Nemawashi - Association for Manufacturing Excellence

advertisement

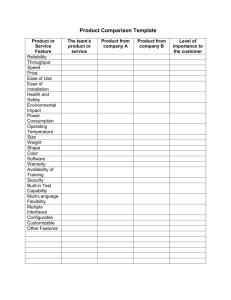

Nemawashi Mike Micklewright QualityQuest, Inc. Arlington Heights, IL mike@mikemick.com 847-401-0442 Mike Micklewright Degreed Engineer from U. of Illinois Worked at Saturn and Seaquist 15 Years Independent Lean and Quality Consultant/Trainer Keynote Presenter AME Board Member 4 ASQ Certifications Comedian, Actor, and Impersonator (representing some of my personalities) Author (“Whys Guy” in Quality Digest Magazine and “Out of Another @#^&! Crisis!”) Agenda Definition What Saturn Taught The Toyota Way Thorough Consideration in Decision Making Broadly Consider Alternative Solutions with a Set-Based Approach Where does this Fit in with the A3 Process? The Process to Achieve Nemawashi 1) 2) 3) 4) 5) 6) 7) 1) 2) 3) 4) 5) 6) 7) 8) 9) Identify the Stakeholders Determine Customer Requirements Concept Selection (part 1) How to Reach Consensus Generating Concepts Benchmarking Concept Selection (part 2) Synergize for Further Improvement Implementation Plan Definition Nemawashi Make Decisions Slowly by Consensus, Thoroughly Considering All Options; Implement Rapidly “If you’ve got a project that is supposed to be fully implemented in a year, it seems to me that the typical American company will spend about three months on planning, then they’ll begin to implement. But they’ll encounter all sorts of problems after implementation, and they’ll spend the rest of the year correcting them. However, given the same year-long project, Toyota will spend 9-10 months planning, then implement in a small way – such as with pilot production – and be fully implemented at the end of the year with virtually no remaining problems.” Alex Warren, former Senior Vice President Toyota Motor Manufacturing, Kentucky Lessons from “Celebrity Apprentice” Egos fighting for their ideas Very minimal consideration of decision criteria (wants and needs) Very minimal consideration of alternatives Whoever speaks loudest, wins No buy-in; little effort from some teammates to help team win The goal is to win, not collaborate on the best product for the customer Example: http://www.nbc.com/the-celebrityapprentice/video/clips/week-8-jesse-and-annie-debatemarketing/1088117/ What Saturn Taught In 1987, I learned about Design of Experiments (DOE). Prior to learning the details, we learned of the Total Development Process and where DOE fit in. The following 6 slides is what I learned and then taught for many years. Not all Saturn employees learned this The Phases in the Total Development Process are: I. Customer Needs Identification II. Competitive Benchmarking Nemawashi III. Concept Selection IV. Optimization V. Build, Test & Fix (2 iterations) VI. Pilot VII. Start Production DOE is used most effectively in the Optimization Phase. Total Development Process…The First Steps Strategic Decision Making has become increasingly more important in today’s business world of extreme global competition. Decisions made today on your company’s products and/or services will affect your business and its position amongst the world’s leaders for many years to come. Two strategic quality tools, Competitive Benchmarking and Concept Selection, are combined into a comprehensive model to guide your company into making an effective decisions. The first tool, Competitive Benchmarking, is fast becoming the business buzzword of the 90s. When used in conjunction with Design of Experiments, it is extremely effective in the development of new products. Perfected by Xerox in the early 80s, Benchmarking was used to gain back a dwindling market share. Yet Benchmarking is not an end in itself; rather it is a tool used in making key company decisions based on the practices of world leaders. Needless to say, the greatest Benchmarkers the world has seen were the Japanese as they studied, learned, analyzed, and perfected American Business and Manufacturing practices. Total Development Process (continued) Dr. Stuart Pugh developed the Concept Selection method of objectively analyzing different alternatives based on the needs of the customer. Concept Selection can be used to piggyback off of what was learned during the Benchmarking phase, and provides a systematic method of evaluating the Concepts generated and determining which is best for your particular application. After the concept has been selected, your team can enter the Optimization Phase by designing experiments using the Taguchi Method. Benchmarking and Concept Selection are the tools that can be used to fulfill the principle of Nemawashi. Years later, I used the following two slides to teach people about the required process of Advanced Product Quality Planning, or APQP, used in the American Automotive Industry. Some knew the way; their companies just could not implement Reduce Development Time RE-TEST DAYS TO MARKET 700 RE-DESIGN 600 500 RE-TEST 400 RE-DESIGN 300 RE-TEST 200 RE-DESIGN 100 TEST DESIGN 0 TRADITIONAL METHODS APQP PROCESS CONCEPT DEVELOPMENT And one reason why it is so important to consider many alternatives early up front before settling on one idea early, is …. The Quality Lever Product Engineering Mfg. Process Engineering Mfg./ Assy Operations Customer Takes Possession-Loss of Control For Manufacturer Customer Service 100:1 10:1 1:1 ½:1 $1 Of Net Improvement The Toyota Way by Jeffrey Liker • The Toyota Way is based on 14 Principles, which are further categorized by what have become known as the 4P’s • • • • Philosophy Process People and Partners Problem Solving The Toyota Way – Philosophy Principle 1: Base your management decisions on a long-term philosophy, even at the expense of short-term financial goals Dr. W. Edwards Deming gave us his first principle: “Create constancy of purpose towards improvement of product and service, with the aim to become competitive, stay in business, and to provide jobs.” There are strong relationships between all of Deming’s 14 Points and all 14 Principles of The Toyota Way. The Toyota Way – Process 2. Create continuous process flow to bring problems to the surface 3. Use “pull’ systems to avoid overproduction 4. Level out the workload (Heijunka) 5. Build a culture of stopping to fix problems, to get quality right the first time 6. Standardized tasks are the foundation of continuous improvement and employee empowerment 7. Use visual controls so no problems are hidden 8. Use only reliable, thoroughly tested technology that serves your people and processes The Toyota Way – People and Partners 9. Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others 10. Develop exceptional people and teams who follow your company’s philosophy 11. Respect your extended network of partners and suppliers by challenging them and helping them improve The Toyota Way Problem Solving 12. Go and see for yourself to thoroughly understand the situation (genchi genbutsu) 13. Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly 14. Become a learning organization through relentless reflection (Hansei) and continuous improvement (Kaizen) Principle 13: Problem Solving (Continuous Improvement and Learning) People and Partners (Respect, Challenge and Grow Them) Process (Eliminate Waste) Philosophy (Long Term Thinking) Make Decisions Slowly by Consensus, Thoroughly Considering All Options; Implement Rapidly The Toyota Way Preeminent analyst of strategy and tactics Nothing is assumed. Everything is verified. The goal is getting it right! How you arrive at a decision is just as important as the quality of the decision It is worse to make a decision that works out well, by chance, using a shortcut process, than to make a bad decision using a good process!! Thorough Consideration in Decision Making Major Elements: 1. 2. 3. 4. 5. Finding out what is really going on, including genchi genbutsu (Creating a Lean Culture) Understanding the underlying causes that explain surface appearances – asking “Why” five times (Root Cause Analysis) Broadly considering alternative solutions and developing a detailed rationale for the preferred solution (This Class) Building consensus within the team, including Toyota employees and outside partners (This class) Using very efficient communication vehicles to do one through four, preferably one side of a sheet of paper (A3) Broadly Consider Alternative Solutions with a Set-Based Approach Set – Based Approach Think in terms of sets of alternative approaches Think concurrently of the design of the product and the manufacturing system “Set-based concurrent engineering” In Saturn’s Engine Coolant Container the long-run, this product development process is faster than the typical “point based approach” Broadly Consider Alternative Solutions with a Set-Based Approach A Toyota engineer might attack a problem with relish by (could be a tough Freshman project): - carefully identifying the cause of the problem, - taking care to do a thorough five-why analysis, - coming up with a brilliant solution - and detailing the solution to show to his/her mentor. Broadly Consider Alternative Solutions with a Set-Based Approach Instead of evaluating the idea on its merits and congratulating the engineer, the mentor asks, - “What other alternatives have you considered?” - “How does this solution compare with those alternatives?” The engineer is stopped dead in his tracks, as he was convinced he had the best approach. Broadly Consider Alternative Solutions with a Set-Based Approach These are the questions a leader asks and support leadership qualities including: Being an active coach Insisting on excellence and holding your people accountable A leader’s job is to ensure execution Execution is: A systematic process of rigorously discussing the how(s) and what(s), questioning, tenaciously following through, and assuring accountability Bossidy and Charan Execution, The Art of Getting Things Done Broadly Consider Alternative Solutions with a Set-Based Approach Once again, it’s the process that’s most important, not the results. In other words, if the process of making a decision (product) is a good, thorough process, then the mentor is more confident in the decision (product). If the mentor only evaluated the decision (product), this is no different than relying on final inspection or running a company based on monthly review of results. Evaluating only the decision, final inspection, and monthly review of results are all not effective. Broadly Consider Alternative Solutions with a Set-Based Approach Examples of set-based thinking In developing the new suspension needed for the Prius, the Chief Engineer decided to hold a competition. Instead of using trial and error and testing one suspension alternative at a time, the competition led to over 20 different suspensions tested simultaneously. There were many hybrid engine technologies to chose from. The team began with 80 different hybrid types and systematically eliminated engines that did not meet the requirements, narrowing it down to 10 types. The team carefully considered the merits of each of these and then selected the best four. Each of these four types was then evaluated carefully through computer simulation. Based on this, they were confident in the one alternative selected. Broadly Consider Alternative Solutions with a Set-Based Approach The development of the Prius: Extreme time pressure The Chief Engineer could have asked for opinions up front on the best choice and then refined it through iteration However, The iterative approach, or “point-based” approach might have completely missed a much better alternative Part of spending 80% of time planning is considering a broad range of alternatives before deciding on one Broadly Consider Alternative Solutions with a Set-Based Approach One of the hardest and most important lessons to teach young engineers: Delay decisions until they have considered a broad range of alternatives One of the advantages of getting many different opinions from many different people is that many alternatives are brought to light that can be systematically evaluated “The best designers eliminate almost all problems they discover in the test process before they finalize a design (Seeing David in the Stone) Broadly Consider Alternative Solutions with a Set-Based Approach The author has used this process for selecting: Suppliers* Employees and Internal Auditors Process Layouts Material Flows Equipment Forklift Platform Designs Sunroof Design Engine Coolant Bottle Design Product Design Systems Solution (to RCA) Computer Vehicle and housing Broadly Consider Alternative Solutions with a Set-Based Approach * Dr. Deming taught us with his 4th Principle: “End the practice of awarding business on the basis of price tag. Instead minimize total cost. Move towards a single supplier for any one item, on a long term relationship of loyalty and trust.” Where does this fit in with the A3 Process? The most time-consuming and difficult way to understand complex ideas is to have to decipher a lengthy report filled with technical descriptions, business jargon, and tables of data. The visual approach is more efficient “a picture is worth a thousand words” People are visually oriented Communicate with as few words as possible and with visual aids Toyota’s method of communication is the A3 report All necessary information to make a complex decision is presented on one 11” x 17” piece of paper Where does this fit in with the A3 Process? A3 – the process by which a company identifies, frames, and then acts on problems and challenges at all levels – perhaps the key to its entire system of developing talent and continually deepening its knowledge and capabilities Nemawashi should be a part of A3. Nemawashi should be a part of your Corrective/Preventive Action Procedure in your ISO 9001 compliant QMS. Where does this fit in with the A3 Process? Questioning, coaching, and teaching take precedence over commanding and controlling – this is leadership! It is why these types of questions are asked: “What other alternatives have you considered?” “How does this solution compare with those alternatives?” This is where it fits in on the form (which again, is one small part of the overall A3 process) It occurs after Root Cause Analysis (RCA) This class does not cover the extremely important process of RCA Where does this fit in with the A3 Process? The more important part of the A3 process is the leading, questioning, coaching, teaching, and mentoring process that occurs. Dr. Deming’s Principle # 7: “Institute leadership. The aim of leadership should be to help people and machines and gadgets to do a better job Dr. Deming’s Principle # 13: “Institute a vigorous program of education and self-improvement” The Process to Achieve Nemawashi 1) 2) 3) 4) 5) 6) 7) 8) 9) Identify the Stakeholders Determine Customer Requirements Concept Selection (part 1) How to Reach Consensus Generating Concepts Benchmarking Concept Selection (part 2) Synergize for Further Improvement Implementation Plan “Be flexible in style, and unwavering like a rock, in principle” Thomas Jefferson 1) Identify the Stakeholders Within a company, everyone is supposed to be on the same team There is no reason to act in an adversarial way Yet, the most common problem in large corporations is the “silos phenomenon” Many different groups (departments) care more about meeting their own objectives than about the company’s success These groups (departments) seem to act as though they want their particular department or project to get all the resources – they want to win at all costs May include “lean” groups 1) Identify the Stakeholders Dr. Deming taught us his Principle #9: “Break down barriers between departments. People in research, design, sales, and production must work as a team, to foresee problems of production and in use that may be encountered with the product or service.” 1) Identify the Stakeholders At Toyota, the process used to gain consensus from the community is used every day to get input, involvement and agreement from a broad cross-section of the organization. 1) Identify the Stakeholders The preferred approach to decision making at Toyota is group consensus, but with management approval Management reserves the right to seek group input and then make a decision and announce it. This is done only if the group is struggling to get consensus and management must step in if there is urgent need for a quick decision The philosophy is to seek the maximum involvement appropriate for each situation 1) Identify the Stakeholders 1) Identify the Stakeholders Going through a thorough information gathering and analysis in decision making: Uncovers all the facts that, if not considered, could lead to a great deal of pain and backtracking Execution tends to be flawless Gets all the parties on board and supporting the decision Resistance is worked out before implementing anything Achieves a great deal of learning up front before anything is even implemented 1) Identify the Stakeholders “For some decisions, I may think I already know the answer and do not need input from others. There may be a department that is not directly involved and I think they probably do not have much to contribute. I may in fact find the right answers on my own, but I will have a hard time presenting it because the group I skipped will challenge my recommendations and ask why I did not consider this and that and the presentation will become a debate. But through Nemawashi they will agree with the presentation because they have already agreed with it. So I will go and talk to that department in advance anyway and generally I am pleasantly surprised because I get new information.” Andy Lund, Program Manager, 2004 Toyota Sienna 1) Identify the Stakeholders The team of individuals who are affected by the decision must be assembled Many people give their input and this generates consensus If suppliers or other parties could be affected by a decision, their involvement is required as well By the time the formal proposal comes up for high-level approval, the decision is already made 2) Determine Customer Requirements (needs and wants) Should be very general, vague, and difficult to implement “directly”. The recorded requirements should require further definition. Voice of the customer Should result from genchi genbutsu Words that end in “ability” (maintainability) Phrases that begin with “ease of” (ease of changeover) Words that can apply to all concepts – not just one (not ABS brakes, but brakeability in bad conditions) Include both Quantitative (initial investment) and Qualitative (ease of assembly) Include Basic, Performance, and Delighter Needs (see Kano Model) Kano Model example 2) Determine Customer Requirements (needs and wants) Criteria: Ease of Assembly Maintainability Serviceability Ease of Use Ease of Cleaning Initial Cost On-Going Cost Proven Technology 3) Concept Selection (part 1) Place the Customer Requirements (criteria) into the first column of Concept Selection Form. Determine the relative “weight” of each criterion on a 1 – 5 scale (1 = least important; 5 = most important) Reach consensus on one criterion that is a 5 Reach consensus on one criterion that is a 1 Work down the list of criteria and rate them by comparing to the two extremes. This ensures that the team will use the entire scale. 3) Concept Selection (part 1) Criteria: Ease of Assembly Maintainability Serviceability Ease of Use Ease of Cleaning Initial Cost On-Going Cost Proven Technology Weight 4 3 2 5 1 4 3 2 4) How to Reach Consensus Any stakeholder who is not comfortable with the decision, has the obligation to “block” the decision (except for those who are supporters). It is the obligation of a team member to “block” a decision, if s/he is not 70% comfortable with the decision. If consensus is reached and all participants agree that they are at least 70% comfortable with the decision, there must be 100% commitment from each person. 4) How to Reach Consensus Each individual must test their 70% comfortable, 100% committed feeling by asking themselves: Will I support without conflict? Am I personally satisfied? Have my thoughts and feelings been understood and acknowledged? How do the others feel? Each team member is now accountable for the decision with the team leader holding primary accountability 4) How to Reach Consensus Win-win leaders see life more as a cooperative – not a competitive – arena, and that win-win thinking “is based on a belief that there is plenty for everybody, that one person’s success is not achieved at the expense or exclusion of the success of others.” Stephen Covey 5) Generating Concepts Have small teams, or just individuals: 1) Prius suspensions and hybrid technologies 2) Find/search for different alternatives 3) Develop alternatives designs/concepts Purchased items Suppliers or employees Benchmark alternatives (more on next page) Each team or individual must ensure that they detail the concept 6) Benchmarking Three Main Types: Functional Any industry, best in class, local i.e. benefits, SPC, Product Development Cycle, Benchmarking Requires conceptual thinking, inexpensive, fruitful, easy to get info/data Process oriented Internal Sister companies, departments, work cells i.e. cycle times, quality levels, absenteeism, internal auditing Inexpensive, easy to get info/data, no external focus Process oriented 6) Benchmarking Competitive Your industry and product lines i.e. customer performance metrics and future expectations Hard to get/see information, valuable when received; does not require conceptual thinking Articles, former employees, trade reports, see below Product and Process oriented Product – tear downs, reverse engineering, Mona Lisa, competitive vehicle trip Process – genchi genbutsu, plant trips (if ever possible) 7) Concept Selection (part 2) Team members present and define each concepts so all team members clearly understand each concept and so that each can be fairly evaluated. Provide drawings, sketches, brochures, etc. if applicable. Choose the datum concept (if possible and applicable) If there is an existing concept that is currently in use, choose this concept as the datum. If not, choose the concept that most people are familiar with as the datum. Place the datum concept into the first column to the right of the Weight column. See example. Do not use a datum (tougher to do) Places the other concepts into the columns to the right of the Datum column. CRITERIA IMPORTANCE RATING CONCEPT 1 CURRENT DESIGN Ease of Assembly 4 D Maintainability 3 Serviceability 2 Ease of Use 5 Ease of Cleaning 1 Initial Cost 4 On-Going Cost 3 Proven Technology 2 A T U M TOTAL: DECISION: CONCEPT 2 CONCEPT 3 CONCEPT 4 7) Concept Selection (part 2) The team makes a commitment to each other that the concepts do not belong to any one individual or smaller team. There is no ownership. If any new criterion are brought forth throughout the process, the team may decide to add it to the list with an importance rating. 7) Concept Selection (part 2) The team works with one criterion at a time, comparing each concept to the datum concept, for that criterion. “How does Concept 2 compare with the Datum Concept for “ease of assembly”?” and continue until each concept has been compared to the Datum for that criterion. Move down to the next criterion and continue. As before, consensus must be reached. It is best to evaluate as such when making comparisons: ++ + S -- Much Better Better Same (or A for Average if there is no datum) Worse Much Worse CRITERIA IMPORTANCE RATING Ease of Assembly 4 Maintainability 3 Serviceability 2 Ease of Use 5 Ease of Cleaning 1 Initial Cost 4 On-Going Cost 3 Proven Technology 2 CONCEPT 1 CURRENT DESIGN D A T U M TOTAL: DECISION: CONCEPT 2 CONCEPT 3 CONCEPT 4 S S + + - - + - - S S + S ++ S S - ++ - S + ++ - + 7) Concept Selection (part 2) Computes the totals for each concept (column) by Multiplying the Weight and the Evaluation Rating for each criterion and adding up the totals If “ease of assembly” had an importance rating of “4” and the concept was much better (++) than the datum, then it would receive an “8+” If “proven technology” had an importance rating of “2”and the concept was the same (S) as the datum, it would receive a “0” The total is added up for each column. The concept with the highest positive score is the best choice. If this was a choice of purchasing an item or choosing a supplier and the team cannot change these concepts, then the team’s decision is complete. If the team does have an influence on the design, proceed to the next step. CRITERIA IMPORTANCE RATING CONCEPT 1 CURRENT DESIGN CONCEPT 2 CONCEPT 3 CONCEPT 4 Ease of Assembly 4 D S S + Maintainability 3 + - - Serviceability 2 + - - Ease of Use 5 S S + Ease of Cleaning 1 S ++ S Initial Cost 4 S - ++ On-Going Cost 3 - S + Proven Technology 2 ++ - + +6 -9 +17 A T U M TOTAL: DECISION: 0 √ 8) Synergize for Further Improvement “Synthesis, or putting parts together to form a whole , is the most difficult thinking skill to learn” Seeing David in the Stone James B. Swartz & Joseph E. Swartz 8) Synergize for Further Improvement Synergize concepts when there is team control over the concept. Choose the highest scoring concept as the base and highlights its deficiencies when compared to the other concepts. Modify the base concept by extracting ideas from the other concepts and attempting to institute them into the base concept. Place the synergized concept into the final column and leads the team in evaluating the concept as was previously done. In this case, the team borrowed design attributes from Concept 2 with regard to Serviceability and Maintainability and improved Concept #4 As before, consensus must be achieved. CRITERIA IMPORTANCE RATING CONCEPT 1 CURRENT DESIGN CONCEPT 2 CONCEPT 3 CONCEPT 4 SYNERGIZED CONCEPT Ease of Assembly 4 D S S + + Maintainability 3 + - - + Serviceability 2 + - - + Ease of Use 5 S S + + Ease of Cleaning 1 S ++ S + Initial Cost 4 S - ++ ++ On-Going Cost 3 - S + + ++ - + + +6 -9 +17 + 28 Proven Technology A T U 2 M TOTAL: DECISION: √ 9) Implementation Plan Gain management approval to move on The next step in an A3 process is to develop the implementation plan. If it is a complex project, it is possible to develop multiple implementation plan concepts and go through the same process Implement Rapidly What is Achieved? Far more important than the sound decision that was made through Nemawshi is A great deal of learning up front is achieved before any thing is even planned or implemented Toyota’s greatest accomplishment – becoming a true learning organization!! Questions and Answers Monthly Newsletter? Contact Me …. mike@mikemick.com, 847-401-0442 Services Offered Developing Deming Based Management Systems Anything Lean (inc. Lean Culture, Lean Maturity Assessments, A3, TWI, Nemawashi) Anything Quality (inc. ISO Based QMS’s, FMEA, SPC, DOE) Root Cause Analysis Training Leaning out your QMS Documentation Customized Training and Consulting Keynote Presentations