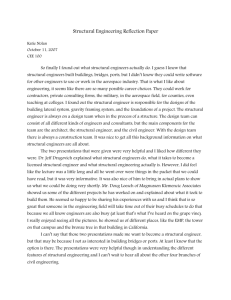

Engineering Body of Knowledge - National Society of Professional

advertisement