Department of the Army *FORSCOM Regulation 700

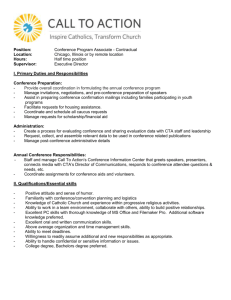

advertisement