20th European Symposium on Computer Aided Process Engineering – ESCAPE20

S. Pierucci and G. Buzzi Ferraris (Editors)

© 2010 Elsevier B.V. All rights reserved. Simulation of ethanol production from sugarcane

in Brazil: economic study of an autonomous

distillery

Marina O.S. Diasa,b, Marcelo P. Cunhaa, Charles D.F. Jesusa, Mirna I.G.

Scandiffioa, Carlos E.V. Rossella,b, Rubens Maciel Filhob, Antonio Bonomia

a

CTBE – Bioethanol Science and Technology National Laboratory, PO Box 6170 –

CEP 13083-970, Campinas – SP, Brazil, marina.dias@bioetanol.org.br

b

School of Chemical Engineering, University of Campinas, PO Box 6066 – CEP

13083-970, Campinas – SP, Brazil

Abstract

Simulation of the production of ethanol from sugarcane in an autonomous distillery was

carried out using software SuperPro Designer and electronic spreadsheet. Analysis of

the ethanol production costs was performed for different production scenarios,

considering improvements on the energy production from sugarcane bagasse and the

selling of surplus electricity. It was verified that selling of surplus electricity positively

influences the ethanol production costs.

Keywords: ethanol, simulation, sugarcane, economic evaluation.

1. Introduction

Brazil produces bioethanol from sugarcane on a large scale basis since the 1970s (Bake

et al., 2009); increase on the demand for the biofuel as a substitute or complement of

gasoline has motivated the search for more efficient means of production. As a

consequence, the evaluation of conventional ethanol production and the identification of

critical process parameters are required. Brazil and the United States, which produces

ethanol from corn, are the largest ethanol producers in the world (Balat et al., 2008);

however, net energy of ethanol production from sugarcane is more positive than that

from corn (Leite et al., 2009): sugarcane bagasse, one of the main by-products of

sugarcane processing, is used as fuel in cogeneration systems, which provide steam and

electric energy to supply the bioethanol production process. Thus, an autonomous

distillery may produce electric energy to sell to the grid, if there is a surplus produced

during cogeneration. For the past few years, growing interest on production of

electricity in ethanol production plants has been observed, which may improve revenues

and competitiveness of sugarcane ethanol.

In this work, simulations of ethanol production from sugarcane were carried out using

SuperPro Designer 7.5 (Intelligen, Inc) in order to evaluate production costs within the

industrial site. A “standard” autonomous distillery is considered, in which 500 tons of

sugarcane (TC) per hour are processed, producing 1000 m³/day of anhydrous

bioethanol, during 180 days (sugarcane harvest season). Data used to simulate the unit

operations were obtained from industrial sites and from literature.

2. Ethanol production process from sugarcane

In an autonomous distillery, all the sugarcane processed is used to provide sugars for

fermentation, from which ethanol is produced.

M.O.S. Dias et al.

The main steps required for the ethanol production process from sugarcane in an

autonomous distillery are illustrated in Fig. 1.

Figure 1. Simplified block flow diagram of the anhydrous bioethanol production process from

sugarcane in an autonomous distillery.

3. Process simulation procedure

Operating and process parameters of the autonomous distillery were obtained in the

literature and from operating industries. A “standard” plant is considered, with unit

operations typical of those found in the Brazilian bioethanol industry. 500 TC per hour

are processed for production of around 1000 m³/day of anhydrous bioethanol (99.3 wt

% ethanol).

3.1. Simulation

Firstly, a mass balance of the process was carried out using a spreadsheet, in which

usual industrial parameters (efficiency of unit operations, amount of raw materials and

yields) were employed. Then, simulation was carried out using software SuperPro

Designer 7.5 from Intelligen, Inc, considering the unit operations indicated in Fig. 1

except for the operations related to the cogeneration system. In these operations, where

steam and electric energy are produced, calculation was performed using a conventional

spreadsheet, since the simulation software does not have the procedures required to

perform its simulation at the moment. A simplified flowsheet of the simulation of

bioethanol production process is shown in Fig. 2.

Several hypothetic components (sugarcane bagasse constituents, sugarcane impurities,

etc.) were inserted into the simulator database, in order to represent the bioethanol

production process more accurately. Energy demand of unit operations that are not

available in the simulator database, such as extraction of sugars in the mills, azeotropic

distillation and adsorption onto molecular sieves (processes used on ethanol

dehydration), was obtained in the literature (Ensinas et al., 2007; Andrietta, 2009).

The main process parameters are listed in Table 1.

3.2. Dehydration processes

Two dehydration processes were considered: azeotropic distillation using cyclohexane

as entrainer, which is the most common and most energy-intensive process used in

ethanol dehydration, and adsorption onto molecular sieves, which presents the lowest

energy consumption among the commercial dehydration processes available, but

requires a larger investment.

Simulation of ethanol production from sugarcane in Brazil: economic study of an

autonomous distillery

Figure 2. Simplified flowsheet of the simulation of bioethanol production process carried out

using SuperPro Designer.

Table 1. Main parameters adopted in the simulation of the “standard” plant.

Parameter

Sugarcane crushing rate

Days of operation

Fibre on sugarcane

Sugars on sugarcane

Amount of sugarcane trash produced in the fields

Dirt removal on sugarcane cleaning

Sugar losses on sugarcane cleaning

Sugars recovery on the mills

Sugarcane bagasse water content

Recovery of sugars on juice treatment

Fermentation yield

Ethanol recovery on distillation and dehydration

Value Unit

500

180

12

14

140

90

0.8

96

50

99.5

90

99.7

TC/h

days/year

wt%

wt%

kg/TC

%

kg/TC

%

wt%

%

%

%

3.3. Cogeneration system

Conventional plants are equipped with boilers for the production of 22 bar steam, in

which sugarcane bagasse, produced in the mills, is used as fuel. The steam produced in

the boilers is used to produce electricity in steam turbines and as thermal energy for the

process, besides being used in mechanical drivers in the sugarcane preparation and juice

extraction systems.

A 90 bar cogeneration system with back pressure and condensing steam turbines for

production of steam and electric energy is considered as well, in which surplus

electricity is sold to the grid. The amount of sugarcane bagasse available for

cogeneration and the process steam demand are obtained in the simulation and used to

determine the parameters of the coproduction of heat and power (CHP) plant; as a

M.O.S. Dias et al.

result, the amount of surplus electric energy available for sale is determined. The main

parameters of the CHP system are shown in Table 2.

Table 2. Main parameters considered in the simulation of the CHP system (Dias et al., 2009;

Ensinas, 2008; Seabra, 2008).

Value

Parameter

Unit

*

22 bar – boiler thermal efficiency

75

%

90 bar – boiler thermal efficiency*

86

%

High pressure steam turbines isentropic efficiency

72

%

Intermediate pressure steam turbines isentropic efficiency

81

%

Condensation turbine isentropic efficiency

70

%

Mechanical drivers – turbine isentropic efficiency

55

%

Generator efficiency

96

%

Sugarcane bagasse LHV (50 wt% water)

7565

kJ/kg

Sugarcane trash LHV (15 wt% water)

12960 kJ/kg

Electric power demand of the distillery

12 kWh/TC

Mechanical power demand – cane preparation and juice extraction 16 kWh/TC

Electric power demand of the distillery – electric drivers

18 kWh/TC

Outlet pressure of high pressure steam turbine

22

bar

1st extraction pressure

6

bar

2nd extraction pressure

2.5

bar

Process steam pressure

2.5

bar

*

Low Heating Value (LHV) base

Besides the use of more efficient boilers (90 bar), two other process improvements were

considered: the use of electric drives for mills and other equipments, replacing the

mechanical drivers, and the use of sugarcane trash as fuel in boilers. Sugarcane trash is

composed by leaves and tops, and nowadays is burned before harvest or left in the field,

but a fraction of the trash generated may be recovered and used as a fuel in the plant. In

all the cases where excess steam is produced, it is condensed on condensing steam

turbines, increasing the amount of electricity produced. In this work, 50 % of trash is

used as fuel for the production of steam and electricity; the remaining fraction is left in

the fields in order to provide control of weeds and diseases (Hassuani et al., 2005).

4. Simulation results and discussion

Different configurations were analysed, combining the options shown in Table 3.

Table 3. Parameters considered in the studied scenarios.

Parameter

st

1 generation anhydrous ethanol production

22 bar boilers

Dehydration by azeotropic distillation

Dehydration by adsorption onto molecular sieves

Sell of surplus bagasse

90 bar boilers

Burning of surplus bagasse

Sell of surplus electricity

Electrification of drives

50 % of trash used

I II III IV

X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Simulation of ethanol production from sugarcane in Brazil: economic study of an

autonomous distillery

Case I presents the typical traditional autonomous distillery; cases II through IV present

increasing levels of technologic improvements considered in this work, which influence

the production of electricity. Simulation results for each of the studied scenarios are

displayed in Table 4.

Table 4. Simulation results for each of the studied scenarios.

I

Parameter

II

III

IV

Anhydrous ethanol production – L/t sugarcane 83.3 83.3 83.3 83.3

Surplus bagasse – kg/t sugarcane

16.6 0

0

0

Surplus electricity sold – kWh/t sugarcane

0 68.2 73.7 154.9

5. Economic evaluation and discussion

On Table 5 the basic parameters for the economic analysis are displayed.

Table 5. Basic parameters used in the economic analysis1.

Parameter

Value

25 years

2 years

US$ 16.58/t

US$ 12.21/t

10 years

34.0%

US$ 0.40/L

US$ 67.05/MWh

US$ 16.58/t

Project lifetime

Salvage value of equipment

Construction and start-up

Sugarcane price2

Trash price (15% moisture)3

Depreciation (linear)

Tax rate (income and social contributions)

Ethanol (producer price)4

Bioelectricity (producer price)3

Bagasse (producer price)5

1

Considered the exchange rate US$ 1.00 = R$ 2.088 (average of the past 12 months)

Average of the last 12 months (UDOP, 2009)

3

Seabra, 2008

4

Average of the last 12 months (CEPEA, 2009)

5

Considered equal to the sugarcane price

2

In order to evaluate ethanol production costs, equipment costs were evaluated for each

of the studied scenarios based on data provided by the industry. Firstly, economic

analysis of each of the studied scenarios was carried out using the parameters presented

in Table 5. Production costs were then calculated reducing ethanol, surplus bagasse and

electricity prices (amount paid to the producer) simultaneously, at the same proportion,

until real profits reached zero (i.e, internal rate of return per year equal to zero). Table 6

presents the investment required on equipments for each scenario and the calculated

ethanol production costs.

Table 6. Investment and ethanol production costs on each scenario.

I

Parameter

II

III

IV

6

Equipment costs – 10 US$

144 185 185 205

Ethanol production costs – US$/L 0.313 0.289 0.286 0.265

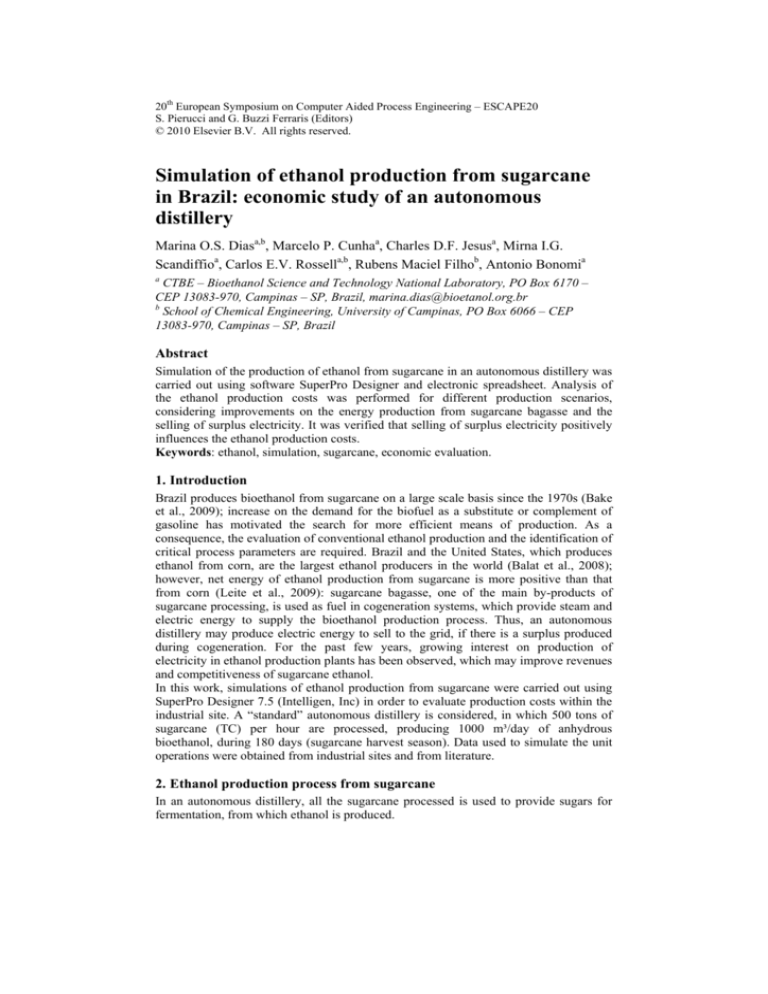

Since sugarcane costs are equivalent to roughly 60 % of the final production costs of

ethanol, a sensitivity analysis was carried out in order to evaluate sugarcane costs on the

final ethanol cost; results are presented in Fig. 3 for the four studied scenarios.

M.O.S. Dias et al.

Figure 3. Evaluation of anhydrous ethanol production costs for different sugarcane prices.

6. Conclusions

In this work simulation of a typical autonomous distillery for anhydrous bioethanol

production from sugarcane was carried out. Selling of surplus electricity (cases II

through IV) can improve the profitability of ethanol production from sugarcane, since it

leads to a reduction on ethanol production costs. The use of sugarcane trash as a fuel on

cogeneration systems can significantly reduce ethanol production costs, since large

amounts of electricity are available for sale.

7. Acknowledgements

The authors acknowledge Dedini Indústrias de Base S/A for supplying data for

investment calculations.

References

S.R. Andrietta, Optimal Industrial Fermentation, In: BIOEN Workshop on Process for ethanol

production, FAPESP, 2009. Available online at http://www.fapesp.br/eventos/2009/09/

10_bioen/Silvio_Roberto.pdf, retrieved on sept 15, 2009 (in Portuguese)

M. Balat, H. Balat, C. Öz, Prog. in En. and Comb.Sci., 34 (2008) 551-573

J. Bake, M. Junginger, A. Faaij, T. Poot, A. Walter, Biom. Bioen., 33 (2009) 644-658

CEPEA - Center for Advanced Studies on Applied Economics, 2009, Available online at

www.cepea.usp.br, retrieved on nov 15, 2009

M.O.S. Dias, A.V. Ensinas, S.A. Nebra, R. Maciel Filho, C.E.V. Rossell, M.R.W. Maciel, Chem.

Eng. Res. Des., 87 (2009) 1206-1216

A.V. Ensinas, S.A. Nebra, M.A. Lozano, L.M. Serra, En. Conv. Manag., 48 (2007) 2978–2987

A.V. Ensinas, PhD Thesis (Mechanical Engineering), School of Mechanical Engineering, State

University of Campinas (in Portuguese), 2008

R. Leite, M. Leal, L. Cortez, W. Griffin, M. Scandiffio, Energy, 34 (2009) 655-661

S.J. Hassuani, M.R.L.V. Leal, I.C. Macedo (eds.), Biomass Power Generation—Sugarcane

Bagasse and Trash. Piracicaba: PNUD-CTC, 2005

J.E.A. Seabra, PhD Thesis (Energetic Systems Planning), School of Mechanical Engineering,

State University of Campinas (in Portuguese), 2008

UDOP – Union of Biofuel Producers, Sugarcane prices, 2009. Available online at

www.udop.com.br/index.php?item=cana. Retrieved on nov 15, 2009