ISO 22000:2010), Halal certificate and Halal assurance system (Sistem Jaminan Halal) Certification. Following the nature of company’s material purchased availability for production facilities. PT WICA Tbk management decided to implement Mass Balance (MB) and Segregation (SG) system supply chain model (Module B and C). During certification audit the company has demonstrate their implementation to SCCS system and relevant requirement through the simulation process. Based on notary deed no. 6 dated on May 10, 2013, WICA’s shareholders are Tradesound Investments Limited is a company belong to Wilmar International Limited. Wilmar International Limited is RSPO member with membership number 2-0017-05-000-00. Compliance status : Full Compliance 2. Documented procedures Findings: The company has written procedures to ensure implementation of all SCCS elements/requirements. The procedure were updated and convering all activities in PT WICA Tbk. The list of procedure regarding SCCS implementation conist of : 1. Procedure of receive/incoming raw material (QP/WICA-06-008 rev.2) 2. Procedure of dispatch product/finished goofs (QP/WICA-06-010 rev.2) 3. Procedure of training and develop employee (QP/WICA-06-020 rev.4) 4. Procedure of identification & traceability (QP/WICA-06-024 rev.2) 5. Procedure of oil transfer (QP/WICA-06-026 rev.1) 6. Procedure of unloading from vessel (SOP/WICA-LOG-06-003 rev.3) 7. Procedure of loading to vessel (SOP/WICA-LOG-06-004 rev.3) 8. Procedure of the administration of receive raw material (SOP/WICA-LOG-06-005 rev.5) 9. Procedure of the administration of oil dispatch (SOP/WICA-LOG-06-006 rev.4) 10. Procedure of mass balance and traceability for RSPO Procedure (QP/WICA-14-069 rev.0) 11. Procedure of handling non-conformity material/documents in RSPO SCCS (QP/WICA-14-070 rev.1) QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 9 of 21 12. Procedure of RSPO (QP/WICA-14-068 rev.0) The company has records and reports for all activities relate of SCCS implement example storage tank daily report, discharging report, unloading report, receive raw material report, delivery note from Tanjung Priok port to Cikarang plant, weighbridge ticket for receive or dispatch material, the request of oil transfer note, shipment loading detail, bill of lading, manifest, etc. All records and reports has not been marking SC model because this is main assessment, the implementation of RSPO SCCS system will be conducted after SCCS certificate awarded. Specifically for Mass Balance (MB) and Segregation (SG) Model will be implemented, auditee has procedures of handling of raw material and product with both of SCCS model form incoming until dispatch i.e as procedure of RSPO (QP/WICA-14-068 rev.0). The name of the person having overal responsibility for and authority for the implementation of all RSPO SCCS requirement, ISO 9001:2008, ISO 22000:2005/FSSC 2200:2010, ISO 14001:2004 and ISO 18001:2007 has bees assigned, i.e. Mrs. Neny Kurniawati was appointed as Management Representative (MR) according to decree letter of general manager no.148/SK/WICA/VIII/2014. During the audit time, MR has good knowledge and able to demonstrate awareness of the facility’s procedures and process. Compliance status : Full Compliance 3. Purchasing and goods in Findings: The list supplier and volume of incoming material period of 2013 and 2014 year (until September) has informed on Table 4. Raw material supplier is PT WICA-Pontianak and PT SAP-Palembang for PKO product with quantity amount of 38,465.03 tonnes. Currently, all incoming material from both of suppliers has categorized as non-certified material because both of suppliers has not RSPO certificate. In the RSPO procedure (QP/WICA-14-068 rev.0) sub section 5.1 the purchase of CSPKO explain that trading department in head office will confirming to suppliers regarding purchase transaction by purchase order with completing of SCC model. Logistic department responsible to ensuring and informing to unloading officer in port of Tanjung Priok regarding incoming material as certified or non-certified. Based on the procedure of unloading material from vessel (SOP/WICA-LOG-06-003) that unloading officer will checking of seal in vessel, conduct of sounding, supervise of unloading material to truck, install of seal in truck and compilation of unloading document. In the administration of incoming raw material procedure (SOP/WICALOG-06-005 rev.5) that Weigh Brigde operator must checking delivery note from port whether in accordance with the received information (name/type of oil, quantity, supplier name, customer name, note or description or the stamp of RSPO SG/MB) but inside procedure of the administration of incoming raw material does not include responsibility from the unloading officer to provide information about the category of product (certified or non-certified) and identification of supply chain model on delivery note at the port. This is raised as non-conformities (NCR No.2014-01 of 02). The auditee also has mechanism to ensure validity of the facilities certificate (procedure of handling nonconformance material/documents in RSPO SCCS (QP/WICA-14-070 rev.1) sub section 4.3) which was listed on supplier list (LS/WICA-QC-14-001A) every 6 months via the list of RSPO Supply Chain Certified facilities on the RSPO website (www.rspo.org). The auditee has procedure of handling non- conformance product/document (QP/WICA-14-070 rev.1). The mechanism has covered to take appropriate steps when the supply chain certification of a supplier is found to be invalid, mismatches of quantity, mismatches of quality, the RSPO SCCS certificate was owned by supplier has been expired and the receipt document was not stamped RSPO SCC model. The procedure of handling non-conformity material/document in RSPO SCCS sub section 4.4.1 has explaine that CSPKO will be declared as non certified if the certificate found expired, however this claimed still not include for certified product with segregation (SG) model. This is raised as non-conformity. (NCR No.2014-02 of 02). Compliance status : Non Compliance QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 10 of 21 NCR No.2014-01 of 02 In the procedure of the administration of incoming raw material does not include responsibility from the unloading officer to provide information about the category of product (certified or non-certified) and identification of supply chain model on delivery note at the port of tanjung priok. NCR No.2014-02 of 02 In the procedure of handling non-conformity material/document in RSPO SCCS (QP/WICA-14-070 rev.1) does not include step/mechanism of handling non-conformity material/document in RSPO SCCS with segregation (SG) SC model. 4. Outsourcing activities Findings: The company outsources some activities such as unloading material from the vessel and transports the material from Tanjung Priok port to Cikarang mill and loading the product from the facoty to the vessel. There is no material storage in the port due to the material from the vessel is directly transported to the Cikarang facilty. The company assigned personnel in Tanjung Priok who has responsibility to check road tanker condition before transport the material to Cikarang facility. He also has responsibility for material weighing and submits the report to Cikarang factory. Facilities does not release or relinquish the legal ownership of all material inputs included in the process that are outsourced where auditee have fully control for all activity. Conditions legal ownership by the facilities is recorded in the MoU and the statement letter was made by the Transporter (transportation service). Inside the MoU and statement letter has included the scope of outsourcing activities and the certification bodies have unrestricted access to the outsourcing contractor/company (their respective operation, system and all information). Facility has a list of transporter to transport material from Tanjung Priok port, there are 6 transporters to and 7 transporter to transport the product from Cikarang factory to Tanjung Priok Port, as stated on i.e.: document: LT/WICA-LOG-13-001 Rev 2. Raw Material’s Transporter : 1. PT Maju Arta Sampurna / Angkutan 168 2. PT Sinar Citra Lestari 3. PT Syafaat Transmandiri 4. PT Kusuma Berkat Abadi 5. PT Mandiri Trans Abadi 6. PT Mitra Karya Manunggal Trans. Product’s Transporter : 1. CV KH Transport 2. PT Rajawali Dwi Putra Indonesia 3. PT Surya Mitra Tirta Kencana 4. PT Sarana Berkat Anugerah Transport 5. PT Bumi Merak Transportasi 6. PT Galuh Protank Logistiks 7. Ueno Container Logistiks PTE LTD Facility has a procedure for handling changes of names and contact details of transporters that are used in the production process or RSPO certified material. There is procedure is for handling of Non-Confirmity Materials i.e. QP/WICA-14-07 Rev. 0. The procedure explains about records of non conformace material and its handling process. Compliance status : Full Compliance QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 11 of 21 5. Sales and goods out Findings : The auditee has dispatch product mechanism as determined on procedure of the administration of dispacth liquid product (SOP/WICA-LOG-06-006 rev.4). Logistic section received product delivery schedule and copy of sales order from marketing/PPIC/customer as basic information to make Shipping Instruction (F/WICA-PPIC-06-005) for shipping agent, there is specific statement must be attached for RSPO product with selected supply chain model SG or MB. After product loading finished, the weigh bridge operator make delivery note and weighbridge ticket with information about selected supply chain model for certified product. Information for product sold for period 2013 and 2014 was stated on Table 3 above. There are some documents for product delivery, i.e: delivery note and weighbridge ticket for road tanker while for vesell are delivery note, weighbridge ticket, bill of lading and product manifest. Information stated on delivery document including the name and address of the buyer, the name and address of the seller, the loading or delivery date, the date on which the document were issued, description of product, the quantity of the products delivered, any related transport documentation. The company will put information about selected Supply chain model and certification reference number after they get SCCS certificate. Sampel of delivery document for product dispact using road tanker, such as : • Delivery note no. : 8305108902/3, • Weighbridge ticket no. : CACR0001229, • SO no. : 8301100641, • PO no. : 6380000324, • The name and address of the buyer : PT Lautan Natural Krimerindo, Jl. Mojosari-Pacet KM 4, Mojokerto – East Java, • The name and address of the seller : PT Wilmar Cahaya Indonesia Tbk, Kawasan Industri Jababeka Tahap II, Jl Industri Selatan III Block GG I, Cikarang – Bekasi, West Java, • The loading or delivery date : October 6, 2014 • The date on which the document were issued : October 6, 2014 • Description of the product : RHPK Olein • Quantity : 22,650 kg • Any related transport documentation : L 9498 UR (truck) While sample of delivery document for dispatch product using vessel, such as : Plant to port • Delivery note : 8305107409/57 (the one of trips) • Weighbridge ticket no. : CACR0000709 (the one of trips) • SO no. : 8301102177, • PO no. : 810157492, Port to buyer • Bill of Lading : No.004/HMH/TPK/IX/14 • Manifest • The name and address of the buyer : PT Wilmar Nabati Indonesia, Gresik District • The name and address of the seller : PT Wilmar Cahaya Indonesia Tbk, Cikarang Sub District, Bekasi District • The loading or delivery date : September 7, 2014 • The date on which the document were issued : September 7, 2014 • Description of the product : RPKOL • Quantity : 1,467.04 ton • Any related transport documentation : MT Kyodo (vessel) Compliance status : Full Compliance 6. Registration Findings : QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 12 of 21 PT Wilmar Cahaya Indonesia Tbk process palm kernel oil becomes its derivatives product such as edible oil. The company has been register to RSPO IT system (e-trace) for certified product transaction and under trading division in Singapore. However the transaction system will be implemented after the company get certificate. This is requirement not applicable for this time. Compliance status: Not Applicable for this time 7. Training Findings: The facility has the procedures of Training and Development for the employee, as stated on document number: QP/WICA-06-020 Rev 5 effective dated March 1, 2014. The procedure stated that the training program was developed based on training need that submitted from each departement to Personel and General Affair departement (PGA) , and PGA arrange Matrix Annual training (F/WICA-PGA-006-011), the matrix contains about : types and classification of the training, number of participants (target group) and training schedule for 1 (one) year. The facility has been compiled Matrix Training for the year of 2014 using document form number : F/WICAPGA-06-011 Rev 3 made by the Head Department approved by the Head Unit, among others is RSPO SCCS (Supply Chain Certification Systems) Training will be conducted internally on November 2014. Compliance status : Full Compliance 8. Claims Findings : The company has an SOP for making claims certified product according RSPO communication and claims however company not claim the product directly, due company only produce intermediate product not finsihed good consumer product. Compliance status : Not Applicable Section 2: Modular Requirements: Module B – Segregation B.1. Processing Findings : Based on procedure of RSPO (QP/WICA-14-068 rev.0) that auditee will use the same supply chain model as its supplier. Logistic department will ensuring and verify that material with SG status will be use to process SG product as stated on document from marketing departement. Moreover, the company provide a procedure regarding declassification/downgrading of raw material status. The auditee has provided procedure that the RSPO certified palm product is kept segregated from noncertified material since material transported and storage, the PPIC section has responsibility to ensure this condition along the production process while for transport and storage is responsible of logistic division). To ensure that certified product with claim SG will not contaminated with non certified SG product. Compliance status: Full Complaince B.2. Record keeping QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 13 of 21 Findings : The company has established a mechanism to control and maintenance of document and data used in production process as stated on the document and records control procedure, the retention time for all records and reports for certified material and product has been defined for at least for five (5) years. The storage and maintainance of documents is the responsibility of the respective departments. According to procedure, company will clearly indicate the supply chain model used with trade names in relevant documents (in purchase order) from trading department in Head Office. Moreover, in procedure of identification & traceability has explain that PPIC daily report is a document that is used to ensure trace back to only certified segregated material. Compliance status : Full Compliance Section 3: Modular Requirements: Module C – Mass Balance C.1. Processing Findings : Based on procedure of RSPO (QP/WICA-14-068 rev.0) the company will use the same supply chain model following the material supplied from supplier. Logistic department ensure and verify that material with SG or MB are used for processing a product with MB status appropriate of request form marketing in Head Office. Moreover, the auditee has provided a procedure regarding declassification/downgrading of raw material status. The facility has provided the storage tank dedicated to MB product but if the storage tank will be used for SG product so that the facility shall be cleaning before used. Compliance status: Full Compliance C.2. Record keeping Findings : The company has established a mechanism to control and maintenance of document and data used in production process as stated on the document and records control procedure, the retention time for all records and reports for certified material and product has been defined for at least for five (5) years. The storage and maintainance of documents is the responsibility of the respective departments. According to procedure, company will clearly indicate the supply chain model used with trade names in relevant documents (in purchase order) from trading department in Head Office. Moreover, in procedure of identification & traceability has explain that PPIC daily report is a document that is used to ensure trace back to only certified segregated material. . Compliance status : Full Compliance C.3. Mass balancing system Findings : Auditee has establish a mechanism to ensure that the quantity of physical RSPO mass balance material inputs and output on a real time basis at mass balance and traceability for RSPO procedure (QP/WICA-14069 rev.0). All volumes of palm oil that are delivered are deducted from the material accounting system ac- QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 14 of 21 cording to actual daily conversion ratios. Officer from PPIC section has been assign to monitor daily report regarding internal material accounting system will be complies with the RSPO requirement such as can only deliver Mass Balance sales from a positive stock. The implementation of certified product accounting system will be started after auditee getting certified approval from RSPO CB. Compliance status: Full Compliance 3.2 Identified Non-conformances against RSPO SCCS Requirements, Corrective Actions Taken and Auditors Conclusions SCCS Non-conformance 2014-01 of 02 : In the procedure of the administration of incoming raw material does not include responsibility from the unloading officer to provide information about the category of product (certified or non-certified) and identification of supply chain model on delivery note at Tanjung Priok Port. Correction : • Revision of procedure no. SOP/WICA-LOG-06-003 and quality plan recipt and dispatch • Revision of statement letter from PT Sari Agrotama Persada regarding job description and responsible for handling material own PT WICA Tbk which have been agreed by both party. Corrective Action : The coordination and submit the latest procedures with PT Sari Agrotama Persada regarding handling material and product in port. Auditor Conclusions : Closed Date of closure : October 30, 2014 Evidence of correction : The auditee has provided revision of the procedure for loading product to vessel (SOP/WICA-LOG-06-004 rev.4) and unloading material from vessel (SOP/WICA-LOG-06-003 rev.4). Additional information in revision of the procedure of loading product to vessel (SOP/WICA-LOG-06-004 rev.4) and unloading material from vessel (SOP/WICA-LOG-06-003 rev.4) are field operator will provide information about the category of product (certified or non-certified) and identification of supply chain model on weighbridge ticket (loading activities) or delivery note (unloading activities). Moreover, auditee has provided statement letter from PT Sari Agrotama Persada where their contents conists of : • Field officer will provide information about the category of product (certified or non-certified) and identification of supply chain model on delivery note (unloading of raw material) where based on information on Bill of Lading & manifest and information from trading department in head office. • Field officer will provide information about the category of product (certified or non-certified) and identification of supply chain model on weighbridge ticket (loading of product) where based on delivery note from PT WICA Tbk. • To ensure that special material with RSPO SG status not contaminated with other material during unloading to truck and loading to vessel. • Coordinating with logistic department from PT WICA Tbk QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 15 of 21 SCCS Non-conformance 2014-02 of 02: In the procedure of handling non-conformity material/document in RSPO SCCS (QP/WICA-14-070 rev.1) does not include step/mechanism of handling non-conformity material/document in RSPO SCCS with segregation (SG) SC model Correction : Revision of handling material/document procedure (QP/WICA-14-070) Corrective Action : Ensure all procedure compliance with SCCS requirement and appropriate with real condition in field Auditor Conclusions : Closed Date of closure : October 30, 2014 The company has provided revision of the procedure of handling non conformity material/document in RSPO SCCS (QP/WICA-LOG-14-070 rev.1). Handling of material with segregation supply chain model if supplier’s RSPO certificate not valid is material will be unloaded with a change in status to a non-certified in accordance with the agreement of both parties. 3.3 Conclusion and Recommendation for RSPO Supply Chain Certification The audit team has confirmed through the audit process that PT Wilmar Cahaya Indonesia Tbk has established and maintains an effective system to ensure compliance with the RSPO Supply Chain Certification requirements (dated November 2011). PT TUV Rheinland Indonesia recommends that PT Wilmar Cahaya Indonesia Tbk be approved for certification of compliance to the RSPO Supply Chain Certification requirements. QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 16 of 21 4.0 CERTIFIED ORGANISATION’S ACKNOWLEDGEMENT OF INTERNAL RESPONSIBILITY 4.1 Date of Next Surveillance Visit The next surveillance visit is planned for October 2015 4.2 Acknowledgements of Internal Responsibility and Formal Sign-Off by Client It is acknowledged that the assessment visit was carried out as described in this report and we accept the assessment findings and report content. Signed on behalf of PT Wilmar Cahaya Indonesia Tbk …………………………………………. Neni Kurniawati Management Representative Date : December 8, 2014 Signed on behalf of PT TUV Rheinland Indonesia …………………………………………. Hendra Fachrurozy Lead Auditor Date : December 8, 2014 QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 17 of 21 APPENDICES Appendix 1: Details of Supply Chain Certification Certificate QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 18 of 21 QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 19 of 21 Appendix 2: List of Abbreviations CBR CBS CPO HKL LOG MB PKO QP RBD PKOL / RKL RBD PKST / RKS RHKL RHKS RBD-PKO / RKO SAP SCCS SG SJH WICA Cocoa Butter Replacer Cocoa Butter Substituse Crude Palm Oil Hydrogenated Palm Kernel Olein Logistic Mass Balance Palm Kernel Oil Quality Procedure Refined Bleached Deodorized Pal Kernel Olein / Refined Palm Kernel Olein Refined Bleached Deodorized Pal Kernel Stearin / Refined Palm Kernel Stearin Refine Hydrogenated Palm Kernel Olein Refine Hydrogenated Palm Kernel Stearin Refined Bleached Deodorized Pal Kernel Oil / Refine Palm Kernel Oil PT Sari Agrotama Persada Supply Chain Certification System Segregation Sistem Jaminan Halal (Halal Assurance Halal) PT Wilmar Cahaya Indonesia Tbk Appendix 3: Observations and Opportunities for Improvement No. 1 Observations / Opportunities for Improvement The column of checked and approved on weighbridge ticket from PT Sari Agrotama Persada should fillI with signature and name of the relevant officer. QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 20 of 21 Appendix 4: Supply Chain Certification Audit Closing Meeting Summary QMF: RSPO-007c-13 rev.2 RSPO Certification Assessment Report PT Wilmar Cahaya Indonesia Tbk – Cikarang, West Java Page 21 of 21 Appendix 5 : List of supplier and buyer Certificate No. Certificate Certificate Validation Name of Supplier Address Product PT Wilmar Cahaya Indonesia – Pontianak Jl. Khatulistiwa KM.4.3, Batulayang, Pontianak, West Kalimantan Province PKO - - - PT Sari Agrotama Persada – Palembang Jl. Blabak No.18, Tiga Ilir, Palembang, South Sumatera Province PKO - - - Certificate No. Address Product PT Unilever Indonesia – Surabaya PT Sinar Antjol Jl. Rungkut Industri IV/5-11, Surabaya, East Java RKO - - - Jl. Malaka II No.1-3, South Jakarta, DKI Jakarta Province RKO - - - PT Tempo Nagadi Jakarta Industrial Estate Pulogadung, Jl. Pulo Kambing Block BI 2 – E/5-8, Jatinegara, East Jakarta District, DKI Jakarta Province RKO - - - Multi Commodity International LTD Suntec Tower 3 Suite No.3526 CO8, Singapore RKO, RKL - - - PT Ayu Cemerlang Jl. Mangga Besar VI Utara No.18B, West Jakarta District, DKI Jakarta Province RKL - - - PT Wilmar Nabati Indonesia – Gresik Jl Kapten Darmo Sugondo No.56, Indro village, Kebomas Sub District, Gresik District, East Java Province RKO, RKL, HKL RSPO SCCS 185 0 2248 001 Valid until January 31, 2018 PT Lautan Krimerindo Jl. Raya Mojosari-Pacet KM.4, Pesanggrahan village, Kutorejo Sub District, Mojokerto District, East Java Province RHKL - - - PT Kievite Indonesia – Pasar Rebo Jl. Raya Bogor KM 5, Pasar Rebo, Jakarta Timur, DKI Jakarta Province RHKL - - - PT Kievite Indonesia – Salatiga Jl Merpati No.1 Salatiga District, East Java Province 50721, Indonesia RHKL IV < 1 RSPO SCCS CU-RSPO SCCS-829955 Valid until November 14, 2018 PT Gandum Kencana Jl. Moh. Toha KM 2.1, Karawaci Sub District, Tanggerang District, Banten Province RHKS - - - KIIC Lot J 2-A, Tanjungpura Sub District, Karawang District, West Java Province RHKS - - - Jl. Gandasari 79 RT 008/02, Curug Sub District, Tangerang District, Banten Province RHKS - - - PT Sayap Mas Utama Jl. Tipar Cakung Kav. F5-7, East Jakarta District, DKI Jakarta Province RKO - - - PT Royal Industries Indonesia Surya Cipta Industry Estate, Jl. Surya Utama Kav.1-4, Karawang District, West Java Province RKO - - - Naturally Natural Mas PT Freyabadi Indotama PT Pusan Manis Mulia Certificate Certificate Validation Buyer QMF: RSPO-007c-13 rev.2