OOOOOOOOOOOOOOOOOO CONTROLLING (CO

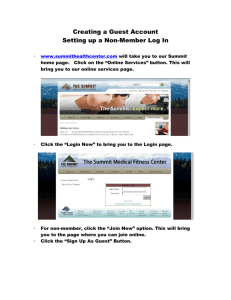

advertisement