CH243: Lab 4 Synthesis of Artificial Flavorings by Fischer Esterification

advertisement

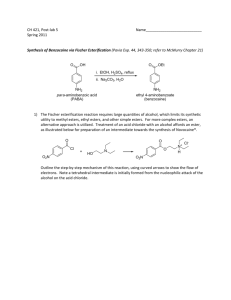

CH243: Lab 4 Synthesis of Artificial Flavorings by Fischer Esterification PURPOSE: To prepare esters by reaction of carboxylic acids and alcohols. To modify a known procedure to prepare an unknown. DISCUSSION: Volatile esters usually have pleasant, fruity odors. The characteristic fragrance and flavor of fruits and flowers are due, in most cases, to mixtures of esters. The mixture of esters responsible for a natural flavor is usually complex and difficult to duplicate. However, if the flavor is attributed to a major component then a synthetic ester of the same structure can be substituted for the natural flavor at a fraction of the cost. For this reason, esters are used in the food, flavor, and fragrance industries. A formula for artificial pineapple flavor is given below. The composition of the mixture is very important to duplicating the flavor; and it should also be pointed out that our perceptions of an ester’s smell may depend on its dilution. ARTIFICIAL PINEAPPLE FLAVOR Pure Compounds allyl caproate isoamyl acetate isoamyl isovalerate ethyl acetate ethyl crotonate ethyl butyrate terpinyl propionate caproic acid butyric acid acetic acid % 5 3 3 15 5 22 3 8 12 _5 81 Essential Oils oil of sweet birch oil of spruce balsam Peru volatile mustard oil oil cognac concentrated orange oil distilled oil of lime % 1 2 4 1 5 4 2 __ 19 Many esters can be conveniently prepared by refluxing a mixture of a carboxylic acid and an alcohol in the presence of a strong mineral acid such as sulfuric acid or hydrochloric acid. This reaction is shown by the following equilibrium equation: O O R C OH + HO R' H+ R C O R' + H2O The acid catalyst increases the rate at which equilibrium is reached but does not affect the position of the equilibrium. In order to shift the equilibrium to the right and prepare the ester in reasonable yield two measures can be taken: 1) use a large excess of the alcohol, or 2) remove either the water or ester as it is formed. The most common method of the two, especially when the alcohol is inexpensive as is the case for methanol and ethanol, is to use an excess of the alcohol. This procedure is call Fischer Esterification. CH243 Synthesis of Esters (3/11) 1 The structures and approximate smell of a few esters follow: Name isoamyl acetate Flavor banana Structure O CH3 methyl butyrate CH3 C O CH2CH2CHCH3 apple O CH3CH2CH2 n-propyl acetate pear O CH3 isobutyl propionate C O CH2CH2CH3 rum O CH3CH2 ethyl butyrate CH3 C O CH2CHCH3 pineapple O CH3CH2CH2 octyl acetate C O CH3 oranges C O CH2CH3 O CH3 C O CH2(CH2)6CH3 INSTRUCTION: In this experiment you are to synthesize an ester of your choice pretending that it has never before been made. A common practice in frontier organic synthesis is to model procedures for the preparation of a new compound after the procedures of a similar reaction. There are many sources for reaction procedures from which you can model your synthesis. Following are known procedures for preparation of two common esters. Your task is to synthesize one of a variety of esters by adapting one of these or another Fischer Esterification procedures to fit your own reaction. For starters determine the molar proportions you want to use in your reaction by modeling after those in the known procedures. The procedures given require refluxing. The advantage to refluxing is that a constant temperature is maintained in the flask and the reaction can reach equilibrium without any materials escaping at the higher temperature of the medium. As this is hypothetically a frontier synthesis of an ester having never before been made you will want to: Keep appropriate records of your research in your lab notebook. Characterize your product by using mp/bp, properties IR, NMR etc. as needed. Analyze the cost effectiveness of your reaction. Analyze the “greenness” of your synthesis using atom economy and comparative data as learned in previous experiments. CH243 Synthesis of Esters (3/11) 2 SAMPLE PROCEDURES: 1. Isoamyl acetate (banana) O CH3 C OH CH3 + HO O H+ CH2CH2CHCH3 CH3 CH3 C O CH2CH2CHCH3 + H2O 1. Mix 6 mL of isoamyl alcohol and 10 mL of glacial acetic acid in a 100 mL round bottom flask. Carefully add 1 mL of concentrated sulfuric acid while swirling. 2. Add either boiling chips or a stirring bar and assemble the apparatus for reflux. Gently reflux with stirring for 30 minutes. 3. Allow the flask to then cool at room temperature for about five minutes and then cool in an ice bath. 4. Pour the mixture into a separatory funnel and add 10 mL of cold water (made from ice and distilled water chilled in an ice bath). Shake the layers and allow them to separate. Remove and discard the lower, aqueous layer but keep the top organic layer. 5. Add another 10 mL portion of cold water to the organic oil, shake the layers and separate them again. Discard the aqueous layer but keep the top organic layer. 6. Wash the organic layer with 10 mLs of saturated sodium bicarbonate (NaHCO3), separate, and then wash once with it with 10 mLs of saturated sodium chloride solution (NaCl). 7. Transfer the organic layer to a 125 mL Erlenmeyer flask and dry it for five minutes over magnesium sulfate (MgSO4). Filter the dried solution. 8. Determine the weight of your crude product. If so instructed purify the banana oil by simple distillation. 9. Calculate the yield, the % yield, and put the sample in a labeled vial to turn in. 2. n-Propyl acetate (pear) O CH3 O C OH + HO CH2CH2CH3 H+ CH3 C O CH2CH2CH3 + H2O 1-3. Use the above recipe for banana flavor but use 8 mLs of 1-propanol instead of the isoamyl alcohol. Use the same amounts of the other reagents. 4-6. Instead of washing with water, use 15 mL portions of saturated sodium chloride and then three 10 mL portions of saturated sodium bicarbonate, and finally again with 10 mL sodium chloride. 7-9. Same as above. CH243 Synthesis of Esters (3/11) 3 CH243 Synthesis of Esters (3/11) 4 Lab 4: Synthesis of Esters Name__________ Prelab Questions: 1. On the back write out the step by step mechanism for formation of your ester. Include action of the catalyst. 2. A. What is the purpose for the saturated sodium bicarbonate in the purification steps? (be specific) B. Write the reactions of sodium bicarbonate with components of the product mixture. 3. A. Why do some procedures have you wash your product with a saturated sodium chloride solution? Explain what it is doing? B. Why do some procedures have you add anhydrous sodium sulfate or anhydrous magnesium sulfate to your product before distillation? Explain what these are doing? 4. Some esters can be isolated by distillation directly from the reaction mixture but some isolation of some esters require neutralization and extractions prior to purification by distillation. Explain why? CH243 Synthesis of Esters (3/11) 5 CH243 Synthesis of Esters (3/11) 6 Lab 4: Synthesis of Esters Name__________ Postlab Questions: 1. Analyze the cost effectiveness of your reaction. Make a table of costs of reagents Determine the $ per mL or g of product produced. 2. Analyze the “greenness” of your synthesis using atom economy and comparative data as learned in previous experiments. CH243 Synthesis of Esters (3/11) 7