Fermentation in the Yeast Saccharomyces cerevisiae

advertisement

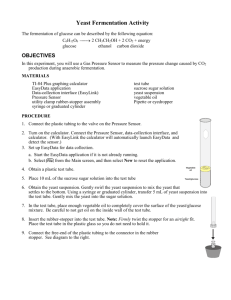

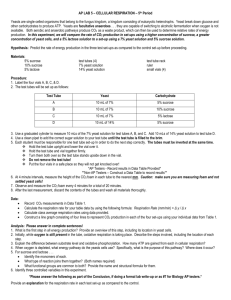

Fermentation in the Yeast Saccharomyces cerevisiae BY DR. SUSAN PETRO Introduction Yeast are simple unicellular organisms belonging to the Kingdom Fungi. They are relatives of molds, mildews and mushrooms. Like all organisms, yeast need energy to do the work of living (synthesis, transport, reproduction, etc.) They obtain this energy through a process called cellular respiration, which involves the oxidation of organic molecules. Some of the energy produced by this oxidation is stored in the chemical bonds of adenosine triphosphate (ATP) - the energy currency of the cell. There are two types of cellular respiration - aerobic and anaerobic. Aerobic respiration In most cells, including yeast, respiration begins in the cytoplasm with the oxidation of glucose to pyruvate by a ten-step process called glycolysis. This process requires a ‘push’ of two ATPs to get started, but once rolling it produces four ATPs directly by a process called substrate level phosphorylation. Additional energy is stored by adding high-energy electrons to the electron carrier NAD+ (nicotinamide adenine dinucleotide) converting it to NADH + H+. This process is called reduction (the positive charge is being reduced by the addition of negatively charged electrons). Glycolysis occurs with or without the presence of oxygen. If oxygen is present, most organisms (including yeast) continue respiration by oxidizing the two pyruvates produced by glycolysis to CO2 via the formation of acetyl CoA and then the Kreb’s citric acid cycle. Two additional molecules of ATP are produced directly by the Kreb’s cycle, again by substrate level phosphorylation. The formation of acetyl CoA and the Krebs cycle store additional energy in NADH + H+ and FADH2 (flavin adenine dinucleotide). Again this energy is stored by reduction, the process of adding high-energy electrons to the NAD+ and FAD converting them to NADH + H+ and FADH2. NADH + H+ and FADH2 later transfer their high-energy electrons to the series of complexes comprising the electron transport chain. As the electrons pass down the electron transport chain the energy they lose is trapped as usable energy in ATP through the mechanism of chemiosmosis. Oxygen is the final electronacceptor in the electron transport chain, which is why the Kreb’s cycle and electron transport chain cannot proceed if oxygen is absent. The entire process of aerobic respiration consisting of glycolysis, acetyl CoA formation, the Krebs citric acid cycle, the electron transport chain and chemiosmosis produce 30 - 32 ATPs for each molecule of glucose depending on the type of cell. In heart and liver cells for example 32 ATPs are produced while in brain cells 30 ATPs are produced. 1 Anaerobic respiration Yeast are classified as facultative anaerobes, which means they are capable of both aerobic and anaerobic respiration. When oxygen is unavailable, yeast carry out fermentation, a type of anaerobic respiration. The difference between aerobic and anaerobic respiration lies in how the NADH + H+ produced in glycolysis is converted back to NAD+. In aerobic respiration the hydrogens (electrons) from NADH +H+ are passed to oxygen in the electron transport chain yielding approximately 2.5 ATPs per NADH + H+ while in fermentation the hydrogens (electrons) are passed on to acetaldehyde to form ethanol yielding no ATPs per NADH + H+ as follows: Step 1 - Pyruvate (from glycolysis) → Acetaldehyde + CO2 Step 2 - Acetaldehyde NADH + H+ Ethanol NAD+ Humans have made use of the byproducts of fermentation for centuries - the CO2 to make bread rise and the ethanol in beer and wine. From the yeast's viewpoint both CO2 and ethanol are waste products and in fact ethanol is toxic, killing the yeast organisms when it reaches a concentration between 14-18%. This is why the percentage of alcohol in wine and beer doesn't exceed approximately 16%. In order to produce beverages with higher concentrations of alcohol (liquors), the fermented products must be distilled. Fermentation produces only 2 ATPs per glucose molecule (via glycolysis). Aerobic respiration produces 30 - 32 ATPs from a molecule of glucose. Thus the ability of yeast to live in the absence of oxygen comes at a price - fermentation produces 19-fold fewer ATPs per glucose molecule than does aerobic respiration. Purpose - Part 1 In this exercise the effect of the following compounds on fermentation rate in bakers’ yeast (Saccharomyces cerevisiae) as measured by CO2 production will be observed. The genus name of this yeast means sugar fungus and the species epithet is Latin for beer as this species is also used in brewing. It is the official state microbe of Oregon. Glucose will be used as the substrate except in the lactose tube. In the lactose tube lactose will be the substrate. • Lactose - a disaccharide composed of glucose and galactose • MgCl2 - provides Mg++, a cofactor in three of the enzymes of glycolysis: phosphofructokinase (step 3), enolase (step 9) and pyruvate kinase (step 10) • NaF - an inhibitor of the enzyme enolase, the catalyst for step 9 of glycolysis • In addition, the effect of pH on fermentation rate will be observed. 2 Each table is assigned one of the variables to determine its effect on fermentation rate in the yeast, Saccharomyces cerevisiae. Lab Table 1 – Is yeast necessary for the production of CO2? Procedure – Part 1 Measure 50 ml of pH 4 buffer and place in a beaker. Add 1.25 grams of yeast to the pH 4 buffer in the beaker. Now add 2.5 ml of 5.0% glucose solution to the beaker. Mix well with a glass stir rod and add the mixture to a fermentation tube. Determine what would go in the control fermentation tube for this experiment. Prepare a control tube. Follow post-mixing directions below. Lab Table 2 – What is the effect of pH on the production of CO2 by Saccharomyces cerevisiae? Procedure – Part 1 Measure 50 ml of pH 4 buffer and place in a beaker. Add 1.25 grams of yeast to the pH 4 buffer in the beaker. Now add 2.5 ml of 5.0% glucose solution to the beaker Mix well and add the mixture to a fermentation tube. Repeat directions for pH 2 buffer and pH 6 buffer. Follow post-mixing directions below. Lab Table 3 – What is the effect of MgCl2 on the production of CO2 by Saccharomyces cerevisiae? Procedure – Part 1 Measure 50 ml of pH 4 buffer and place in a beaker. Add 1.25 grams of yeast to the pH 4 buffer in the beaker. Now add 2.5 ml of 5.0% glucose solution to the beaker. Add 5.0ml of 0.1M MgCl2 to the beaker. Mix well and add the mixture to a fermentation tube. Determine what would go in the control fermentation tube for this experiment. Prepare a control tube. Follow post-mixing directions below. Lab Table 4 – What is the effect of NaF on the production of CO2 by Saccharomyces cerevisiae? Procedure – Part 1 Measure 50 ml of pH 4 buffer and place in a beaker. Add 1.25 grams of yeast to the pH 4 buffer in the beaker. Now add 2.5 ml of 5.0% glucose solution to the beaker. Finally add 5.0ml of 0.1M NaF to the beaker. Mix well and add the mixture to a fermentation tube. 3 Determine what would go in the control fermentation tube for this experiment. Prepare a control tube. Follow post-mixing directions below. Lab Table 5 – What is the effect of using lactose as a substrate instead of glucose on the production of CO2 by Saccharomyces cerevisiae? Procedure – Part 1 Measure 50 ml of pH 4 buffer and place in a beaker. Add 1.25 grams of yeast to the pH 4 buffer in the beaker. Now add 2.5 ml of 5.0% lactose solution to the beaker. Mix well and add the mixture to a fermentation tube. Determine what would go in the control fermentation tube for this experiment. Prepare a control tube. Follow post-mixing directions below. Post-mixing directions for all tables. • • • • • • Make certain that you tip the fermentation tube when you fill it so the blind end is completely filled with fluid. Insert a foam plug in the outlet of each tube. Put the tubes on the tray on your lab bench and tape the bases of the tubes to the tray so they don’t accidently tip over. Place the tray with its fermentation tubes into the 29ºC incubator. Every 10 minutes for 60 minutes measure the height in millimeters of the column of accumulated CO2. Your lab rulers are calibrated in centimeters i.e. the 1 demarcation is 1 centimeter. The ten lines between zero and 1 are millimeters. Remove your tray of fermentation tubes from the incubator to do the measurements so the incubator doesn’t cool down. Putting each fermentation tube on a flat surface gently swirl the contents to release any gas trapped in the base by the settling yeast organisms. 4 • Measure from the bottom of the gas produced (which may be just a few bubbles at first) to the top of the tube. Do not confuse the demarcation line between the settled yeast organisms and the fluid above them with the demarcation line between the fluid and the gas above it. Line up the zero on the ruler with the bottom of the meniscus of the fluid. To read the measurements it might be helpful to then place an index card on the top of the blind end of the fermentation tube parallel to the table top so it hits the ruler at the measurement. See illustration right. • Transfer all the class data from the whiteboard to Results Tables 1 and 2 Results Table 1 Time (min) CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) Tube with yeast Control Tube MgCl2 MgCl2 control NaF NaF control Lactose Lactose control 0 10 20 30 40 50 60 Results Table 2 Time (min) 0 10 20 30 40 50 60 CO2 Production (mm) CO2 Production (mm) CO2 Production (mm) pH 2 pH 4 pH 6 5 Part 2 In this part of the exercise the effect of temperature on fermentation in the yeast Saccharomyces cerevisiae will be observed. Procedure - Part 2 • There is an index card on each table with the temperature at which your final fermentation tube will be incubated. • Check the thermometer inside the refrigerator or incubator to be sure that the temperature is what it says outside. If not then record the actual temperature. • Set up the final tube according to Mixing Table 2 below. The pre-measured buffers to make the yeast solution are in the flasks in the incubators or refrigerator at your assigned temperature. • Take 2 grams of yeast and your fermentation tube with the glucose in it to the incubator/ refrigerator at your assigned temperature. • If you were assigned room temperature your buffer is on your table and you must record what the room temperature is. • Add the 2g of yeast to the buffer flask, mix and add to the fermentation tube. As previously, make sure the blind end of the tube is full of the yeast suspension. • Work fast so the temperature does not alter too much. Mixing Table 2 • • • • Tube 5.0% Glucose 1 2.5ml pH buffer 4 in incubator/frig/on lab bench depending on which temp your table was assigned 50ml Insert a foam plug and return the fermentation tube to the incubator/refrigerator. Every 10 minutes for 60 minutes measure the height in millimeters of the column of accumulated CO2. Write your results on a chart on the whiteboard. Transfer all the class data from the whiteboard to Results Table 2. Results Table 2 Time (min) CO2 Production (mm) at 4°C CO2 Production (mm) at Room temp ____°C 0 10 20 30 40 50 60 6 CO2 Production (mm) at CO2 Production (mm) at CO2 Production (mm) at 37°C 55°C 70°C • • At the end of the experiment thoroughly rinse out your fermentation tubes. Do not use soap. Rinse out and save the foam plugs. Write up • • • • • Write up this exercise as a laboratory report. This would of course include graphing of your data and evaluation of your slopes (the b in the equation y = bx + a) to determine the effect of the various treatments on the rate of the reaction. Make six separate multi-line linear regression graphs one for each of the following: 1. yeast tube and its control 2. MgCl2 tube and its control 3. NaF tube and its control 4. lactose tube and its control. 5. one for the three pHs (there is no control tube for pH as you can’t have a solution with no pH) 6. one for the five temperatures You will then do a seventh graph 7. A derivative graph of fermentation rates for the various temperatures. (Hint: you did two derivative graphs for the turnip peroxidase lab.) After observing the effect of NaF on fermentation rate can you think of a reason why many toothpastes have fluoride in them? (Put in your discussion on NaF) Latest Revision – April 23, 2014 7