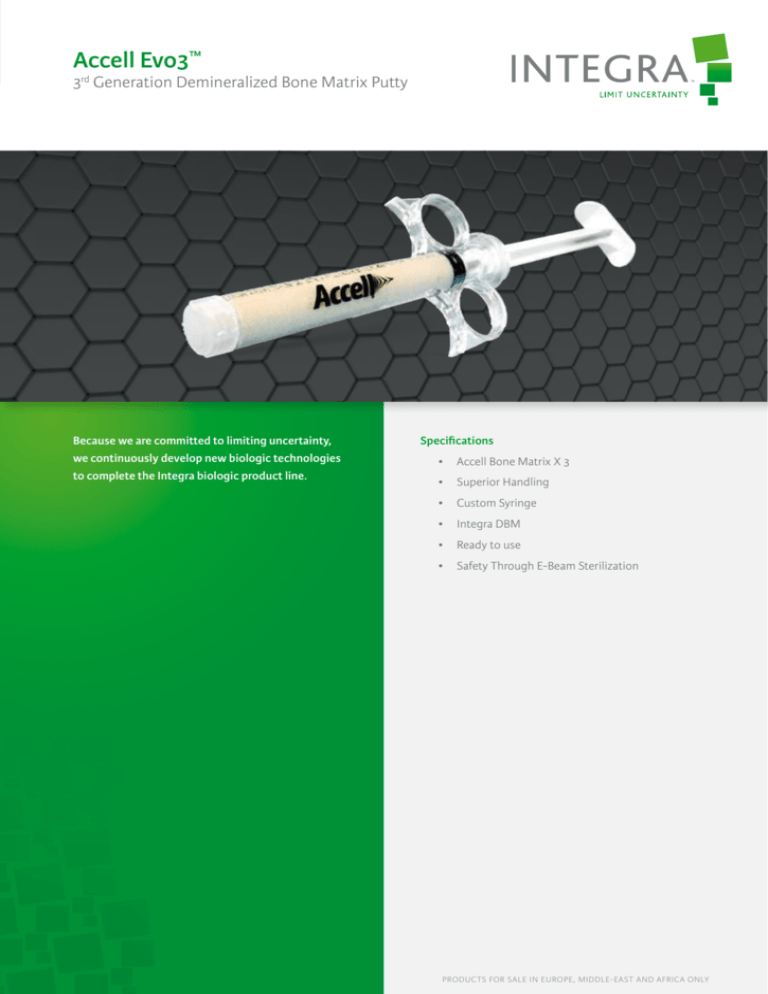

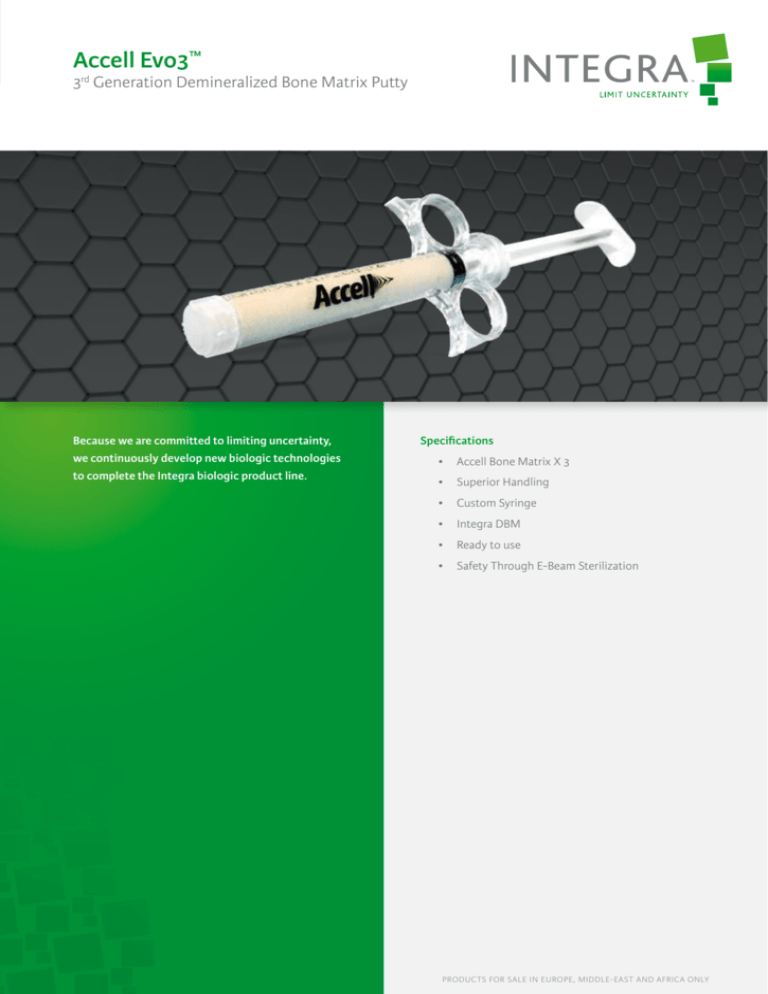

Accell Evo3™

3rd Generation Demineralized Bone Matrix Putty

Because we are committed to limiting uncertainty,

we continuously develop new biologic technologies

to complete the Integra biologic product line.

Specifications

• Accell Bone Matrix X 3

• Superior Handling

• Custom Syringe

• Integra DBM

• Ready to use

• Safety Through E-Beam Sterilization

PRODUCTS FOR SALE IN EUROPE, MIDDLE-EAST AND AFRICA ONLY

Accell EVO3™

3rd Generation Demineralized Bone Matrix Putty

Evolution of DBM to the Demineralized Bone Matrix putty Accell Evo3™

2nd Generation DBM + ABM

1st Generation DBM

DBM

DBM

DBM

ABM

Early 1990’s

First generation Demineralized Bone

Matrix (DBM) formulations combined

standard processed particulate DBM

with an inert carrier for easy handling

and graft containment.

ABM

ABM

3rd Generation Accell EVO3™

Demineralized Bone Matrix

DBM

DBM

2002

A process was developed to transform

particulate DBM into a dispersed form

of DBM. This Accell™ Bone Matrix (ABM)

is blended with traditional particulate

DBM and an inert carrier to create our

second generation products.

ABM

DBMABM

DBMABM

ABM

2008

With Accell Evo3™ Demineralized

Bone Matrix, Integra optimized the

formulation of ABM, DBM, and Reverse

Phase Medicum (RPM). This third

generation product includes three

times the amount of ABM as compared

to second generation products with

even better handling.

Superior Handling2

The optimized formulation of Accell EVO3™ Demineralized

Bone Matrix contains ABM and DBM combined with a unique

poloxamer Reverse Phase Medium (RPM). The result is a

graft material with exceptional handling and containment

characteristics.

The unique RPM carrier becomes more viscous at body

temperatures, while it is less viscous at room temperature.

Because of the RPM’s unique thermoreversible property, the

demineralized bone matrix putty Accell EVO3™ is:

• moldable at the time of application

• packable into virtually any size or shape defect

• mixable with other grafting materials

•

irrigation-resistant

The optimized formulation of Accell EVO3™

Demineralized Bone Matrix results in a robust, moldable

putty that does not stick to surgical gloves.

The unique thermoreversible RPM carrier allows Accell Evo3™

Demineralized Bone Matrix to resist irrigation and graft migration.

Accell EVO3™ ▪ Demineralized Bone Matrix Putty

PRODUCTS FOR SALE IN EUROPE, MIDDLE-EAST AND AFRICA ONLY

Accell EVO3™

3rd Generation Demineralized Bone Matrix Putty

Has your DBM evolved?

Accell™ Bone Matrix X 3

The demineralized bone matrix putty Accell Evo3™ contains 3 times more Accell Bone Matrix (ABM)

than the previous generation of Accell DBM products.*

This dispersed form of DBM offers significantly increased surface area, which provides access to

natural bone proteins.

Superior Handling

Accell EVO3™ Demineralized Bone Matrix incorporates a poloxamer Reverse Phase Medium (RPM),

a highly biocompatible carrier.

This unique thermoreversible carrier allows Accell EVO3™ Demineralized Bone Matrix to meet the needs of

challenging surgical applications where robust handling is essential.

• At room temperature, Accell EVO3™ Demineralized Bone Matrix

is malleable and easily extruded from the syringe

• At body temperature, Accell EVO3™ Demineralized Bone Matrix is more

viscous, resists irrigation and minimizes graft migration

Custom Syringe

The new ergonomic syringe design facilitates easy handling and extrusion of the graft.

The large diameter extrusion is ideal for graft mixing and placement.

Integra DBM: An Expert Approach to DBM Processing

Integra controls the processing of DBM and Accell™ Bone Matrix (ABM) from start to finish in its

state‑of‑the‑art facility. Each lot is tested in a validated in vitro assay to ensure osteoinductive potential.1

Ready to Use

Accell EVO3™ Demineralized Bone Matrix is ready for implantation directly from the syringe.

It does not require any cumbersome or time‑consuming preoperative preparation such as thawing or mixing.

Safety Through E-Beam Sterilization

Integra utilizes electron beam (e-beam) sterilization to ensure product sterility. This process has

been shown to preserve the osteoinductive potential of DBM.1 All products are e-beam sterilized as

the last step in manufacturing prior to being shipped.

*compared to Accell Connexus™ 1

Accell EVO3™ ▪ Demineralized Bone Matrix Putty

PRODUCTS FOR SALE IN EUROPE, MIDDLE-EAST AND AFRICA ONLY

Accell EVO3™

3rd Generation Demineralized Bone Matrix Putty

Pre-Clinical Radiographic Evidence: Comparison of 1st, 2nd, and 3rd Generation DBM Putties on New Bone Formation.3

1st Generation: DynaGraft® II

12 weeks

New bone has formed on both sides.

Fusion between the transverse

processes on the left is complete,

but is not continuous on the right.

3rd Generation: Accell EVO3™

Demineralized Bone Matrix

2nd Generation: Accell Connexus®

12 weeks

12 weeks

2nd Generation DBM resulted in

more new bone formation than 1st

Generation DBM. Both sides have

fused in a continuous manner.

3rd Generation DBM resulted in abundant

new bone formation on both sides,

creating a dense continuous fusion

mass between transverse processes

with new cortical periphery.

The Accell™ Advantage ▪ What’s the Difference?

Accell EVO3™ Demineralized Bone Matrix combines ABM and particulate DBM.

ABM1

Particulate DBM1

Standard Process

Accell Process

Ground Cortical Bone

30x

Standard particulate DBM

is dense and requires more

time to break down. Until

these dense particles break

down, access to natural

bone proteins is limited.

Combined to Form Accell EVO3™

Demineralized Bone Matrix1

30x

Accell™ Bone Matrix (ABM)

is an open-structured,

dispersed form of DBM,

which provides accessibility

to bone proteins without

the need to be broken down.

As a result this creates a

favorable environment for

the formation of bone.

30x

The combination of ABM and

particulate DBM provides for

both immediate and sustained

accessibility to bone proteins which

are important for osteogenesis.4

Accell EVO3™ ▪ Demineralized Bone Matrix Putty

PRODUCTS FOR SALE IN EUROPE, MIDDLE-EAST AND AFRICA ONLY

Accell EVO3™

3rd Generation Demineralized Bone Matrix Putty

What is Our Accell™ Bone Matrix?

Particulate DBM

ABM

Particulate DBM is formed by

removing the mineral component

of ground cortical bone.

Accell™ Bone Matrix is

transformed from particulate

DBM using the Accell™ Process.

At higher magnification, DBM

can be seen as a dense matrix.

At higher magnification,

ABM can be seen as a white,

highly porous matrix.

Particulate DBM consists

of a highly dense matrix of

Type-I Collagen and naturally

occurring growth factors,

with limited accessibility.

ABM consists of an open pore

structure with high surface

area. The resultant scaffold

provides accessibility to bone

proteins, which creates a

favorable environment for

the formation of bone.

Graphically shown, wavy lines represent Type-I Collagen.

The blue and red symbols denote naturally occurring growth factors in bone.

Accell™ Bone Matrix’s increased surface area

provides access to natural bone proteins.

Osteoinductive Potential ▪ In Vitro Measurement5

Accell™ Bone Matrix (ABM) vs. Demineralized Bone Matrix (DBM)

Natural bone protein content of ABM and particulate DBM

was measured in vitro over time using an Enzyme Linked

Immunosorbent Assay (ELISA). The results are shown

graphically and indicate that bone protein was detectable

in a saline solution containing ABM at earlier time points

compared to that of particulate DBM.

The higher surface area and more open pore structure of ABM

provides accessibility to the bone protein, without the need to

be broken down.

This analysis shows that while ABM provided early accessibility

of natural bone protein, particulate DBM provides for

accessibility of natural bone protein at later time points.

Accell EVO3™ ▪ Demineralized Bone Matrix Putty

PRODUCTS FOR SALE IN EUROPE, MIDDLE-EAST AND AFRICA ONLY

Accell EVO3™

3rd Generation Demineralized Bone Matrix Putty

Find out how you can Accell™

Contact Integra™ Customer Service

+1 (949) 595-8710 ▪ www.IntegraOrthoBiologics.com

Description

Catalog Number

2.5 cc syringe

02-5000-025

5 cc syringe

02-5000-050

10 cc syringe

02-5000-100

Indications for use

References

1. Data on file.

2. Compared to previous generations of Integra DBM products.

3. Preclinical data from rabbit spine fusion model on file.

4. Lian J and Stein G,

The Cells of Bone, (1999) Dynamics of Bone and

Cartilage Metabolism (Ed Seibel J).

Accell EVO3™ Demineralized Bone Matrix is intended for filling voids and gaps in the skeletal system

that are not intrinsic to the stability of the bony structure. Accell EVO3™ Demineralized Bone Matrix is

indicated for use as a bone graft extender in the spine, extremities and pelvis, or as a bone void filler in

the extremities and pelvis. The voids or gaps may be surgically created defects or the result of traumatic

injury to the bone.

Warnings and precautions

Accell EVO3™ Demineralized Bone Matrix has been sterilised and keeps its properties during the stated

shelf life in an unopened and undamaged package. The product must be used prior to the expiration date.

5. R&D Systems, Inc.: Quantikine® - BMP‑2 Immunoassay,

For the quantitative determination of bone morphogenetic protein 2

(BMP‑2) concentrations in bone tissue extracts and cell culture supernates.

Do not use if the packaging has been damaged and/or the product has been contaminated. In the

event of contamination, discard the product. Damaged packaging should be returned to Integra

OrthoBiologics. Appropriate placement and/or fixation are critical factors in the avoidance of potentially

adverse effects. As with all biological products, the tissue in Accell EVO3™ Demineralized Bone Matrix has

the potential to transmit infectious agents despite processing treatments, extensive donor screening,

tissue selection and laboratory tests. To date, there have been no reports of experimental or clinical

viral seroconversion using demineralized bone powder. When filling a closed defect, care must be taken

while extruding Accell EVO3™ Demineralized Bone Matrix from the syringe as possible pressurization of

the device could result in fat embolization and/or embolization of the material into the blood stream.

As with any surgical procedure, the possibility of infection exists. Although the production technique

is designed to eliminate antigenic properties of the product, the possibility of such a reaction is

present. Adverse outcomes potentially attributable to the product must be reported promptly to the

manufacturer. If any dissatisfaction with the product performance or packaging occurs, notify Integra

OrthoBiologics immediately and promptly return product and/or packaging. When introducing Accell

EVO3™ Demineralized Bone Matrix, care must be taken to avoid excessive compaction. Overfilling the

implantation site must be avoided to achieve a tension-free closure of the wound.

For further information refer to the product insert.

Integra LifeSciences Services (France) SAS

Sales & Marketing EMEA

Immeuble Séquoia 2 ▪ 97 allée Alexandre Borodine

Parc technologique de la Porte des Alpes

69800 Saint Priest ▪ FRANCE

+33 (0)4 37 47 59 00 ▪ fax +33 (0)4 37 47 59 99

emea.info@integralife.com ▪ integralife.com

Distributed by

Customer Service

International: +1 (949) 595 8710 • Fax: +1 (949) 595 8717 • irvine.cs@Integra-LS.com

IsoTis Orthobiologics

2 Good Year Suite A ▪ Irvine, CA 92618 ▪ United States of America

+1 (949) 595 8710 ▪ fax: +1 949 595 8711 97

©2010 Integra LifeSciences Corporation. All rights reserved. ILS 09-01-014-01-10

PRODUCTS FOR SALE IN EUROPE, MIDDLE-EAST and AFRICA ONLY

Availability of these products might vary from a given country or region to another, as a result of specific local regulatory

approval or clearance requirements for sale in such country or region. ▪ Always refer to the appropriate instructions for use

for complete clinical instructions. ▪ Non contractual document. The manufacturer reserves the right, without prior notice,

to modify the products in order to improve their quality. ▪ WARNING: Applicable laws restrict these products to sale by or

on the order of a physician. ▪ Accell Evo3 Demineralized Bone Matrix, the running man logo, Integra and the Integra logo are

trademarks of Integra LifeSciences Corporation or its subsidiaries.