Tracking Asset Maintenance Costs

advertisement

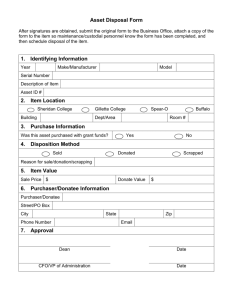

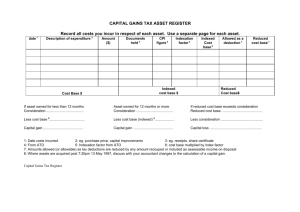

PM Worx - Learning Series Tracking Asset Maintenance Costs I n your day-to-day operations, you’re constantly doing inspections and planned maintenance to make sure your assets keep running smoothly and you don’t get caught suffering from sudden breakdowns. No doubt, we all agree that PM is essential to the economics of running the physical plant. Did you know that emergencies and breakdowns cost an estimated 4% to 20% more than doing the PM in the first place … it depends on the source but even at 4%, it’s too expensive! And, PM is also known to prolong the overall useful life of your equipment saving even far more money in the long run. That being said, corrective maintenance on equipment is inevitable – things do need repair on occasion. The goal, however, is to keep this type of reactive work to a minimum as much as possible. Many of you may have equipment that you’re continually reacting to in order to keep it running like lifts, carts, HVAC equipment, laundry equipment, lawn care items, kitchen equipment, vehicles, floor scrubbers etc. This equipment might not breakdown such that it’s inoperable, but it might need a minor repair to help it work more effectively. You might have an item that’s a real lemon and you do what you can to ensure it keeps operating so you spend that 20 minutes every month to fix a nagging issue. These reactive repairs add up and at some point, it’s wise to weigh the cost of continuing to repair that item versus replacing it altogether. A Real-Life Example Let’s run through an example of a dishwasher that constantly requires repairs and how you’d be able to use PM Worx to analyze the time and money spent to maintain that item. You’ve got a dishwasher in your kitchen that always seems to have a problem. At the start of the year, you had several problems with the door latch not engaging, which prevented the washer from starting. Then, there was a wiring problem that affected the timer and required an outside contractor to come in. Next there was the door seal, the heating element and then finally the water-inlet valve. All of these jobs took time and had Page 1 costs associated with them. By accurately reporting on what resources were used to maintain that dishwasher, you’ll gain valuable insight into whether it’s a better decision to replace it rather than continuing to repair it. PM Worx provides precisely the report you need. To create an asset maintenance history for that dishwasher, you must do two things. First, that dishwasher must have been entered as an ‘asset’ record in PM Worx and second, you must link that fixed asset record to each work order created for the dishwasher repair. Tip: To collect asset data Building an Asset List • Summer student The key building block you need to have in place to be • Back to work programs • Employees on light duty able to accurately analyze • Mobile Worx pocket PC’s your asset maintenance histories is a catalog containing each asset (piece of equipment) in PM Worx. An asset record in PM Worx consists of information like asset description, make, model, serial number, purchase date, purchase cost, warranty expiry, asset tag # and so on. Some of you might have this information in PM Worx. Some might have it in Excel lists or other software and yet others of you might be rolling your eyes at the prospect of building an asset list from scratch. Naturally, if your asset list is already in PM Worx you’re way ahead of the game. If you’ve got your data in Excel or in another software, you’re still in a good position because you can contact us at Windmill and see what it would take to import that data. Another option is to hire someone temporarily (like a summer student) to re-key that data into PM Worx. Speaking of students, if you’re starting from scratch, you might also consider hiring someone temporarily for the job of collecting your asset information too. You can set them up with a clipboard with a template form and assign them to a location each day where they’ll collect the nameplate data, return to PM Worx and key it in. For those of you doing it yourselves, you might consider using Mobile Worx to help get the job done more quickly and easily. www.pmworx.com 877.363.9679 PM Worx - Learning Series It has the ability to use your Pocket PC (handheld device) to enter asset data directly into Mobile Worx so that there’s no need to re-key that information. Linking Assets to Work Orders Once you have your equipment entered into PM Worx, you can link them to both corrective work orders and scheduled work orders. In the dishwasher example, you’d create your work order (or accept the request) as usual, assign the worker and then click the assets tab. From within the asset tab, click the link button and select the dishwasher from the list of assets. The dishwasher is now associated with that work order. When completing a work order with linked assets, the work Work order costs and labor times are divided among the linked assets. order costs and labor times are divided among the linked assets to create a complete asset maintenance cost history. In our dishwasher example, all of the work order costs and times are allocated to our single dishwasher record. Reporting on Asset Maintenance History As you link assets to work orders and begin to develop a rich asset maintenance history you can easily report on how much time & money is being spent to maintain an asset. Another benefit is that you can easily look up historical work orders and determine if a repair/ breakdown is a common occurrence and review past resolutions to the same problem. Here’s how I’d get that report: • Go to Report >> Fixed Asset >> Fixed Assets Maintenance History • Using your Assets filter, select the Dishwasher from the pop-up list of assets. • Enter a date range filter using W/O Call date for Jan 1, 2007 to today’s date. • Now print or preview that report. We can see the list of all work orders performed this year on this report, including costs. So far this year I’ve spent $978 on repairs to this dishwasher. This sounds bad, but it actually gets even worse when you think about the time lost from staff in the kitchen having to scrub dishes the old fashioned way while the dishwasher is out of service. Repair vs Replace Decisions Visibility into what you’re paying to maintain a piece of equipment over a period of time is the key to making well-informed repair vs. replace decisions. Looking at such a small time period as we have in this dishwasher example probably isn’t enough information to base any decisions on. After you’ve been tracking asset maintenance for a couple of years you’ll have enough data to make some reasonable assumptions regarding your annual maintenance costs for your equipment. Once you have this information you can start to assess whether or not it’s financially sound to postpone replacement and continue to repair an asset. The math involved in accurate repair vs. replace decisions can get quite heady. If you’ve got your annual maintenance Using the dishwasher example, let’s say I wanted a history of all work performed on that specific dishwasher since the start of the year. Page 2 www.pmworx.com 877.363.9679 PM Worx - Learning Series costs for equipment you can then pass on this information to your CFO and let them run the numbers. For a good example of how the repair vs. replace decision is made, take a read through this 2 page article from plantservices.com, http:// www.plantservices.com/articles/2003/342.html. Also, be sure to pass the article on to your CFO letting him know that you’re tracking this information for his financial planning. For assistance on entering assets into PM Worx, linking equipment to PM or corrective work orders or reporting, please remember to use our toll-free support @ 1-877-3639679. ▄ Page 3 www.pmworx.com 877.363.9679