Microscope Systems

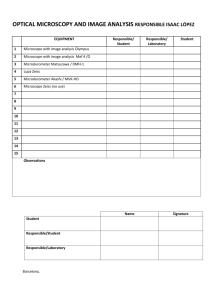

advertisement